ORIGINAL ARTICLE

RIBEIRO, Jessiel de Moura [1]

RIBEIRO, Jessiel de Moura. The problem of Supply Chain Management in the face of the impacts of Covid-19 and the resumption of growth. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year. 07, Ed. 08, Vol. 07, p. 28-47. August 2022. ISSN: 2448-0959, Access link: https://www.nucleodoconhecimento.com.br/business-administration/impacts-of-covid-19

ABSTRACT

Discussing the Supply Chain implies considering all the planning and structuring necessary to fully serve the final customer, demanding decision-making involving the strategic, tactical and operational aspects of an organization. With the emergence of the Covid-19 pandemic, the supply chain of different companies around the world became disorganized, causing an alarming shortage, in addition to the shortage of manpower for work in all segments. In this perspective, the question that arises is: how to promote the resumption of industry, commerce and services in the post-pandemic global level? As an objective, it is intended to investigate possible solutions to reorganize the supply planning flow of companies and resumption of the full functioning of the production chain in the face of the demands of its clientele in the post-Covid-19 pandemic. This original article was developed using the bibliographic research methodology, discussing the stoppage of Supply Chain processes, caused by the Covid-19 pandemic and the consequent drop in supply. There was a need to create and implement resilient supply chains, in the face of eventual drastic occurrences; development/implementation of technological collaboration through high-performance tools/platforms for better management of Supply Chain processes, using the blockchain system; promoting the training of individuals and teams.

Keywords: Covid-19 Pandemic, Supply Chain, Post-pandemic supply resumption.

INTRODUCTION

Supply Chain Management (SCM) practices comprise the set of processes interconnected in a chain that begins with the purchase of raw materials, production, storage, internal movement, transport and distribution to the final consumer (NEOWAY, 2021).

With the advent of the Covid 19 pandemic that promoted, in a short period of time, an unprecedented global crisis throughout this century, there was a serious interruption in the flow of goods necessary for the daily lives of individuals in the format known until then, impacting all the production and distribution chain, and with that, causing the deceleration of the world economy. The different sectors of society then began to experience health, social and economic problems (GERDEMAN, 2022).

Trade between the United States and China was greatly affected, as workers became sick and factories were forced to stop their activities (HEISE, 2020).

At present, the reduction of severe forms of the disease and of contagion is emerging, despite the high numbers of deaths recorded around the world. This fact is due to the satisfactory results obtained by the adoption of the necessary measures to fight the disease, such as social isolation and other sanitary measures adopted, allied to the mass vaccination that covered most of the nations.

The impact of the shortage of inputs and goods in all segments caused a reduction of 2% in the annual growth of the US economy between July and September 2021, contrary to previous forecasts by experts who pointed to the house of 7% per year. Also contributing to this drop in economic growth is the increase in prices of fuel, food, rents and basic items for the survival of North Americans (CBS NEWS, 2021).

However, difficulties persist in different organizations and their concentrated effort in their search for the necessary manpower to fill the professional opportunities still open, since the labor market was strongly disrupted by the disease (CBS NEWS, 2021). Added to this is the fact that the recent resumption of business has taken many companies by surprise, which, in the face of the pandemic, reduced their purchases and productivity, but which, in the face of the soaring consumer demand, verified their shortages to promptly meet the resurgence of demand (GERDEMAN, 2022).

In this perspective, this original scientific article, whose methodology was bibliographic research, intends to answer the following question: how to promote the resumption of industry, commerce and services in the post-pandemic global level?

In response to the proposed problem, the objective of this study is to identify possible solutions to reorganize the supply planning flow of companies and resume the full functioning of the production chain in the face of the demands of its clientele in the post-Covid-19 pandemic.

EMERGENCY OF COVID-19

It is not up to humanity to put into perspective the millions of lives lost by contagious diseases that quickly spread across many continents, including Smallpox, during the third century (from January 201 AD to December 300 AD); the Black Death in 1347, Cholera in 1817, the Bubonic Plague in 1855, the Measles Pandemic in 1875, the Spanish Flu in 1918, the Asian Flu in 1957, and the Swine Flu (H1N1) in 2009, as indicated by the portal from the University of Medicine of Lisbon (UL, 2020).

Even so, the Covid-19 pandemic is considered “the greatest threat to global public health of the century”, an event that promoted imbalance and deficiencies in economic, political and social progress in all countries (SILVA, 2020, p. 448).

A tragedy of unprecedented proportions, Covid 19 caused the triggering of a world order crisis affecting all sectors of human life, also exerting strong pressure on the productive capacity of the different industrial sectors around the world, since at the same time As the contagion grew, the offer of products and services was slowly paralyzed (SILVA, 2020).

Before the official announcement issued by the Chinese government to inform the World Health Organization (WHO) about the emergence of the new coronavirus, countries importing goods produced in China were already beginning to suffer from the significant drop in the supply chain from that country (YOSHIDA, 2020, p. 12).

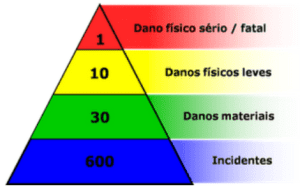

Interruptions in the flow of products and inventories, classified by experts as serious interruptions – when manufacturers partially or totally closed/paralyzed their activities, airports adopted severe restrictions, there was a shortage of equipment and supplies – in themselves, were events that impacted global supply networks, also caused by the social isolation that is so necessary to contain the spread of the new coronavirus (YOSHIDA, 2020, p. 12).

China, which over time has become the largest local and global center in the production of raw materials and spare parts for different segments of the industry, has become the main critical supplier for the machinery, telecommunications, precision instruments sectors, etc. (CAI and LUO, 2020).

Wuhan was the Chinese city most affected by the new coronavirus, the initial epicenter of the epidemic, whose production comes from large companies in the automotive and semiconductor sector, so necessary to the sector’s giants, including Foxconn, Dongfeng, Motor Group, Honda and General Motors, which faced a sharp drop in their business (CAI and LUO, 2020).

The spread of Covid-19 quickly reached the provinces of Guangdong, Zhejiang and Jiangsu, a region where many manufacturing companies are concentrated, causing the production of cars, cell phones and other products to gradually decrease, due to the lack of raw materials, parts of replacement, and also the lack of manpower (CAI and LUO, 2020).

The subsequent contagion by the new coronavirus caused the closure of numerous factories in different countries, in the face of actions to block the movement of people and means of transport, including sectors of the automobile, electronics and even pharmaceutical industries. As a result, the risk of bankruptcy of numerous medium and small companies has become a reality in the medium term (CAI and LUO, 2020).

The impacts of Covid-19 on the world supply process occurred in two phases, described by Cai and Luo (2020): in phase 1, between February and March 2020, gradual changes began to occur in all production processes in China, relative to to the supply of raw materials and spare parts, initially causing delays in the delivery of import orders. Faced with the continuous growth of contamination of people, in phase 2, the production processes were interrupted.

It should be noted that China is considered “a major consumer of global commodities and agricultural products, and manufacturing disruptions in China have spread through global supply chains” (TWINN et al., 2020, apud SILVA, 2020, p. 450). ).

The reduction in the growth of the Gross Domestic Product (GDP) impacted the global supply chain in a comprehensive way, regarding the production and supply of inputs, as well as the offer of industrial products and services in general, due to the global crisis installed, as explained Steve Rick, chief economist at insurer Cuna Mutual Group (CBS NEWS, 2021).

SUPPLY CHAIN: STEPS, TYPES AND SCOPE

According to Pessoa et al. (2017, p. 176), the new world reality, represented by “globalization, electronic commerce and automations” allows consumers of all standards and purchasing power countless experiences not imagined before, at the same time that organizations of different sizes seek expand your business, whether in physical or electronic points of sale. The fact is that all these aspects imply the management of the supply chain, as well as the care with the risks inherent to such management.

The concept of Logistics emerged in France around 1917, described in the book “Logística Pura: a ciência da preparação para a guerra”, written by the then Lieutenant Colonel Thorpe, a United States Marine. In that book, the “strategies of war, whose objective was to take care of the stock, maintenance and distribution of different materials, such as food, medicine, weapons, clothes and means of transporting them” were described and carries out several projects (FUNDACE, 2019).

But there was a gap between the release of the aforementioned book in 1917 and the strengthening of the Logistics area in the business context, which only occurred from 1970 onwards, when it began to encompass aspects such as efficient planning, inventory and product transport (FUNDACE, 2019) .

According to Yoshida’s definition (2020, p. 17-8), logistics is the area that consists of the strategic management of the activities of acquisition, movement and storage of materials, “aiming to maximize gains – present and future – through the inflection of costs in fulfilling orders”. It also comprises:

o serviço ao cliente, relacionado ao tráfego e meios de transporte, armazenagem, localização da planta fabril e seus depósitos, o controle de inventário, o processamento de pedidos, a aquisição de materiais e sua movimentação e distribuição, suprimento, entrada e saída de materiais, devolução de mercadorias e previsão de volume de pedidos, atendendo o cliente de forma eficiente (…) (YOSHIDA, 2020, p.17-8).

Logistics aims to allow greater profitability of services to customers and consumers, enabling the best flow and greater added value of its products to its customers (YOSHIDA, 2020).

The evolution of this concept led to the emergence of Supply Chain Management (SCM), integrating all the processes involved in Logistics with others necessary for the full management of this sector (NEOWAY, 2021).

SCM has become a fundamental strategy for improvements in the operational systems of organizations, allowing the generation of competitive advantage through cost reduction in the production phases, innovations in processes and delivery to the final consumer with higher quality (NEOWAY, 2021) .

However, there are risks related to this Management, which are subdivided into: operational risks, threats to investments in inventory and supply chain costs (YOSHIDA, 2020).

According to Neoway (2021), among the types of supply chains are:

- Totally flexible: focuses on fast delivery, as is the case with e-commerce customers. It is used by high-demand market areas, facing consumers with greater purchasing power;

- Agile: focused on quick responses to unpredictable demands, for example, industrial inputs. It is used in non-loyal consumer markets that require fast delivery but offer high rejection at high prices;

- Lean: its focus is on efficiency, economy of scale and low cost of production and delivery, represented for example by office supply suppliers. Used in B2B type businesses, it usually has customers looking for good prices, with fast and quality service;

- Continuous replenishment: With a focus on developing consumer loyalty for reliable products and services, one can mention bar beverage suppliers as an example. Used for markets whose demands are predictable, and customers loyal to their suppliers.

The differences between one concept and another consist in the fact that Logistics is a specific approach that involves the steps between storage and transport, while Supply Chain Management involves all the management between companies, to highlight: suppliers , distributors, warehouses, consumers, etc. (FUNDACE, 2019).

In turn, there is the Risk Management Supply Chain (SCRM). According to Lima Jr. et al. (2021, p.279), consists of the “intersection of knowledge between Risk Management and Supply Chain Management”. These are risks inherent to geographic issues, which impact supply chains, which are linked to the social contexts and demands of different countries in their supplier/buyer relationships.

Lima Jr. et al. (2021) teach that such risks refer to the nature of the risk or the effectiveness of the strategies of different companies, countries, etc., insofar as they may or may not compromise business and the viability of commercial projects. These authors describe five risk factors, to be highlighted:

- Transport risks: possible problems during the transport of goods, related to delays or damage to the products;

- Information and forecasting risk: possible errors in information and demand forecast, such as errors related to order documentation; order entry and information system errors; urgent requests for orders and changes by customers and proper stock maintenance;

- Supplier risk: possible sudden bankruptcy of a supplier; shortages and defects caused by the supplier’s inadequate production; deficiencies in responding to urgent requests;

- Environmental risk: consist of possible operational changes to the SCM; price fluctuations related to rising raw material prices and inflation; unmet supply and demand due to insufficient raw materials; changes in regulations, laws and related policies; technological changes;

- Destructive risk: relating to sudden and unexpected natural disasters and accidents, such as epidemics, fires, traffic accidents, strikes and closures of ports and airports.

To the five risks described, Gerdeman (2022) adds a sixth risk, related to the numerous resignation requests of North American workers, which occurred for different reasons in the post-pandemic period.

MULTILATERALISM AND THE GLOBAL SUPPLY CHAIN

Multilateralism is the term that means the conception of structures that tend to work in a universal way among the parts that integrate it. It is similar to the purpose of bodies such as the International Monetary Fund (IMF), the United Nations (UN), the International Labor Organization (ILO), among others, each of them subject “to a certain system of coordination of relations between different states, to meet certain objectives” (FONSECA JR, 2019).

Fernandes and Simão (2020 p. 18-19) explain that multilateralism as a “structuring principle in international relations”, was born in the 20th century and can be defined as “the practice of coordinating national policies between three or more States, through ad hoc or institutions”.

In turn, regionalism and its multiple forms are based on the basis of coordination processes between different states, with the exception of the European Union (EU). It is also similar to various institutions, including the Organization of American States (OAS), Association of Southeast Asian Nations (ASEAN), North Atlantic Treaty Organization (NATO), or the Atlantic Alliance, etc. (FONSECA JR, 2019).

It is also worth mentioning the concept of multipolarity, defined by Fernandes and Simão (2020) as the distribution of power factors in the different poles, a power that is usually concentrated in countries considered by the international system as world powers. Multipolarity differs from multilateralism, which is the arrangement between countries interested in agreements with each other, because it is related to issues related to the distribution of power.

Multilateralism arises from the need of different nations and their demands for agreements on the supply of inputs, products, commodities, etc. These are agreements that can be made according to regional, bilateral and even plurilateral preferences, and their signatories must remain faithful to the principles of free trade (TIRONI, 1990).

The rules relating to multilateralism and its inspection are the responsibility of the World Trade Organization (WTO), based on technical regulations developed from other existing agreements. Among the world’s largest poles of power are the United States, China and the European Union (EU). Thus, in accordance with technical regulations, other countries can choose or combine their choices along the production chain of one group or another, according to their regional needs and interests (TIRONI, 1990).

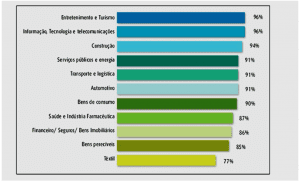

In this way, China, USA and Germany became commercially linked, starting to produce/export to North Asia, North America and Western Europe, respectively, while South Korea, Japan and Singapore rose to the status of high importance in production/ supply of products destined for the global chain, even depending on its geographic location, since its exports represent 40% of intermediate products, according to data tabulated by KPMG consultancy, a renowned independent company specialized in auditing, consulting services and tax analysis (TIRONI , nineteen ninety).

With regard specifically to the United States and China, Heise (2020) argues that it is a trade relationship whose main characteristics are protectionism and uncertainty.

IMPACTS OF UNSUPPLY IN THE UNITED STATES

With the Covid 19 pandemic, there was a sharp drop in the supply of different types of products destined for the various countries. It was a time when the United States halved its imports from China, between January and March 2020, directing part of the volume of its purchases to non-Chinese suppliers (HEISE, 2020).

At present, two years after the Covid 19 pandemic, North Americans are still faced with understocked shelves in different types of stores, whether food and supermarket items, appliances and even toys, among many others (KAVILANZ, 2022).

It is a shortage that even affects convenience stores, which usually work as alternative commercial points and even offer food items, among others common to supermarkets. There have been cases of stores located in larger cities or secondary markets in rural areas, all of which are still relatively short of supplies as a result of the Covid 19 pandemic (KAVILANZ, 2022).

Even so, it is a time when the Federal Reserve Board is preparing to reduce the subsidy granted to the US economy during the recession, which is being gradually withdrawn, at the same time that the referred bank shows its enormous concern about the possibilities of growth in inflation, among other circumstances that can compromise the country’s financial recovery (CBS NEWS, 2021).

Rocha (2021) states that, to a large extent, such difficulties were potentiated in the United States by the denialism of then President Donald Trump regarding the dangerousness of the disease, in addition to the dissemination of fake news regarding matters related to Covid 19, among them, the guidelines regarding the use of hydroxychloroquine, the lack of incentive for preventive hygiene measures and the use of face protection masks, as well as the lack of massive incentive for social isolation and vaccination.

This way of dealing with the situation led the United States to the top of the list of countries with the highest rates of infected people and consequent deaths. Rocha (2021) reports that former President Trump’s view of the disease led him to withdraw the country from the United Nations Educational, Scientific and Cultural Organization (UNESCO) and the UN Human Rights Council, and consequent suppression of collaboration in investments provided for scientific research until then.

Under the pretext of questioning the authority of the World Health Organization (WHO), and accusing China of manufacturing and exporting the new coronavirus, in addition to pointing out the Chinese delay in alerting that body about the reality regarding the emerging health crisis, the former -President Trump lowered the usual investments in that WHO to 6.91%, among other measures that harmed multilateral relations (ROCHA, 2021).

Regarding the commitment of the supply chain, Attinasi et al. (2022) argue that “supply chain bottlenecks result from the interaction of several factors”, and list them: 1. Strong recovery in global demand for manufactured goods, which was not accompanied by an increase in the supply of goods; 2. Sectors largely affected by the lack of supply, including semiconductors, due to the growth in demand for electronic products and equipment, partially caused by social isolation and the needs of working from home for a large part of the population; 3. Logistics-related interruptions as a result of port congestion and container ship activities; of restrictive blocking measures in some Asian countries, which are important suppliers of different intermediate inputs.

Faced with this reality, upon assuming the US presidency, current President Joe Biden reformulated the country’s engagement in multilateral issues; promoted the immunization of 50% of the local population, that is, of the people who accepted the vaccination; announced the return of that country to the WHO, in addition to the elaboration/adoption of a plan to distribute 55 million vaccines around the world, allocating 75% of these to the most needy countries (ROCHA, 2021).

Regarding the service of national suppliers, it appears that among the sectors that suffered the most from the delay in production are 36% of small manufacturing, civil construction and different businesses, according to data tabulated between May 31 and June 6 2021, by the US company Census Small Business Pulse (ROCHA, 2021).

In turn, Helper and Soltas (2021) report that the impact caused by the interruption in the supply chain caused problems that persist in other segments, including the civil construction, automotive, clothing and essential items sectors.

With regard to the civil construction sector, the scarcity of wood for structure, wall panels and roofs still persists, hindering the progress of constructions. The price of wood rose by 19% between May 2020 and May 2021, despite falling later, according to a survey conducted by the National Association of Home Builders. Given the volatility of the sector, the alternatives found by the builders were to delay the start of new works (HELPER and SOLTAS, 2021).

The automotive sector, on the other hand, faces a sharp rise in prices for new, used and rented cars, greatly impacting the upturn in this segment. Faced with the Covid 19 pandemic, automakers canceled their usual orders for the acquisition of semiconductors because they believed in a drop in demand (HELPER and SOLTAS, 2021).

However, its difficulties increased a lot, as it is a component whose normal supply is already taking a long time, an aspect that was much worse when its production was sliced, when each part of its production phases was in charge of several companies. around the world (HELPER and SOLTAS, 2021).

Gerdeman (2022) explains that, in addition to the lack of inputs related to restrictions on manufacturing and shipping from suppliers, the automotive and electronics sectors were especially hit, as delivery times increased to 21 weeks by Malaysian suppliers, for example.

Among the other items necessary for the production of motor vehicles, there are steel, plastic and rubber, which are among the 30,000 parts necessary for the production of each vehicle unit, and it is also necessary to consider the logistics necessary to transport all the necessary parts from different parts of the country (HELPER and SOLTAS, 2021).

In turn, the apparel sector was affected as Chinese production of manufactured textiles, footwear and machinery dropped sharply in March 2020, compared to March 2019. Against this backdrop, the United States identified opportunities to import supplied textile products by India and Bangladesh, as well as footwear and machinery supplied by Vietnam (HEISE, 2020).

With regard to basic necessities, in the face of social isolation, at the beginning of the Covid 19 pandemic, the consumption of good quality toilet paper increased by 40% by the civilian population, in the face of social isolation and their permanence in House. Afraid of the lack of the article, North Americans “cleaned store shelves” (HELPER and SOLTAS, 2021).

Since it is an item whose demand is usually stable, the storage of large quantities of this product is hampered, as it is a very bulky item. Added to this fact is the issue related to the size of machinery, the volume of personnel and the size of properties suitable for new manufacturing facilities and the volume of pecuniary capital in record time, unfeasible in a short period of time that allowed to circumvent the impacts of the pandemic (HELPER and SOLTAS, 2021).

Among the solutions found by manufacturers are: producing rolls larger than the usual size; operate their machinery at the maximum possible capacity (92%); keep stocks for two to three weeks; reactivate any idle machinery; reduce the rest interval of your equipment; invest in their distribution processes, anticipating possible regional shortages (HELPER and SOLTAS, 2021).

LABOR SHORTAGE

According to the report by the consultancy Everstream, specialized in Artificial Intelligence, the demand for workers is expected to grow significantly in 2022, given the difficulties of organizations in different sectors in filling their jobs, especially for activities related to Logistics, which suffers from a lack of drivers for trucks and vans, among other opportunities (GERDEMAN, 2022).

Another one, among the phenomena caused by the Covid 19 pandemic, whose results impacted the economy in a comprehensive way, due to the loss of personnel, interruptions in the supply chain, the increase in the cost of living and the urgencies of the resumption of industrial processes, commercial and services, the lack of personnel to fill the open positions has allowed the pressure of workers for the increase in the offered salaries (GERDEMAN, 2022).

Even in the face of the current drop in unemployment insurance claims in the United States, which recorded levels below 250,000 claims in March 2020, experts estimate that companies are committed to maintaining their workforce, given the current difficulties by hand work (CBS NEWS, 2021).

One can mention, for example, Malaysia, which is one of the main suppliers of semiconductors in the world, which reduced the production of these components by 60%, given the need to adopt a third national blockade, given the recurrent outbreaks of the disease that reached local workers, causing the suspension of their industrial activities (GERDEMAN, 2022).

It is also worth mentioning the contamination of truck drivers by the Ômicron variant, as well as the work of countless people allocated in the different production areas, among them the packaging and transport of meat; the contagion of workers in warehouses, ports, retailers and stores, all had their work and performance impacted, facts reported by Jon Samson, executive director of the American Trucking Associations (McCAUSLAND, 2020).

In his testimony before the US Congress, Samson reported that before the pandemic, the industry, in general, already had 80,000 fewer drivers, but that this problem was greatly enhanced with the advent of Covid-19, since, the lack of professionals for loading and unloading goods impacted compliance with delivery deadlines.

Despite the evolution of the situation, entrepreneurs responsible for business in ports, warehouses, restaurants, supermarkets, restaurants and fast food still face instability in their supply, as many workers were affected by the new variant of the omicron, being temporarily disabled for normal work (McCAUSLAND, 2020).

In turn, entrepreneurs in the meat packaging industry are concerned about what has been dubbed the “vaccine mandate” that emerged with the Biden Government, which encourages adherence to vaccination in every way, to which many workers are refractory. If such a project is approved, businessmen fear a massive stampede of labor in this sector. In addition, problems with labor legislation would arise, because this industrial segment would be prevented from hiring new unvaccinated workers, impacting its productivity (McCAUSLAND, 2020).

MULTILATERALISM AND THE RETURN OF THE WORLD ECONOMY

According to an IMF analysis, the health crisis caused by Covid 19 caused a decline of 5.3% in trade in consumer goods in October 2020, an index that was below that estimated by the WHO, whose projection estimated 9.2%. It is recorded that the different countries promoted fiscal and monetary protection actions to internal organizations, adopting 133 protectionist measures by G20 component countries, of which 63% were to facilitate trade, and only 37% restrictive (ROCHA, 2021).

There are several factors to be considered for a more robust recovery of the world economy, despite the clear signs of this evolution. McCausland (2022) points out the risks of new variants of the Ômicron and possible peaks of cases as impeding factors of a more effective recovery. In addition, it reports the occurrence of abnormal weather patterns, in the face of rains and tornadoes in the middle of spring.

Regarding the omicron variant of COVID-19, Attinasi et al. (2022) share McCausland’s (2022) view, regarding an eventual “closure of factories and ports and as a result, they throw more uncertainties, especially in the short term. In particular, there could be setbacks in supply chains if China continues to adhere to a strict COVID-zero strategy.” The authors also report that the war in Ukraine constitutes yet another global concern for the optimal resumption of supply.

Given the need for companies to create more attractive job opportunities to attract new workers, it is estimated that from the second half of 2022 onwards, the normalization of the supply chain will take place in a more natural way. McCausland (2022) highlights that 4.5 million Americans spontaneously left their jobs in November 2021, certain of the existence of better offers and opportunities.

Attinasi et al. (2022) contradict McCausland’s (2022) predictions, suggesting that global supply problems will not normalize before the end of 2022, especially in the eurozone, which comprises the following countries: Germany, Austria, Belgium, Cyprus, Slovakia , Slovenia, Estonia, Finland, France, Ireland, Italy, Luxembourg, Malta, Netherlands, Portugal, Greece and Spain.

In the view of Gerdeman (2022) and Helper and Soltas (2021) the pandemic is already over, given the signs of a decline in the reflexes in the interruption of the supply chain, which are due, in part, to the fact that the ômicron variant is much less severe than the others.

The slow recovery in business shows records of new home sales rising to levels that exceed global sales in this segment over the past 14 years, while auto sales have surpassed the global sales total of the last 15 years. As for manufacturing items, accumulated stock levels reached 45 days, against 33 days at the present time, as a result of the impact of interruptions in the production chain (HELPER and SOLTAS, 2021).

In addition to the difficulties in maintaining inventories that meet the resumption of demand for consumer goods, organizations face the issue of the need to identify and hire labor, whose job vacancies reached the mark of 8.3 million in April of 2021 (HELPER and SOLTAS, 2021).

PREVENTIVE MEASURES ABOUT EVENTUAL SUPPLIES IN THE UNITED STATES

Among the lessons learned with the event of the Covid 19 pandemic, the resumption of some critical activities in the domestic production chain in the United States is considered, in addition to the search and definition of alternative suppliers, to avoid possible dependence on a single supplier for the different products (HEISE, 2020).

Gerdeman (2002) reports that, according to the consultancy Everstream Analytics, which specializes in Artificial Intelligence, points out in its Annual Supply Chain Report, there are five areas with which different countries should be concerned, some of which are related to the Covid-19 pandemic 19, reported here.

With regard to maritime cargo, which is a reliable, low-cost and extremely useful means of long-distance journeys, maritime transport is considered the backbone of global trade, and represents a concern, as demonstrated by the event of the pandemic of Covid 19. It can be mentioned, for example, that at the end of 2021, some ships were stopped for 30 days, waiting to dock in the ports of Long Beach and Los Angeles (GERDEMAN, 2022).

Regarding the increase in inventories, the dilemma arises in decisions about accumulating preventive stocks, an action that includes the purchase, storage and handling of items of interest, being an option that can cause high costs for their maintenance, or even that the stored items will spoil or become obsolete (GERDEMAN, 2022).

As for the sustainability factor, in the Everstream Consulting report, there are concerns from some countries such as Norway and Germany, for example, regarding environmental, social and governance issues, which imply legal and reputational risks (GERDEMAN, 2022).

These are aspects that consist of human rights violations related to the supply chain, and prohibitions on the sale of materials extracted, manufactured or produced in certain Chinese provinces, such as the province of Xinjiang, whose production, apparently, takes place from forced labour. It is noteworthy that companies that operate contrary to such prohibitions are prevented from marketing their products on North American soil (GERDEMAN, 2022).

With regard to global warming, international supplier companies, which are manufacturing producers, should pay attention to issues related to their local carbon emissions from both their companies and the original source of the raw materials used by their suppliers.

The world consumption of water should also be considered, since, according to projections prepared by the United Nations, 2/3 of the global population will suffer from water scarcity by 2025. General carelessness regarding water and its use will affect residences, industries and even logistical networks (GERDEMAN, 2022).

As an example, Gerdeman (2022) clarifies that in 2019 the larger ships used as container carriers traveled fully loaded through the Panama Canal. Another aspect lies in the water needs for agriculture, given that, given the imminent risk of water shortages, food production will be compromised.

PREVENTIVE MEASURES AGAINST SUPPLIES

Gerdeman (2022) mentions that there are improvements to be made regarding the elaboration of protective forecasts of the supply chain of the different industrial and commercial sectors. He clarifies that the consultancy Everstream Analytics has developed artificial intelligence tools for early detections that will allow problems similar to those that occurred during the Covid 19 pandemic to occur in possible future opportunities. This author reports that any preventive actions by Supply Chain Management are not limited to specific events.

Among the possible tools is the adoption of the blockchain system, which allows, among its various functionalities, the ability to monitor supply chains, records and certifications. Rodrigues and Yoshino (2021, p. 167) report that it is a technology for drawing up contracts between stakeholders without the involvement of third parties and without additional costs, whose data are traceable and irreversible, allowing “optimization of flows in supply chains ”. Blockchain is considered by experts as a “technology that solves problems such as security, oversight, transparency, privacy and trust of all involved”.

In turn, recent decisions by the Biden-Harris Government, such as the creation of a Supply Chain Interruptions Task Force (HELPER and SOLTAS, 2021).

With regard to short-term issues, the task force’s role will be to monitor and resolve aspects related to supplies in general, but with special attention to the segments of civil construction and electronic components, such as semiconductors, for example. In the long term, actions were proposed to strengthen the industrial base, with the aim of reducing solutions and responses to possible crises in local supply (HELPER and SOLTAS, 2021).

Regarding expenses related to risks inherent to supply chains, the proposal consists of investing in research, production, recycling for workers, as well as in local communities, promoting the reconstruction of sustainable manufacturing capacity in the country. The suggested investments were at least US$50 billion, to be considered and approved by the US Congress (HELPER and SOLTAS, 2021).

From an international perspective, the proposed Task Force suggests the strengthening of partnerships focused on the care inherent to the supply chain, according to the most convenient geopolitical strategies (HELPER and SOLTAS, 2021).

CONCLUSION

The scientific literature selected for the development of this study, combined with recent publications related to the Covid 19 pandemic, the sequential situations and governmental measures existing in the different media resources demonstrate the seriousness of the situations that have affected the whole of society in the last two years.

The changes that affected the local and global supply chain compromised the way people lived until then, ranging from the lack of various components for the industry, reaching the shelves of supermarkets and other types of shops, where even products are still lacking food for final consumers.

Such deficiencies are slowly and gradually being overcome after the sanitary measures implemented by the world health bodies, especially massive vaccination, allowing the return of a certain social normality.

However, the return to ideal levels still requires compensated efforts from governments and business in all the aforementioned aspects, as well as in terms of identifying and attracting labor in quantity and quality that meets the different sectors of the supply chain.

In response to the question proposed for the investigation of this study, which was: “how to promote the resumption of industry, commerce and services in the post-pandemic world?”, three actions considered fundamental for the return to normality are suggested, which are described below.

A first solution lies in the creation of a resilient supply chain, that is, one that provides good Supply Chain strategies, aiming to meet national/global demand in order to allow an effective restructuring of the sector, and to avoid possible new shortages in future crises.

As a second solution, it is believed that technological collaboration will be of great value, with the objective of creating high-performance tools/platforms, capable of managing Supply Chain processes, such as the use of the blockchain system.

Finally, and no less relevant, it is suggested to promote the training of individuals and teams, who are encouraged to achieve the objectives defined by the organizations.

REFERENCES

ATTINASI, Maria Grazia; DE SANTIS, Roberto A.; DI STEFANO, Claudia; GERINOVICS, Rinalds; TÓTH, Máté Barnabás. Supply chain bottlenecks in the euro area and the United States: where do we stand? ECB Economic Bulletin, Edição 2/2022. Disponível em: https://www.ecb.europa.eu//pub/economic-bulletin/focus/2022/html/ecb.ebbox202202_01~272e32f7f4.en.html; acesso em 06 jul 2022.

BARATA, Lourdes. As Epidemias e as Pandemias na História da Humanidade. Roteiro da memória. UL – Curso de Medicina da Universidade de Lisboa, News n. 99, março de 2020. Disponível em: https://www.medicina.ulisboa.pt/newsfmul-artigo/99/epidemias-e-pandemias-na-historia-da-humanidade#:~:text=A%20Gripe%20Espanhola%20é%20considerada,derrubados%20na%20Primeira%20Guerra%20Mundial; acesso em 06 jul 2022.

CAI, Min; LUO, Jianwen. Influence of COVID-19 on Manufacturing Industry and Corresponding Countermeasures from Supply Chain Perspective. Journal of Shanghai Jiaotong University (Science), 2020, vol. 25, n. 4, p. 409-416, 02 ago 2020. Disponível em: https://doi.org/10.1007/s12204-020-2206-z; acesso em 11 jul 2022.

CBS NEWS. U.S. economy slowed amid headwinds from COVID-19 and supply-chain woes. CBS NEWS, 28 out 2021. Disponível em: https://www.cbsnews.com/news/economic-growth-2-percent-q3-united-states/; acesso 06 jul 2022.

FERNANDES, Sandra; SIMÃO, Lucínia. Os conceitos e a evolução do multilateralismo: o nexo reflexão-ação. Imprensa da Universidade de Coimbra, 07 nov 2020. Disponível em: https://eg.uc.pt/bitstream/10316/96355/1/Os%20conceitos%20e%20a%20evolucao%20do%20multilateralismo.pdf; acesso em 01 ago 2022.

FONSECA JR, Gelson. Multilateralismo e Regionalismo. Academia, 2019. Disponível em: https://www.academia.edu/38663085/MULTILATERALISMO_E_REGIONALISMO?bulkDownload=thisPaper-topRelated-sameAuthor-citingThis-citedByThis-secondOrderCitations&from=cover_page; acesso em 06 jul 2022.

FUNDACE – Fundação para Pesquisa e Desenvolvimento da Administração Contabilidade e Economia. Qual é a diferença entre Logística e Supply Chain? FUNDACE, 07 mar 2019. Disponível em: https://blog.fundace.org.br/supplychain/#:~:text=O%20supply%20chain%20management%20envolve,reversa%20e%20redução%20de%20custos; acesso em 02 ago 2022.

GERDEMAN, Julie. Globalization: Understanding the “new normal”, supply chain risks in 2022 and beyond, DLH Delivered, Março, 2022. Disponível em: https://www.dhl.com/global-en/delivered/globalization/supply-chain-risks-in-2022.html; acesso em 06 jul 2022.

HEISE, Sebastian. How Did China’s COVID-19 Shutdown Affect U.S. Supply Chains? Federal Reserve Bank of New York Liberty Street Economics, 12 maio 2020. Disponível em: https://libertystreeteconomics.newyorkfed.org/2020/05/how-did-chinas-covid-19-shutdown-affect-us-supply-chains/; acesso em 05 jul 2022.

HELPER, Susan; SOLTAS, Helper. Why the Pandemic Has Disrupted Supply Chain? The White House, 17 jun 2021. Disponível em: https://www.whitehouse.gov/cea/written-materials/2021/06/17/why-the-pandemic-has-disrupted-supply-chains/; acesso em 06 jul 2022.

KAVILANZ, Parija. Nos EUA, até lojas de conveniência têm tido dificuldade de reabastecimento. CNN Brasil, 06 fev 2022. Disponível em: https://www.cnnbrasil.com.br/business/nos-eua-ate-lojas-de-conveniencia-tem-tido-dificuldade-de-reabastecimento/; acesso em 06 jul 2022.

LIMA JÚNIOR, Idoneu Mitrano; FONSECA, Celso Suckow da; RODRIGUES, Alba Regina Pereira; MELLO, José André Villas Boas. Riscos, Complexidade e Incertezas na Cadeia de Suprimentos: uma revisão sistemática de literatura. P2P & INOVAÇÃO, Rio de Janeiro, vol. 7, n. 2, p.277-294, 15 Mar 2021. DOI: https://doi.org/10.21721/p2p.2021v7n2.p277-294; acesso em 06 jul 2022.

McCAUSLAND, Phil. Here’s why store shelves are empty again in parts of the U.S. NBC NEWS, 12 jan 2022. Disponível em: https://www.nbcnews.com/business/business-news/why-store-shelves-are-empty-omicron-bad-weather-hurt-supply-chain-rcna11859; acesso em 06 jul 2022.

NEOWAY. Cadeia de Suprimentos: o que é, as etapas e como fazer a sua gestão. NEOWAY, 24 mar 2021. Disponível em: https://blog.neoway.com.br/cadeia-de-suprimentos/; acesso em 01 ago 2022.

PESSOA, Josimara de Oliveira; MOREIRA, Otacílio José; FERREIRA, Carla Guimarães; MURTA, Aurélio Lamare Soares; MURTA, Maria da Penha Araújo. Gestão de risco na cadeia de suprimentos: um estudo de caso. Revista UNIABEU, vol. 10, n. 26, p. 175-190, set/dez 2017. Disponível em: https://revista.uniabeu.edu.br/index.php/RU/article/view/2819; acesso em 06 jul 2022.

ROCHA, Aline Afonso Silva da. O papel do multilateralismo em tempos pandêmicos. Relações Exteriores, 05 ago 2021. Disponível em: https://relacoesexteriores.com.br/multilateralismo-tempos-pandemicos/; acesso em 05 jul 2022.

RODRIGUES, Tamires Marques de Souza; YOSHINO, Rui Tadashi. Blockchain aplicado a Supply Chain. Brazilian Journal of Development, Curitiba, v.7, n.3, p. 28166-28178. 20 mar 2021. Disponível em: https://brazilianjournals.com/ojs/index.php/BRJD/article/view/26685/21138; acesso em 17 ago 2022.

SILVA, Mygre Lopes da; SILVA, Rodrigo Abbade da. Economia brasileira pré, durante e pós-pandemia do covid-19: impactos e reflexões. UFSM – Observatório Socioeconômico da Covid-19, 19 jun 2020. Disponível em: https://www.ufsm.br/app/uploads/sites/820/2020/06/Textos-para-Discuss%C3%A3o-07-Economia-Brasileira-Pr%C3%A9-Durante-e-P%C3%B3s-Pandemia.pdf; acesso em 11 jul 2022.

TIRONI, Luís Fernando. Regulamentação Técnica, Acordos Comerciais e Multilateralismo. IPEA – Instituto de Pesquisa Econômica Aplicada, Rio de Janeiro, 2650, abril, 2021. Disponível em: http://dx.doi.org/10.38116/td2650; acesso em 02 ago 2022.

YOSHIDA, André Yugo. A Importância Da Atuação Do Pcp Em Tempos De Pandemia. Universidade do Estado do Amazonas. Manaus, 2020. Disponível em: http://177.66.14.82/bitstream/riuea/3327/1/A%20importância%20da%20atuação%20do%20PCP%20em%20tempos%20de%20pandemia.pdf; acesso em 05 jul 2022.

[1] Graduated in Business Administration and Post Graduated in Controllership.

Sent: August, 2022.

Approved: August, 2022.