BRITO, Alexandra Antonia Freitas de Brito [1]

BRITO, Alexandra Antonia Freitas de Brito. The fourth Industrial Revolution and the prospects for Brazil. Multidisciplinary Core scientific journal of knowledge. 07 Edition. 02 year, vol. 02. pp 91-96, October 2017. ISSN: 0959-2448

Summary

In the increasingly competitive world in search of new technologies, the industry grows at an unprecedented speed. Unlike all the revolutions passed, these new technologies are increasingly agile and flexible and are changing not only the industry, but also the society, politics, the public sector and the economy. It is in this context that is inserted into the fourth industrial revolution, this new concept encompasses the main technological innovations: Automation, control and information technology, from Cyber-physical Systems, Internet of things and Internet services. This article, through bibliographical research, discusses the concept of revolution, 4.0 objectives, its applications, the impacts and the projection of this new revolution in Brazil.

Keywords: Fourth Industry Revolution, technological innovation, Internet of things.

1. Introduction

The first Industrial Revolution had your home in England, in the mid-18th century, in the period from 1760 to 1840. Occurred through the advent of the steam engine, used in the fabric industry, there was the replacement of factory production crafts works, which significantly increased production. Another important factor was the use of this technology in the means of transport: ships and trains. During this period there was the discovery of Telegraph, by means of wires and submarine cables. The first industrial revolution fostered social and economic changes.

The second Industrial Revolution began in the United States, after France, Germany, Italy, Belgium and the Netherlands. Occurred in the mid-19th century, between the years 1850 to 1950. The main events occurred through scientific and technological progress, the discovery and exploitation of new energy sources such as oil, through the burning of the use in the combustion engine, hydroelectric plants, nuclear energy, among other discoveries revolutionized the industrial production, the emergence of new chemicals and the substitution of iron for steel.

Another important factor was the industrial production in series and the Division of labor that has reduced the production cost per unit, through the Assembly lines, conveyor belts where circled parts of the product to be mounted, in order to streamline the process. The auto industry Ford, installed in the United States, was the first to produce through this production process, this production method was known as Fordism, led to the emergence of large industries and the generation of large economic concentrations.

The third Industry revolution, l or the informational revolution, also occurred in the United States (which became the great economic power of this period) began in the mid-20th century, to the present. Corresponds to the process of innovation in the field of information technology and its applications in the fields of production and consumption. The great achievements of this period are the development of so-called fine chemicals, biotechnology, space, climbing to robotics, genetics, among other important advances. Has as main feature the use of advanced technologies in the industrial production system.

And finally the fourth industrial revolution or the revolution 4.0, arose from the beginning of the 21st century, in the year of 2011, after the Federal Government of Germany enter the revolution 4.0 as a strategic initiative with the aim of repositioning the front-of-the-art technologies and competitiveness for its industries (KAGERMANN, WAHLSTER, & HELBIG, 2013).

The fourth Industrial Revolution or 4.0 Industry is targeting for "Cyber-physical production", in which smart sensors tell machines how they should be processed; the processes must govern themselves in a decentralised modular system.

This article seeks to relate the main approaches about the revolution 4.0, because this new revolution is at the beginning and a lot of changes must happen. As for the Brazilian scenario a brief explanation about how are the national front of this new revolution and addresses the main goals of the national plan on the internet of things, released on the last day of October 3 by the Federal Government.

2. Key concepts about the fourth Industrial Revolution or revolution 4.0

The fourth Industrial Revolution is the stage at which the machinery and equipment industries, based on Cyber-physical systems, begin to make decisions when on, off or when accelerating or reducing production in the manufacturing environment. Already the Americans prefer the term Manufacture advanced (GOMES, 2014).

The Cyber-physical production syste[2]ms where the sensors inform the machines as they are to be processed, the processes must govern themselves in a decentralised modular system. Embedded systems communicating wirelessly, either directly as via a "cloud" on the Internet-the Internet of things (Internet Thing or IoT) – for once revolutionize production. The centralized systems of control rigid yield place to decentralized intelligence with machine communication (M2M) machine on the factory floor. This is the vision of industry 4.0 the fourth Industrial Revolution (DONOVAN, 2014).

4.0 industry seeks to describe the combination of several technological trends (artificial intelligence, sophisticated sensors and the internet of things) that attach the virtual world and the physical world, that have emerged in recent years and hoped for that, combined, transform fully understanding of the industry sector currently (MARTINS, 2016).

The revolution 4.0 is the Union of the so-called internet of things with rapid automation and design a new scenario in the factories around the world. 4.0 industry, or advanced manufacture should revolutionize the Assembly lines and generate innovative and customized products in the near future (SIEMENS, 2016)

The fourth revolution is the fusion of these technologies and the interaction with the physical, digital and biological dimensions that make the current phenomenon different from all the previous ones. Emerging technologies and innovation in a wide scale have spread faster and wider than in past movements (SCHWAB, maio2017).

The industrial revolution will be triggered by the internet, which includes communication between human beings, as well as with the machines in a Cyber-physical System (CPS) in large networks (BRETEL, 2014).

4.0 industry for BAUR and WEE, 2015 is seen as the next phase of manufacture applied to scan processes, driven by four disruption technologies: i) data growth by computational capacity and connectivity; II) the ability of the data analysis for market intelligence sectors; III) new ways to interact in the workplace between man and machine; IV) and finally the digital commands transfer improvement to the physical environment (extracted from SIMPOI, ANAIS2017).

It is observed that the common points between the authors about the concept of the fourth revolution based on high technologies in the field of automation, as siber systems-physicists, internet "cloud", internet of things and smart plants, i.e. It encompasses innovations current technological moment applied to manufacturing processes in the interaction of humans and the machine in order to increase your productivity and stay competitive in the market.

3. Main technologies applied to the model of the fourth Industrial Revolution

There are several technological trends that encompass this new industrial revolution in order to improve efficiency in the production, services, the improvement of people's lives, in the field of health, transportation and other sectors of the economy, then the main technologies.

Cyber-physical Systems 3.1 or Cyber-Physical Systems (CPS)

Enables integration between computer science and physical processes (LEE, 2008). Is the result of the technological evolution of computers, sensors and communication technologies to evolve towards greater agility, processing capacity and increasingly affordable prices have allowed the conjugation of your effectively and in real-time ( BOHUSLAVA et al, 2017). According to LEE (2008), the economic and social potential of these systems is much higher than what has been done and major investments are being made throughout the world to develop the technology.

3.2 Internet "cloud"

Is the supply of computing services across servers, storage, databases, network, software, analysis, among others, all over the Internet.

3.3 Internet of things

That term became known "the Internet of things (loT)" after a survey in the area of radio frequency identification (RFID), British guitarist Kevin Ashton, in 1999, explaining that computers could be linked together in networks and work independently and intelligently, without human intervention. To Haller (2010), defines IoT as a world in which physical objects are perfectly integrated in the data network and where physical objects can become active participants in business processes.

3.4 Smart Plants

Machinery and inputs "talk" over the industrial processes that occur relatively autonomous and integrated, GOMES (Feb .2017).

Equipment located in different industry units can also exchange information in real time about purchases and stocks, for example, creating a logistics optimization and establishing greater integration between the component parts of the production chain. GARCIA, (Feb, 2017).

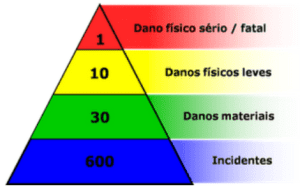

The following TABLE 01, shows the first steps of the fourth industrial revolution:

4. Impacts of the fourth Industrial Revolution

The fourth industrial revolution arrive with changes of the world in the coming years. On the one hand the new technologies that facilitate the life of the population, improvement in desemenho of industries, advances that make it possible to carry out the work in the area of medicine as technological capabilities that enable high precision during surgery for example, nanotechnology, among others. On the other hand there is the social issues, employment and the economy will be allocated in this new scenario?

The main changes expected in the industry in general are: changes in customers ' expectations; Products smarter and more productive; New forms of collaboration and partnerships; and the transformation of the operational model and conversion into digital model (SCHWAB, 2016).

For SCHWAB (2016) the major concern of this new scenario will be the issue of inequality, because innovation and disruption should affect our standard of living and welfare of the people, both positive as negative, being difficult to predict how much could affect, since people are the time consuming and producing memos.

The impact of industry 4.0 is very comprehensive, it affects the entire chain: producers, manufacturers, suppliers and workers. Education will have to intensify the preparation of more talents, equipped with skills and competences needed conjuntoas in this new moment (AKITIS, 2015).

Many companies already seeking to integrate the product specific needs and preferences of each customer through customization of the product by consumers, being a variable in the process of manufacture, and smart companies will be able to take the customization of each client, adapting to the preferences (SEN, 08/Oct. 2017).

5. The fourth revolution and the challenges for Brazil

In Brazil there are few competitive sectors on a global scale, integrated processes that ensure the customized production and innovative products of the revolution 4.0. The Brazil still needs to walk a lot in these two senses (ZANCUL .2016).

Some Brazilian industries came out in front, with projects that can be considered 4.0, as in the case of companies: Ambev (multinational), that in 2015, adopted a system of automation for better control of the process of beer cooling and reduce the temperature variations, with consequent reduction in energy cost and Volkswagen Brazil, where all projects are created from a digital model. The products are simulated in 3D environment, which speeds up the process, ensures flexibility, optimizes production time and further opens highly qualified jobs (Studio ABC, 2016).

On the last day of October 3, was launched by the Federal Government, the national plan for the Internet of things, whose goal is to provide more intelligence in the provision of public and private services, through empowerment of people, innovation and entrepreneurship.

Final Considerations

The fourth industrial revolution is in your initial stage and its technologies have changed everything we have ever seen at the time. For developed countries like the United States and Germany, it is already a reality, both by the Government and the industries, although there is a great project for aggregating efforts and generate critical mass of labor market and qualification " says Zancul.

As was discussed at the world economic forum, the Internet with industrial focus will turn many industries, including manufacturing, oil and gas, agriculture, mining, transport and health.

In Brazil, slowly the new tecnologidas 4.0 industry are inserted, some Brazilian companies are already in the new phase as are the cases cited AMBEV and Volkswagen. As for the federal Government, was launched the national plan of the internet of things, later we can see how it will be applied the technology to the improvement of the quality of public service.

The most troubling of the fourth industrial revolution, observed during the survey was with respect to unemployment, because the reduction or exclusion of some activities that do not involve technical knowledge. On the other hand there will be more demand for highly skilled professionals with expertise in technological, biological, chemical area, among others. One of the solutions would be the Government invest in technical schools, and better quality education.

References

ARKTIS. 4.0 INDUSTRY, the fourth REVOLUTION INDUSTRIAL.dez, 2015. Available in: > http://arktis.com.br/a-quarta-revolucao-da-industria/> Access in October 13, 2017.

ANG, J. H.; GOH, C.; Li, y. Smart design for ships in the smart product through-life and industry 4.0 environment. 2016 IEEE Congress on Evolutionary Computation (CEC), p. 5301-5308, 2016.

ACCENTURE TECHNOLOGY (Org.). Internet of Things: industrial Reimagine the Possibilities … 2016. Available in: <http: www.accenture.com/us-en/technology/technologylabs/pages/insight-industrial-internet-of-things.aspx="">.</http:> Access in: 02 mar. 2016.

BRETTEL, Malte et al. How virtualization, decentralization and network building change the manufacturing landscape: An Industry Perspective 4.0. International Journal of Mechanical, Industrial, Science and Engineering, v. 8, n. 1, p. 37-44, 2014

CNI (Brazil). 4.0 INDUSTRY CHALLENGES in BRAZIL. 2016. Available in: <http: www.pedbrasil.org.br/ped/artigos/079f8ba3e7e5281b.0="" no="" brasil.pdf="">.</http:> Access in: 13 Oct. 2016.

DONOVAN, John. NEWTON C. BRAGA INSTITUTE. 4.0 industry – what is it? (ART1350). July 2014. http://www.mouser.com/empoweringinnovation/smartercities/NewtonCBraga accessed: October 13, 2017.

DREHER, THE. The Smart Factory of the Future-Part 1. Belden News. Available: http://www.belden.com/blog/industrialethernet/The-Smart-Factory-of-theFuture-Part1.cfm. Access: June 2, 2016.

MDIC. Advanced manufacturing, 29 NOV. 2016. Available in: > http://www.mdic.gov.br/inovacao-in/fomento-a-inovacao/manufatura-avancada > Access in October 13, 2017.

MALIK, MAFALDA. 4.0 industry. 5 Aug 2016. Available in: > http://flowtech.pt/pt/blog/impacto-industria-4-0-manufatura/> Access in: 13 of October 2017.

SORRY, RODOLFO. The third revolution is the process of computerization of the means of production and industrial technologies. Brazil school, available at:<http: brasilescola.uol.com.br/geografia/terceira-revolucao-industrial.htm="">accessed: October 13, 2017.</http:>

HSM MAGAZINE. Started the fourth Industrial Revolution, 3 may, 20017. Available in:

<http: www.revistahsm.com.br/inovacao/comecou-4a-revolucao-industrial/="">Accessed: October 13, 2017.</http:>

ABC Studio, SIMENS. How will the industry 4.0 Professional? Published on 3 June 2016.

SIMPOI, EIDRICH, KISETSUPROJECT, CRISTINA. The Competitive Impact on brazilian Industry with the aplicaçãi of the industry 4.0 concepts 2017.

SCHWAB, K. The Fourth Industrial Revolution. 1st Edition, World Economic Forum. Crown Business: New York. ISBN: 9781524758869, 2016.

WOLLSCHLAEGER, M.; SAUTER, T.; JASPERRNEIT, J. The Future of Communication: Industrial Automation Networks in the Era of the Internet of Things and Industry 4.0. IEEE Industrial Electronics Magazine, v. 11, p. 17-27, 2016.

[1] Economist Graduated in economics from the Federal University of Amazonas-UFAM. Regional development expert by UFAM. Public servant of the Superintendency of the Manaus free trade zone, as an economist.

[2] The concept of Cyber-physical Systems (CPS) was first defined by Dr. James Truchard, CEO of National Instruments in 2006, based on the virtual representation of a manufacturing process in software (DONOVAN, 2014).