ORIGINAL ARTICLE

BENTES, Maria Heloisa Cavalcante [1], SOUZA, Karoline Santiago de [2], SILVA, Wilson Luís Rodrigues da [3], ROBERTO, José Carlos Alves [4], ALMEIDA, Victor da Silva [5]

BENTES, Maria Heloisa Cavalcante. Et al. Proposal for a new production method for a better product at Polysul Indústria e Comércio de Embalagens LTDA. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year. 07, Ed. 06, Vol. 03, p. 20-38. June 2022. ISSN: 2448-0959, Access link: https://www.nucleodoconhecimento.com.br/business-administration/production-method

ABSTRACT

This article was created with the aim of outlining new production strategies for products sold in the packaging market. For this, in the course of the research, an organizational diagnosis was elaborated, which pointed to the production sector as the most critical of the Polysul company. Through this consideration, a study was prepared based on quality tools for product improvement. The guiding question of the study was: what strategies can be implemented in the Polysul company in order to provide improvements in the product? The general objective was to propose the implementation of new production methods to improve the product offered by the company Polysul. The methodology that guided this study was exploratory and descriptive analysis; as for the means, the study was documentary, bibliographic and field. The need for improvement in the production strategies of the Polysul company was perceived and, for that, it was suggested the application of Kanban quality tools in the packaging production process. As a result, it was proposed: implement improvements through reverse logistics; 5S implementation; packaging Kanban restructuring; flexible plastic packaging plan, through the Failure Modes and Effects Analysis (FMEA) tool; and implement PDCA cycles, whose improvement actions will have results from brainstorming sessions in meetings with the teams. Finally, it is expected that through the insertion of the exposed intervention actions, the company will manage and organize the process of production of made-up packaging, thus improving the workflow and the quality of the product.

Keywords: Quality Tool, Polysul, Product.

1. INTRODUCTION

This article proposes a case study on the company Polysul Indústria e Comércio de Embalagens Ltda (fictitious name). Through field observation, based on the analysis of the company in question, an interventional work was proposed, based on the application of quality tools in the production process of the Polysul company to increase the quality of the product offered. However, the article also analyzed how the external environment can directly influence the sales of these products. Therefore, through the research, the aim is to demonstrate how the company can have its products better known in the market through the quality of the packages sold (BALLOU, 2014). The general objective was to propose the implementation of new production methods to improve the product offered by the company Polysul. According to the proposed objective, it can be seen that Kanban must be applied in order to control daily production flows of packaging, which will add greater quality to the products.

The problem question of this study intends to address the following problem: what strategies can be implemented in the Polysul company in order to provide improvements in the product? In the field research, the organizational structure of the delimited company was analyzed to understand how the entire production process is carried out: bags, sacks, bags (of different colors and sizes), plastic films and reels. Based on this observation, intervention actions were established to improve the products. The work outlined a scientific methodology for research and, thus, starts from some methodological assumptions. The approach is qualitative and the nature is descriptive, exploratory and explanatory. For the analysis of the chosen case, it starts with data collection and analysis techniques specific to the methods adopted (LIBÓRIO; TERRA, 2015).

The specific objectives of the research are: to evaluate how the internal functioning of the production of products in the company Polysul occurs; study how the Kanban tool can be implemented in the production sector of the company Polysul; and demonstrate how the Kanban tool implementation can improve the packaging production flow. Therefore, quality tools will be of paramount importance for the standardization of product production. This standardization, in turn, in order to generate good results, will be based on training applied to the company’s employees. In addition, the interventional actions adopted will be essential for the incorporation of changes, aiming, in this way, at an improvement for everyone in the organization.

2. THEORETICAL FOUNDATION

For Vergara (2017, p. 36), “the theoretical foundation should be divided into sections and subsections, which vary in function depending on the approach to the theme and method”. Therefore, it must present the studies previously carried out on the topic or problem generated by the study. What can be seen is that the basis of a scientific text is the works that are researched and explored, that is, this means that a summary of several works must be made and that the theoretical positions must not only be reported in a summarized way, as they must be analyzed and confronted (LIBORIO; TERRA, 2015).

2.1 CONCEPT AND DEFINITION OF REVERSE LOGISTICS

There are many resources in the commercial area in relation to logistics, however, the instruments that are currently used in reverse logistics are essential, that is, it can also use interface resources in conjunction with the area of the logistics system. According to Martins (2015, p. 84), reverse logistics is “the quality of a product as the set of elements and characteristics that meet the needs of consumers x the environment”. The first link that triggers reverse logistics is the commercial area, that is, it is worked together with the marketing area, which, in turn, captures society’s latent desire in relation to the consumer’s already explicit environment and takes advantage of the resources available to present solutions and establish a permanent two-way relationship with the consumer (BALLOU, 2014).

According to Martins, (2015, p. 97), “reverse logistics is a tool that aims to direct post-consumer packaging and materials”. For recycling or for obtaining energy, what is discarded is destined for local dumps and landfills, however, this type of disposal generates a negative environmental impact. In addition, waste that is not destined for dumps and landfills is taken to cooperatives and recycling operators. It was noticed that reverse logistics is based on the prevention of aspects related to the environment, that is, it is concerned with the conscious disposal of materials used and consumed in our daily lives (BALLOU, 2014). Those who start from the perspective of reverse logistics have concerns, such as the quality of the raw material, the manufacture of the material used, the disposal of the material used, the awareness of society in relation to this material, preventive actions against environmental pollution and with the sanitation of practices that generate a negative impact on the environment in which we live.

2.2 QUALITY CONCEPT

Quality is a subjective concept and is directly related to what each person can perceive. Several factors influence the quality, such as: services provided, structural models, business culture, the customer’s primary/secondary/tertiary and quaternary needs. For Drucker (2013, p. 69), “the company is created and managed by people, it is not managed by forces, as economic forces set the limits to what an administration can do”. The nomenclature quality has the meaning aligned with the needs and perceptions of a certain group, aiming to present positive results for this group (MARSHALL, 2016). During the research, it was observed that the primary factors of quality must be applied in the daily business, especially so that the customer can express his satisfaction with a quality product offered to him.

2.3 THE QUALITY PROCESS

Even in first-rate companies, the reputable ones in the market, poor quality costs a lot. According to Schonberger, (2020, p. 98): “when work progresses through all processes in an integrated manner, the apparatus to control the process is not satisfactory.” When operations assume responsibility for quality, it becomes clearer and easy to follow.

The word team means any set of people and has the purpose and purposes consistent with the service provided to the customer, therefore, team means a group of people related and integrated through the work flow, because, by definition, this comprises a chain of customers (MAXIMIANO, 2015). The main task is to provide the customer, with that product, well-being.

In view of the above, in relation to the customer chain, it can be considered that it is about the way in which people and their work resources are grouped most of the time and, regardless of the function, a common objective is pursued (SCHONBERGER, 2020). In the criteria of the quality process, it is interesting to perceive the possibility of carrying out a detailed work.

2.4 TOOL 5S

The 5S tool aims to develop and improve business aspects, according to Marshall (2016, p. 58): “[…] aspects such as: standardization, cleanliness and organization”. In companies, the 5S Program is implemented based on strategic planning. It corresponds to the junction of the number “5” with the letter “S”. It adds five words that begin with S, according to Laugeni (2013, p. 81): “sense of use, organization, cleanliness, standardization, discipline”. It can be seen that the main objective of applying the 5s tool is to encompass all employees so that their personal and professional skills are strengthened, such as: sense of discipline and sense of organization, that is, developing these skills provides these employees with a greater safety and professional quality (MARSHALL, 2016).

2.5 KANBAN TOOL

The Kanban tool aims to create a system capable of managing and organizing projects that aim to control workflows developed effectively and efficiently. For Chiavenato (2014, p. 87): “the processes that are related to Kanban tools, it has the purpose of controlling daily flows, which correspond to quality products”.

The Kanban tool, at first, had its origin in a production and logistics system, but over the years it has been incorporated into numerous sectors of a company, even the IT area, which develops software (PALADINI, 2014). As stated by Chiavenato (2014, p. 89): “the concept of Kanban can be defined by the following items: define, separate, determine, stipulate and interact, so that operational processes are executed efficiently and effectively”. It was noticed that the Kanban tool can be efficient in sectors that apply continuous production tasks. It corresponds to a board where each column is related to a certain performance status and each card is related to a specific task.

2.6 TOOL FAILURE MODES AND EFFECTS ANALYSIS (FMEA)

The FMEA tool aims to analyze the failure and its effects. It consists of a method that adds reliability to products and processes, that is, it seeks to operate in a way that does not fail. According to Abranches (2014), there are four key elements in this tool: “Effect, Cause and Detection”. FMEA is one of the quality tools that has its applicability in the engineering area, such as: production and product. This technique is used during the product creation process or in the project phases that demand care in the operation and maintenance of a particular product, avoiding failures in the process and, later, in the product (ABRANCHES, 2014). According to Maximiano (2015), FMEA is distinguished in design FMEA, process FMEA, systems FMEA and service FMEA. The FMEA aims to detect and outline systematic resolutions on failures caused by causes and effects, that is, non-conformities. It can be used in conjunction with other tools, such as: Pareto Chart, 5w2H, Kanban, among others.

2.7 PDCA TOOL

The PDCA cycle is the most used management method for achieving total quality with a view to customer satisfaction. According to Campos (2014, p. 303): “all process management consists of establishing improvements and standards set up in the organization, which serve as a reference for management”. It was developed in 1930 by Walter Shewhart at Bell Laboratories in the USA. PDCA (plan, do, check, act) is of English origin, which means: plan, do, check and act –, that is, we seek to act correctly (CAMPOS, 2014).

One of the best known quality models, the PDCA, was applied at work, as it is a simple and effective model to be followed by the company. With this aspect, the quality management is presented in the form of nomenclatures to the actions that must be taken. According to Abranches (2014, p. 303): “all process management consists of establishing improvements and standards set up in the organization, which serve as a reference for management”. According to this aspect highlighted by the author, quality management is presented in the form of nomenclatures, such as: PDCA. The meaning of the PDCA nomenclature, according to Paladini (2014), means: Plan (P), Execute (D), Check (C), Act – Act correctly (A), and the planning will have to be standard within an organization, because big changes result in a big improvement, however, protocols must be followed.

3. MATERIALS AND METHODS

The materials and methods are of paramount relevance for an academic work, according to Furasté (2013, p. 18): “materials and methods mean tools that led the study to reach the paths traced at the beginning of an academic planning”. It is important to emphasize that the materials and methods take into account: the nature, the object of study and the techniques of data collection and analysis.

3.1 METHODOLOGICAL PROCEDURES

The present work is a documentary, bibliographic and field study, which chooses a private company located in the city of Manaus as a research field. During the research, data collection and document analysis of the data provided by the organization itself were carried out. According to Libório and Terra (2015, p. 22): “the methodological procedures used in a work is a study of the ways that use the instruments used to carry out research”. From what was studied, within the documentary and bibliographic approach, the collection and reading of materials were based on books, articles, magazines and websites.

3.1.1 AS TO NATURE

Scientific research can be classified in two ways: basic and applied. In the case of the research in question, it is an applied study. The approach is qualitative. Marconi and Lakatos (2014, p. 47) exemplify the two means as: “qualitative research observes the relationship between the world and the subject, in addition to that translated into numbers […] with the central objective of the research is to understand the explanation of the phenomenon”. The nature of the research, in turn, fits as exploratory. Data exploration will be based on observations, records, analyses, classifications and interpretations of data referring to Polysul Indústria e Comércio de Embalagens Ltda. (fictitious name).

3.1.2 AS TO THE PURPOSES

The research proposes an exploratory and descriptive analysis, since it was necessary to explore and describe the data obtained in the field. According to Vergara (2014, p. 48): “the types of research can be described by two basic criteria: in terms of ends and in terms of means”. The purpose of the research is to respond in a meaningful way to the question that generated the problem that was elaborated during the field research. Therefore, this research has as problematic the following question: How to provide improvements in the product through the introduction of new productive strategies?

3.1.3 AS TO THE MEANS

It can be seen that the means are essential to achieve the objectives outlined at the beginning of the research. According to Marconi and Lakatos, (2014, p. 26): “the means of a research can be varied, through analytical and synthetic techniques, for the construction of knowledge”. The research was carried out in three stages:

- First stage: the identification and purpose of the organization, corporate name, address, company history, mission, vision, values, organizational policies and the organization’s objectives and goals are highlighted;

- Second stage: the organizational structure includes the products produced, the size of the company and its characteristics in terms of physical facilities, the characteristics of the staff and the organizational chart of the organization;

- Third stage: the analysis of the internal environment is highlighted, identifying the strengths, weaknesses, points to improve in the predefined areas and graphics of critical areas and their analysis, and it is proposed to analyze the external environment, that is, its opportunities and threats, stakeholders, main customers, main competitive differential in the market where the company operates and main suppliers.

3.1.4 COMPANY CHARACTERISTICS

The company Polysul was created in 1993. Little by little, the company acquired more machinery and hired qualified labor and, at the same time, there was an expansion of its customer base. Due to the growing demand of the market, there was a need to acquire a new installation that would support the investment of a modern and diversified park of machines, causing, in this way, an increase in the diversity of products and in the profitability of the company, still serving all the quality requirements demanded by the market and by the NBR ISO 9001:2008 standard, certification achieved by the company in 2011.

With a recognized brand of products, today, the company supplies the entire state of Amazonas, Roraima, Acre and part of the state of Pará, having its own distribution fleet. The company produces bags, sacks, bags (of different colors and sizes), plastic films and reels. In the manufacture of products, it uses virgin raw material in its process, acquired from approved suppliers, that is, the materials are qualified in terms of quality requirements, delivery time, freight and price.

4. RESULTS AND DISCUSSIONS

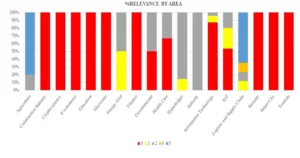

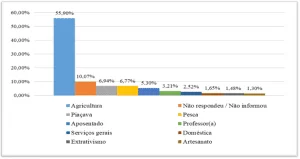

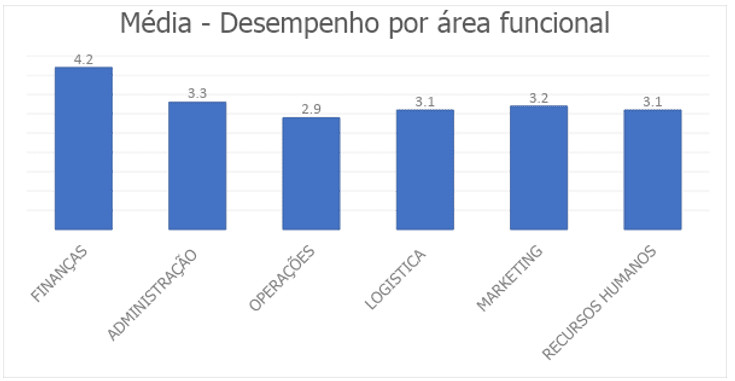

To demonstrate the results, the study was based on an Organizational Diagnosis. The data he evidenced showed that the company in question had fundamental points in each functional area. From the analysis of the functional areas, the Diagnosis showed the critical points that needed to be improved in the Polysul company. These data can be seen in Graph 1.

Graph 1 – Analysis of Critical Areas of the Internal Environment

At this stage, the way in which the functional areas were performed was evaluated. The environmental analysis activities that were carried out in the company were considered so that it was possible to help it achieve its goals effectively and efficiently. As evidenced by Oliveira (2013, p. 14): “the administration will be better able to establish, reaffirm or modify its organizational goal”. By formulating new organizational strategies aimed at production, the administration will be able to set new objectives, being able to even diversify its line of business so that the products meet the needs of the consumer market. During the research, it was observed that the company had the best performance in the areas: finance, administration and marketing. The operation was considered more critical, as shown in Table 1.

Table 1 – Functional Area of the most critical department of the company Polysul

| FUNCTIONAL AREA | ASSESSMENT LEVEL OR DEGREE | |||||

| OPERATIONS | Very strong point 5 | Strong point 4 | Midpoint 3 | Weak point 2 | Very weak point 1 | |

| 1 | It is seen that the location is accessible and the movement of the area is good | x | ||||

| 2 | The division of shelves and specifications by branch takes place | x | ||||

| 3 | Agility in the internal supply of materials is considered | x | ||||

| 4 | It appears that there is equipment for handling and internal locomotion of products | x | ||||

| 5 | Availability of material for production is guaranteed | x | ||||

| 6 | It is noticed in the company that the obsolescence control is carried out | x | ||||

| 7 | It is found that the space in the institution is large, airy and light. | x | ||||

| 8 | It is considered that the parking is adequate for the Employees | x | ||||

| 9 | Level analysis is observed to visualize and eliminate excesses | x | ||||

| 10 | It is noted that the Work Safety items – PPE’s are adequate | x | ||||

| TOTAL (Ʃ) | 0 | 4 | 21 | 4 | 0 | |

| AVERAGE PER GRADE (PER COLUMN) | 0 | 0,4 | 2,1 | 0,4 | 0 | |

| AREA PERFORMANCE (Ʃ) TOTAL | 2,9 | |||||

Source: Prepared by the authors, 2022.

According to Table 01, it was observed that fundamental items to the operational area in the company Polysul Indústria e Comércio de Embalagens Ltda needed improvement. This area is of great importance for the manufacture of the products sold, because, in addition to a product of excellence, it is necessary that aspects such as space, employees and supplies are aligned for a good development. In this way, the problem question was elaborated as follows: what strategies can be implemented in the Polysul company in order to provide improvements in the product?

4.1 ACTION PLANNING

Companies in the packaging segment experience rapid growth, while others stagnate or fail. Organizations that seize opportunities stand out, while those that act too late stagnate. Efficient companies, therefore, are always planning or executing their projects.

Table 2 – Interventive Actions

| Interventive Actions | Chronology | Duration | Cost | |

| 01 | Implement improvements through Reverse Logistics | June/2021 | 15 days | R$ 3.000,00 |

| 02 | 5S implementation | July/2021 | 15 days | R$ 2.550,00 |

| 03 | Restructuring of packaging Kanban | August/2021 | 10 days | R$ 3.200,00 |

| 04 | Flexible plastic packaging plan, using the Failure Modes and Effects Analysis (FMEA) tool | September/2021 | 5 days | R$ 2.342,00 |

| 05 | Implement PDCA cycles, whose improvement actions will have results from brainstorming sessions in meetings with teams | October/2021 | 5 days | R$ 2.900,00 |

Source: Prepared by the authors, 2022.

In summary, it was noticed that there are no strictly individual plans, as there is always teamwork that involves collaboration and understanding of everyone, that is, the work of a planning team has its advantages, however, it faces several challenges that multiply depending on the proposed planning and the involvement of employees. Action planning has the purpose of executing the elaborated plan, being necessary so that each action can be practiced for the improvement of the company, aiming at the achievement of the outlined objectives.

4.1.1 IMPLEMENTATION OF IMPROVEMENTS THROUGH REVERSE LOGISTICS

The action plan aims to guide the management of companies so that they can improve their activities, that is, through this it is possible to propose a schedule with relevant actions to achieve more efficiency for each activity.

Table 3 – Implement improvements through Reverse Logistics

| IMPLEMENTATION OF IMPROVEMENTS THROUGH REVERSE LOGISTICS | |

| What? | Schedule the application of training to employees on Reverse Logistics, taking into account new raw materials; |

| Why? | Because, in addition to better assimilation of content, training becomes effective; |

| When? | During the weekend between October 18th and 19th |

| Who? | To all employees of the company Polysul, including: assistants and leaders; |

| Where? | Polysul Indústria e Comércio de Embalagens Ltda; |

| How? | Using external labor. |

| How much? | R $3.000,00. |

Source: Prepared by the authors, 2022

During the research, it was noticed the importance of reverse logistics in the process of implementing improvements in the company Polysul. Training was carried out and it demonstrated to employees the importance of the theme: “Reverse Logistics”. This training was intended for employees to understand the importance of recycling the material produced in the Polysul company, as the focus was on raising awareness in the implementation of an improvement program. The main objective with this strategy is the reduction of environmental pollution generated by the company.

4.1.2 5S TOOL IMPLEMENTATION

For an improvement in the performance of the Polysul company’s departments, it will be necessary for employees to understand the benefits of the 5S tool, enabling the organization of sectors, and taking into account factors such as: cleanliness, standardization, discipline and use of materials that could be discarded.

Table 4 – Implement the 5s tool

| 5S TOOL IMPLEMENTATION | |

| What? | Implement the 5s tool through training; |

| Why? | Improve the scope of work; |

| When? | First week of August; |

| Who? | Apply to all employees of Polysul company departments; |

| Where? | Polysul Indústria e Comércio de Embalagens Ltda; |

| How? | Through a lecture that can clarify the importance of 5s; |

| How much? | R $2.250,00. |

Source: Prepared by the authors, 2022.

The 5S Program was proposed as a strategic plan based on training all employees, with the aim of improving all departments of the Polysul company. This program corresponds to the junction of the number “5” with the letter “S” associated with five words that begin with S: – Sense of utilization; Sense of organization; Sense of cleanliness; Sense of standardization; and sense of discipline. The main objective with the implementation of 5S was to achieve greater business quality and, in this way, it was possible, with the incorporation of the tool, to improve several aspects, such as organization, cleanliness and standardization, however, the research had as focus on promoting continuous improvement for incessant human and professional growth.

4.1.3 IMPLEMENTATION OF PACKAGING KANBAN RESTRUCTURING

As the company works with large-scale production of materials, such as bags, sacks, bags (of different colors and sizes), plastic films and reels, which are mostly discarded and not used for other purposes, the Kanban tool has the purpose of standardizing the production service without the waste of raw material.

Table 5 – Implement the Packaging Kanban Restructuring.

| PACKAGING KANBAN IMPLEMENTATION | |

| What? | Train employees for a better organization in the production flow; |

| Why? | In order to standardize the service. |

| When? | In the last week of August |

| Who? | Apply to employees of the production department of the company Polysul |

| Where? | Industry and Commerce of packaging Polysul Ltda; |

| How? | From meetings with employees of the company Polysul, to produce better products and provide better services; |

| How much? | R $3. 200,00. |

Source: Prepared by the authors, 2022

It was proposed a training with employees of the company Polysul. The objective was for them to have a broad knowledge of the points that were essential to improve the production system, namely: visual system, cards and limitation of work in progress. The purpose of training employees was for them to start using the Kanban tool, as it adds quality to the visual system of work management. Allows each task to be performed from a predefined workflow

4.1.4 IMPLEMENTATION OF THE FLEXIBLE PLASTIC PACKAGING PLAN, THROUGH THE TOOL FAILURE MODES AND EFFECTS ANALYSIS (FMEA)

The applicability of FMEA is intended to promote improvement in the production area, with the main objective of strengthening product engineering. This tool is used during the product creation process or in the project phases that demand care in the operation.

Table 6 – Implement the Failure Modes and Effects Analysis (FMEA) tool.

| IMPLEMENTATION OF THE FAILURE MODES AND EFFECTS ANALYSIS (FMEA) TOOL | |

| What? | Apply the moment method of packaging production through training |

| Why? | Aiming to improve the product sold in the market |

| When? | In the last week of September |

| Who? | To the employees of the production department. |

| Where? | Industry and Commerce of packaging Polysul Ltda; |

| How? | Through an internal analysis. |

| How much? | R $2.342,00. |

Source: Prepared by the authors, 2022

The intention in implementing the FMEA tool is to standardize the Polysul company’s production mode. The product creation process is the basis that the company has to offer its customers a quality in what is available. It is important to emphasize the intention to apply the FMEA. It is about the awareness of the care taken with the process of creating a particular product, as this factor makes all the difference when it reaches the final customer, bringing more reliability and security to the future acquisition.

4.1.5 IMPLEMENTATION OF PDCA CYCLES, WHOSE IMPROVEMENT ACTIONS WILL HAVE RESULTS OF BRAINSTORMING SESSIONS IN MEETINGS WITH TEAMS

The PDCA tool, when applied, allows the planning of new production models that will be recognized by employees, that is, this tool manages the quality of the product offered in the packaging market.

Table 7 – Implementation of PDCA cycles, whose improvement actions will result from brainstorming sessions in meetings with teams

| IMPLEMENTATION OF PDCA CYCLES, WHOSE IMPROVEMENT ACTIONS WILL HAVE RESULTS OF BRAINSTORMING SESSIONS IN MEETINGS WITH TEAMS | |

| What? | Plan the production of products using the PDCA tool; |

| Why? | So that there is a better quality in the products that are produced; |

| When? | In the first week of September; |

| Who? | Apply to all employees of Polysul company departments; |

| Where? | Industry and Commerce of packaging Polysul Ltda; |

| How? | Showing the importance of quality management |

| How much? | R $2.900,00. |

Source: Prepared by the authors, 2022.

With planning, the management process takes place, and this aspect was proposed to the production department in the form of nomenclatures, explaining the meaning and importance of each PDCA nomenclature: Plan, Execute, Check and Act.

4.2. IMPROVEMENTS IN THE PACKAGING PRODUCTION PROCESS THROUGH THE KANBAN TOOL

The Kanban tool must be implemented with the aim of creating a system capable of managing and organizing projects and controlling the workflows developed effectively and efficiently (CHIAVENATO, 2014). These processes are related to the purpose of controlling daily flows, as they allow the creation of quality products. Kanban is a tactic used to reduce costs with processes, such as: material, time, personnel and leftover material. This tool arises to define, determine and interact with operational processes. It was noticed that the implementation of the Kanban tool is well developed in sectors that apply continuous production tasks. Generates a board where each column relates to a certain performance status and each card relates to a specific task.

Table 6 – PDCA – Implement Kanban Quality Tools

| STEPS OF CONTINUOUS IMPROVEMENT | ||

| PDCA | PHASES | OBJECTIVE |

| P | 1st Identification of the problem | Lack of processes in packaging production |

| 2nd Analysis of the Phenomenon | Failure to meet the best quality requirements in the product | |

| 3rd Process Analysis | Lack of product planning | |

| 4th Develop action plans to achieve the goals | Implement an action plan for the production of packaging | |

| D | 5th Execution | Align with employees working in the sector time for product production |

| C | 6th Check | Check if production planning is being respected |

| A | 7th Adequacy | Implement a routine in the production of products |

| 8th Standardization | Implement a standard in product production | |

Source: Prepared by the authors, 2022.

The study was intended to propose the implementation of the Kanban tool in the company studied throughout the research. It was noticed that for this change in the packaging production process to be viable, it would be necessary for the company in question to understand the improvement processes, as it contributes in an impactful way in relation to the quality of the product that circulates in the market.

5. CONCLUSION

With regard to the business world, there are strategies, programs and plans for them to be able to operate in their segment. The product production process has changed a lot, since the search for cost-benefit improvement has increased, as everything is thought and analyzed according to profitability x market, that is, a quality product is now one of the focuses in companies, tactics have to be ready to win and keep your customers, because there is no longer a customer loss that goes unnoticed.

Regarding the general and specific objectives defined in the present study, it is concluded that they were successfully achieved through research and analysis, since the work in question analyzed the functional performance of the respective areas and, through the results obtained, it was possible identify the critical area that needed to be improved and, based on that, intervention actions were designed to incorporate improvements in the packaging production process.

The guiding question was also elaborated: what strategies can be implemented in the company Polysul in order to provide improvements in the product? Based on the guiding question, it was proposed to carry out training with the employees of the Polysul company and, with that, it was proposed to implement a new production flow in order to add an improvement to the system, especially in some aspects, such as: visual system, cards, process progress, action plan for packaging production, non-waste of raw material, product production time and the importance of product quality. Therefore, the results of this study showed that the actions represented benefits when quality tools such as: Kanban and PDCA were used. They can solve problems not only for the Polysul company, but also for other companies, in the same segment or not, that have the same critical area.

REFERENCES

ABRANCHES, F. S. Gestão de Logística, Distribuição e Trade Marketing. 4ª ed. Rio de Janeiro: FGV Editora, 2014.

BALLOU, R. H. Logística Empresarial: Transportes, administração de materiais e distribuição física. Tradução: Hugo T. Y. Yoshizaki. 5ª ed São Paulo: Editora Atlas, 2014.

CAMPOS, E. A. da. Gestão estratégica: da empresa que temos para a empresa que queremos. 4ª ed. São Paulo: Saraiva, 2014.

CHIAVENATO, I.; SAPIRO, A. Planejamento estratégico. 4ª ed. Rio de Janeiro: Elsevier, 2014.

DRUCKER, P. Desafios Gerenciais para o século. São Paulo: Editora Pioneira, 2013.

FREITAS, A., PORTUGAL, L. da. S. Estudos de transporte e Logística na Amazônia. Manaus: Novo Tempo, 2016.

FURASTÉ, P. A. Normas e Técnicas para o Trabalho Científico. 16ª ed. Porto Alegre: s.n, 2013.

GIL, A. C. Como elaborar projetos de pesquisa. 5ª ed. São Paulo: Atlas, 2013.

LAUGENI, F. Administração da Produção. 3ª ed. São Paulo: Saraiva, 2013.

LIBÓRIO, D.; TERRA, L. Metodologia científica. 1ª ed. São Paulo: Rede Internacional da Universidade Laureate, 2015.

MARCONI, M. de. A.; LAKATOS, E. V. Fundamentos de metodologia científica. 8ª ed. ver. e ampl. São Paulo: Atlas, 2014.

MARSHALL, J. I. et al. Gestão da Qualidade. 9ª ed. Rio de Janeiro: Editora FGV, 2016.

MARTINS, P., CAIXETA-FILHO, C. Administração de materiais e recursos patrimoniais. São Paulo: Saraiva, 2015.

MAXIMIANO, A. C. A. Introdução à administração. 9ª ed. São Paulo: Atlas, 2015.

PALADINI, E. P. Gestão da qualidade: teoria e prática. 3ª ed. 9ª reimp. São Paulo: Atlas, 2014.

SCHONBERGER, R. J. Construindo uma corrente de clientes. 4ª ed. São Paulo: Pioneira, 2020.

VERGARA, S. C. Projetos e Pesquisa em Administração. 12ª ed. São Paulo: Atlas, 2014.

[1] Graduate of the Administration course.

[2] Graduate of the Administration course.

[3] Graduate of the Administration course.

[4] Advisor. Master in Production Engineering. Specialist in Business Logistics. Graduated in Business Administration with Emphasis in Marketing.

[5] Co-advisor. Master in Process Engineering. Postgraduate student in Institutional Neuro Psychopedagogy. Specialist in Strategic HR Management. Graduated in Administration and Pedagogy.

Sent: May, 2022.

Approved: June, 2022.