ORIGINAL ARTICLE

LIMA, Willis Correia de [1]

LIMA, Willis Correia de. The Brazilian Air Force on the wings of work safety. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year 05, Ed. 12, Vol. 11, pp. 92-118. December 2020. ISSN: 2448-0959, Access link: https://www.nucleodoconhecimento.com.br/education/air-force

SUMMARY

Work accidents are caused (unconsciously or consciously) at all times and the Brazilian Air Force (FAB) is no different, causing damage, loss of time, absences, pain and death! Even the Force already adopting a preventive conduct in these events that are a reality that the Internal Commissions for Accident Prevention (CIPA) work are in the Military Organizations (OM) Brazil. The discussion of how work safety is presented within the Scope of the Christmas Aeronautics Garrison (GUARNAE-NT) is the main objective of this article. It was embraced in the Regulatory Standards (NR) of the Ministry of Labor and Employment (MTE) in what encompasses work safety, as well as in the standards of the Air Force and the Annual Report on Safety at Work 2019 of the Garrison. It was found that accidents and reports occurred in the work environments and that the reflection on the safety of work is necessary at all times.

Keywords: Work accident, adverse event, prevention, awareness.

1. INTRODUCTION

This article presents in the military field a reality that civil society also faces, the prevention of work accidents – an adverse event, and that in the barracks this prevention has been worked daily.

Through the Observatory of Safety and Health at Work – an important tool of the Public Ministry of Labor (MPT), it is identified that in Brazil in 2017, at least one worker was fatally injured in an accident at work every four and a half hours. In that year, 675,025 Occupational Accident Communications (CAT) were recorded and 2,351 deaths were reported. (BRASIL, 2018)

Revista CIPA [2] (2019) reports that in view of this situation, Brazil ranks fourth in number of deaths from work accidents, with China (1st), United States (2nd) and Russia (3rd). (CIPA MAGAZINE, 2019)

The Brazilian Air Force for some time has prioritized prevention conduct, a fact ratified by the author, who in 1994 – 26 years ago, in the then Aeronautical Material Park of Recife (PE), held the Course of Prevention of Occupational Accidents for members of the Internal Commission for Accident Prevention.

All deserve respect and consideration, because they are important links of a current (process) to achieve the general objective of the Military Organization and the FAB, because “we are the only living and intelligent resources of a corporation, being able to deal with all other resources”. (IBF, 2018)

Training is the biggest investment that is made for prevention! To this end, the volunteering of CIPA members (in the accident prevention activity) is reconciled, culminating in training and personnel development for theoretical and practical improvement.

With this, it is possible to identify the difficulties presented and promote the implementation of work safety in the reality of the FAB.

1.1 JUSTIFICATION

Prevention is better than cure! Popular jargon well known in the preventionist medium. Every day work accidents are caused – consciously or unconsciously, and generate pain and suffering, damage to property, temporary or permanent removal and even death.

Within the Brazilian Air Force is no different, because we deal with human beings, and as much as they are trained and qualified, the adverse event can be provoked.

It is with the purpose of promoting a reflection on the safety of work in the barracks, where men and women expose themselves to the intrinsic risks of each military activity, which aims at this contemplation, to promote awareness in the effective of the Garrison of The Christmas Air Force, in which the prevention of work accidents is alluded to.

To this end, it was subjectively based on the foundation of Bisso (1990) and Tavares (1996), as well as, in the legislation relevant to the theme presented to us in Regulatory Standard No. 5 (NR 5), Preparation Standard (NOPREP/ADM/14) and Standard Standard of Action (NPA_CIPA/Ala 10/701), where it is questioned: How does fab have been adhering to work safety within GUARNAE-NT?

To discuss how work safety is presented within GUARNAE-NT is the main objective of this article, which will be defended through the identification of the difficulties presented within the scope of the garrison and the submission of implementations of realistic work safety conducts by GUARNAE-NT as specific objectives.

2. BRIEF HISTORY OF THE CREATION OF THE BRAZILIAN AIR FORCE

Piloted by a Brazilian, Alberto Santos Dumont (1873-1932), pilot and creator of the machine – the 14 BIS, performing this feat in Paris (France), in the Field of Bagatelle on November 12, 1906, flying a machine (apparatus) heavier than air. (NOVA ESCOLA, 2006).

More than thirty-five years after the first flight, on January 20, 1941, the Ministry of Aeronautics was created, by Decree-Law No. 2,961, and its military arm, The National Air Forces – which was the first designation of the current Brazilian Air Force. The means that made up the airships of the Navy and the Army were gathered, in addition to the Department of Civil Aeronautics (DAC) that belonged to the Ministry of Traffic and Public Works, beginning the construction of Brazilian air power and all the transformations that aviation has provided to the Nation, Filho (2012) reminds us that

Over the next few years, the Air Force expanded its operations in areas such as the defense of the sovereignty of Brazilian airspace, air traffic control, the promotion of the national industry, search and rescue missions, the space project, science and technology, the investigation and prevention of aeronautical accidents, and national integration, through the construction of runways and flights of transport aircraft. (FILHO, 2012)

3. THE PREVENTION OF AERONAUTICAL ACCIDENTS

Created in 1971 through Decree-Law No. 69,565, the Center for Investigation and Prevention of Aeronautical Accidents (CENIPA) central organ of the Aeronautical Accident Investigation and Prevention System (SIPAER), which provided the emergence of a new philosophy to be disseminated in the country, where the word inquiry was replaced and investigations began to be carried out with the sole objective of promoting the “prevention of aeronautical accidents” , in accordance with international standards.

CENIPA’s mission of the Air Force Command (COMAER) is “To promote the prevention of aeronautical accidents, preserving human and material resources, aiming at the progress of Brazilian aviation”.

Therefore, the accumulation of knowledge acquired with other Flight Safety organizations around the world, consolidated with the experience accumulated over the years, which resulted in the improvement of the doctrine of operational safety in Brazil and the establishment of research bases in this field: the trinomial “man, the middle and the machine”, a pillar of the modern SIPAER philosophy. (BRASIL, 2017)

Consequently, the prevention of aeronautical accidents had its concern focused on the correct procedures and conducts in the daily treatment, as well as contributed to the prevention of work accidents.

4. BRIEF HISTORY OF THE CHRISTMAS AERONAUTICS GARRISON

In the middle of World War II, the Natal Air Base Center was created by the Brazilian government on March 2, 1942 and its activation took place on August 7. In November of the same year, they began to live in the same airfield, in “Parnamirim Field”, two Air Bases. The Brazilian, located in the Western Sector of the airfield, and the American in the East Sector. Known as The Victory Trampoline, so-called for being a mandatory crossing point for allied aircraft that were destined for the African Theatre of Operations.

At the end of the War, The Natal Air Base began to occupy the facilities of the American Base. The buildings of the so-called West Base had, over time, the most different purposes, such as: Military Instruction Center and Military Pilot Training Center (CFPM), activated on March 6, 1970, with the deactivation of the Natal Air Base (BANT).

As stated in the Official Gazette: The Christmas Aeronautics Garrison – GUARNAE-NT,

created according to Ordinance No. 192/GM2, of April 29, 1954, with headquarters in the municipality of Parnamirim, State of Rio Grande do Norte, constituted by the following military organizations and fractions:

(a) Ward 10 and subordinate units;

b) Hell Barrier Launch Center – CLBI;

c) Natal Airspace Control Detachment -DTCEA-NT;

d) Natal Health Squad – ES-NT;

e) Christmas Support Group – GAP-NT;

f) Tactical and Specialized Instruction Group – GITE;

g) Christmas Aeronautics Prefecture – PANT; And

h) Third Squadron of the First Communications and Control Group – 3rd/1st GCC. (BRASIL, 2018)

5. BACKGROUND ON SAFETY AT WORK

Walking side by side were the safety procedures – whether they were flying or on the floor of the workshops, which could not be neglected because it is a risk activity[3] [4]! However, since the emergence of aviation, the initial concern has been with flight safety, but over time the safety of work has been incorporated into this new universe – that of labor prevention, and has come to be seen with the relevance of its action to avoid accidents, because it presented (and presents) the care inherent to its field of action.

Thus, the safety of work took a leap in the anticipation of adverse events, which was much asked, reported by Bisso (1990) who comes and presents us the works of personalities as

George Bauer (1556) who published a book on the main diseases and accidents of which the miners and smelters of gold and silver – asthma of the miners were victims; For Celso (1567) he elaborated a monograph on the relationship between work and diseases typical of workers – mercury poisoning; the Italian physician Bernardino Ramazzini (1700) – Father of Occupational Medicine – who edited the book Disease of Workers (De Morbis Artificum Diatriba). (BISSO, 1990, p. 15 – 16)

These protagonists ratified the way in which the understanding of the perception of risks focused on work activities and the care that should be provided in the prevention of accidents was sought.

Tavares (1996), is another to contribute to the clarifications that throughout the work experience professionals were concerned (and concerned) about the unhealthy conditions of workers, bringing us that since the 1930s some studied the Fundamentals of Prevention and Control of Losses, as mentioned in their work through engineers H. W. Heinrich and Frank E. Bird Jr.

Tavares (1996), informs that Heinrich

presented in his work Industrial Accident Prevention – edited in 1931, his analyses through the proportion of 1:29:300 and being understood as a disabling injury for 29 minor injuries and 300 accidents without injuries. Proportion that originated the Pyramid of Heinrich. (TAVARES, 1996, p. 9)

Right after, Frank E. Bird Jr. updates the relationship elaborated by Heinrich, in his book Damage Control, which “during the period from 1959 to 1966 was analyzed more than 90,000 accidents at Luckens Steel (steel maker) presenting the most up-to-date ratio of 1:100:500 – a crippling injury for 100 minor injuries and 500 accidents with damage to property.” (TAVARES, 1996, p. 9)

However, Bird continued to expand his studies and after analyzing the accidents

occurred in 297 companies, from 21 different industrial groups, reached the great number of 1,750,000 workers and more than 3 billion hours of exposure in this period, which resulted in another new proportion 1:10:30:600, where a serious or disabling injury appears for 10 minor injuries to 30 accidents with property damage and 600 incidents. (TAVARES, 1996, p. 9)

Therefore, it is verified how much has been done and knowledge in the area of occupational safety for accident prevention is important.

5.1 THE INTERNAL COMMISSION FOR THE PREVENTION OF ACCIDENTS IN BRAZIL

Piza (1997, p. 24) brings us, for some time, the knowledge that the Internal Commission for Accident Prevention (CIPA) was created after a recommendation from the International Labor Organization (ILO) to governments and industries to implement people concerned about the safety conditions involved in labor activities.

To this end, Decree-Law No. 7,036 of November 10, 1944 was created, which made CIPA official in Brazil, and which initially did not have a defined title. Its mandatory installation of the referenced commissions in the workplace only took effect on June 19, 1945, by instruction of the then National Department of Labor through Ordinance No. 229.

6. THE SAFETY OF WORK IN THE FAB

The Federal Constitution (1988) and the Consolidation of Labor Laws (1943) deal, in a basic way, on the safety and health of workers in Brazil.

In the Statute of the Military (1980), paragraph 2 of Art. 14 presents us with the definition of Discipline:

it is the strict observance and full compliance of the laws, regulations, norms and provisions that underpin the military body and coordinate its functioning, regular and harmonic, resulting in the perfect fulfillment of duty on the part of each and every one of the components of this organism. (BRASIL, 1980, our griffin)

Later, in Art. 27 portrays the essential manifestations of military value through its “technical-professional improvement” (item VI), complemented by Art. 28 that brings military ethics to “comply with and enforce the laws, regulations, instructions and orders of the competent authorities” (item IV). (BRASIL, 1980)

For training, courses and internships within the COMAER, an Aeronautical Command Instruction (ICA 205-42/2011) was prepared for the “General Safety Procedures Applicable to Training, Courses and Internships”, therefore, it is verified that compliance with safety standards also rests with us. (BRASIL, 2011)

Basically occupational safety and health at FAB is presented by safety links through the Internal Commissions for Accident Prevention distributed in the Military Organizations of the Air Force by the immensity of the country.

To this end, CIPA aims to “prevent accidents and diseases resulting from work, in order to make permanent ly compatible work with the preservation of life and the promotion of workers’ health”, according to item 5.1 of NR 5. (BRASIL, 1999a)

It is endorsed under the Preparation Command (COMPREP) through the Preparation Standard (ADM/14_2019 – Prevention of Occupational Accidents) which aims to “establish basic guidelines for the planning and execution of Occupational Safety activities, through the Internal Commission for Accident Prevention in the Organization (CIPA).”

The FAB emphasizes the important theme addressed here, in addition to the aforementioned norm(s), through other specific publications – in the area of prevention of work accidents, which are used in COMPREP, in which GUARNAE-NT is operationally subordinated, as well as legislation of other commands[5].

This relevance is unique by the course offered by:

1) Occupational Safety Course (CST)[6]– aims to train professionals to work more safely, preserving individual and collective health by reducing the risks inherent to the production process of a OM. (BRASIL, 2015)

Therefore, CIPA’s performance should be

in the preventive spirit, which will always guide its action, attentive so that this vision permeates all areas of the Organization in which it is inserted, stimulating the suggestion of preventive measures considered necessary, the dissemination and observance of occupational safety and medicine standards. (BRASIL, 2019ª)

For this, in the Military Organizations present three distinct situations for each type of victimized element (military, civil public servant or outsourced professional) that will have the support according to its own legislation:

a) military – suffers accident in service according to Decree No. 57,272, of November 6, 1965 and the Medical Expertise follows according to Ordinance No. 616/GM3 of May 13, 1980;

b) Civil Public servant – about accident in service or professional illness, according to Law No. 8,112/90, Law No. 8,270/91 and Ordinance No. 1,675 of October 6, 2006 (MPOG);

c) professionals of service providers – suffer accidents at work and are subject to occupational or occupational diseases, according to the contained in the CLT, Decree – Law No. 5,452, of May 1, 1943, and in the Social Security Legislation.

6.1 SAFETY OF WORK IN GUARNAE-NT

In the FAB’s OM, the laws pertaining to the prevention of accidents at work used in daily life are based on regulatory standards, in particular NR 5, which deals with the Internal Commission for Accident Prevention, NOPREP/ADM/14/2019 aimed at the prevention of work accidents in COMPREP’s OM and the Standard Standards of Action, in particular the NPA_CIPA/Ward 10/701/2019, GUARNAE-NT, which discusses the operation of the Internal Commission for Accident Prevention of Ward 10.

It was not possible to specify the date of creation of CIPA in the Garrison, but it is believed that it occurred on April 1, 1998 by the Command Instruction (IC 49/A1).

Thus, CIPA is a tool of direct advice of the commander of the Garrison with regard to the prevention of work accidents, and consists of approximately[7] 91 military (officers and graduates) from various sectors, currently having as president a colonel of the board of officers engineers (QOENG).

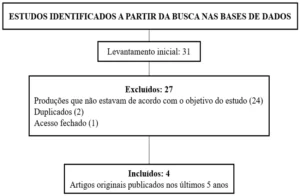

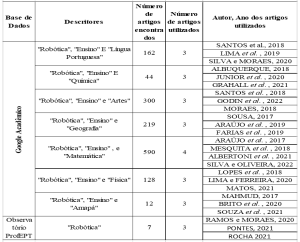

7. METHODOLOGY

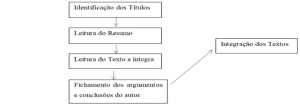

The object of study of this article is the result of discussions and an experience in the CIPA of GUARNAE-NT for more than 20 (twenty) years, teaching classes on “Occupational Safety and Training (NR 5, NR 6 and NR 35)”, conducting “Safety Surveys”, elaborating “Risk Maps”, collaborating in the organization of the Internal Week for Prevention of Occupational Accidents (SIPAT) and lecture on “prevention of accidents with animals that are , risk perception, prevention of accidents at work at height and pre-hospital care.”

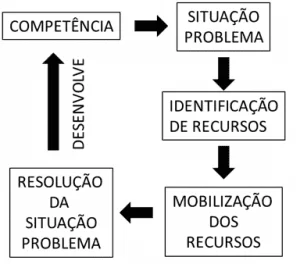

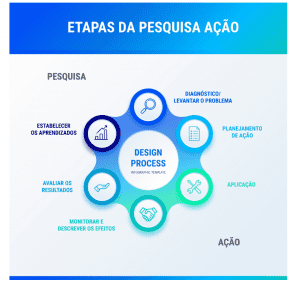

For this, the work presented was of an action research nature where Severino (2007, p. 120) “proposes to the group of subjects involved changes that lead to an improvement of the analyzed practices”, it is also based, in the diagnosis of what was experienced and discussed over this past period, in which we sought the theoretical basis on an important subject in the studies of Bisso (1990), Tavares (1996), Regulatory Standard No. 5 (NR 5), NOPREP/ADM/14/2019, NPA_CIPA/Ala 10/701/2019 and the 2019 Annual Report on Work Safety of GUARNAE-NT.

8. RESULTS AND DISCUSSION

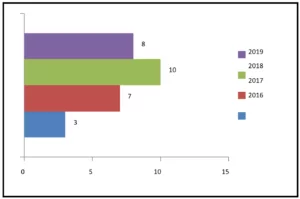

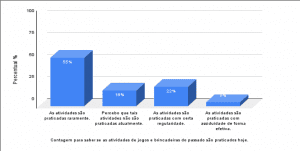

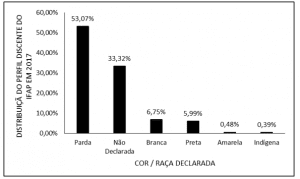

The considerations on item IV – Statistics and Conclusion are presented here, of the Annual Report on Occupational Safety 2019 produced by CIPA of Ward 10, which found that in that year were recorded 26 (twenty-six) adverse events, of which 14 (fourteen) Occupational Accidents and 12 (twelve) Incidents recorded, 1 (one) related to a third-party company – service provision and risk[8] reports (RR) that gave 51 (fifty-one) reports delivered , of which 2 (two) were employees of contracted companies (outsourced).

Adverse Events

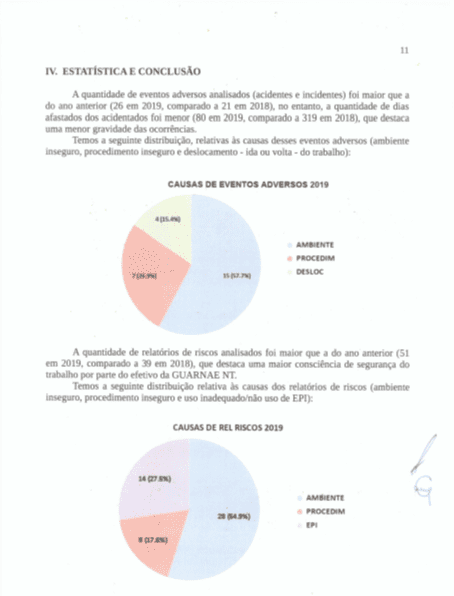

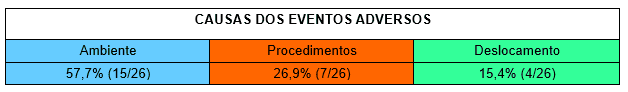

After analyzing the adverse events, the three latent causes highlighted among the events occurred were consumption:

1) Work environment (workshop floor)

2) Procedures in activities

3) Commuting home-work-home (path accident)[9]

Thus, it is questioned that more than half of the number of accidents occurred in the work environment, making up 57.7% of the total occurred (15/26) due to disorganized place and with slippery and/or damaged floor, reduced space, improper installations that can generate fire principle, material wear, little or no lighting and etc. Second, there are errors in procedures that were more than a quarter of events (7/26) having presented lack of knowledge and non-compliance with safety standards and conducts, misuse of tools, lack of use of EPIs and attention in the performance of activities and so on, and finally, with 4/26 (four of twenty-six) occurrences of travel accidents, and computed 29 (twenty-nine) days of “Withdrawal from all activities[10]” and 51 (fifty-one) days of “Total leave[11]”, as shown in Chart 1.

Table 1

Risk Reports

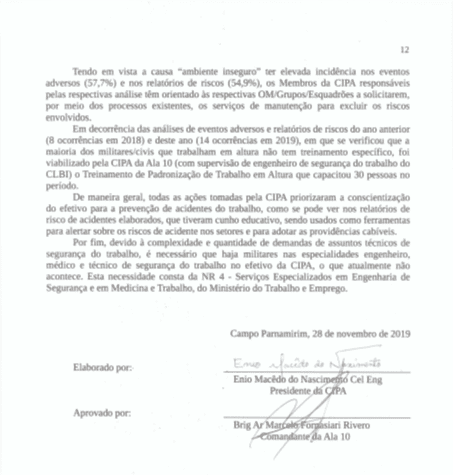

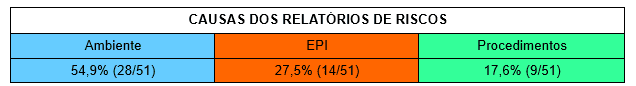

After analyzing the Risk Reports, it was concluded that three were the most important reports:

1) Work environment (workshop floor)

2) Lack of use of EPIs

3) Procedures in activities

The work environment or the workshop floor presented an incidence of more than 50% (fifty) of the Risk Reports due to being the propitious place for maintenance activities. Such situations observed are part of a clear perception of risks on the part of the staff, where disorganization, slippery flooring, damaged flooring, reduced space, improper installations, fire principle, material wear, little or no lighting and etc. were detected.

In the background comes the lack of use of EPI, where it is verified that it has to do with the subjectivity of measuring the severity and probability, mainly, of the incidence of the adverse event, as Informed us Ripley (2008). It is necessary to inform that the use of EPIs do not prevent accidents! (in other words, EPIs mitigate the possible injuries caused by the accident) “The need and importance they have is in mitigating the risks and severity of accidents […].” (REVISTA CIPA, 2020th, p. 61)

In a given company, the directors aware of the importance of using the EPIs asked them to be the first to participate in the necessary training and to receive and use the equipment. Coming next the managers and supervisors who fulfilled the trainings, received the guidance, using the safety accessories routinely without question. And finally, the other workers who had already known about the initiative by the board, managers and supervisors in being examples for the program to have adherence and minimal resistance!

Responsible for this narrative, Prof. Eng. Paulo Ribeiro Neres[12] presents us with the moral of the story:

what makes the change is not the excellent speech, beautiful sayings written in communiqués stuck in murals and, neither, the threats of punishment regarding the mandatory use. What really solves is the example that comes from above. (REVISTA CIPA, 2020th, p. 61)

The procedures were in the third plan and are related to lack of knowledge, non-compliance with safety standards and conduct, misuse of tools, lack of attention and etc., according to a summary of table 2.

Table 2

Source: Annual Report on Safety at Work 2019

Disclosure to CIPA members

Adverse events (accidents and incidents) are disclosed to CIPA members – through a specific form, to be read in meetings of the staff of their OM/Group/Squadrons, aspiring to awareness of prevention by all garrison staff.

It is observed that in the work environment (workshop floor) it was the place where most non-conforming situations were reported (54.9% – 28/51) and that more adverse events occurred (57.7% – 15/26).

Considering the risks of the work environment (physical, chemical and biological) according to intensity, nature and concentration, with the potential to cause damage to the health of the military (maintainer[13]), therefore, and according to the Annual Report (2019), the importance of

implementation of the Environmental Risk Prevention Program (PPRA – in accordance with NR 9) in order to prevent or mitigate occurrences with damaged or defective tools, unprotected machinery, inadequate ventilation system, slippery floor, height work and other non-compliant situations. (BRASIL, 2019c)

Improvements in working conditions are the responsibility of the employer in accordance with the requirements of Regulatory Standard No. 9 (NR 9 – Environmental Risks), in its text of item 9.6.3.

The employer shall ensure that, in the event of environmental risks in the workplaces that put one or more workers in a serious and imminent risk, they can immediately interrupt their activities, communicating the fact to the superior direct to the appropriate measures. (BRASIL, 1999b)

To ensure safe working conditions, Occupational Safety Surveys (VST) or Safety Inspections (SI) need to be frequently carried out in order to prevent accidents and avoid them! To this end, it is necessary to effective the collective awareness of those involved in labor activities, the commitment to moral principles and safe conduct through risk situations and the adoption of preventive measures that plan to avoid unsafe conditions by the employer, signaling compliance with the law and contributing to the health and integrity of the maintainer staff.

To this end, some guidelines are suggested to mitigate work-related accidents:

- Conduct training of training and periodicals – still note many managers who do not realize how important knowledge is to ensure a safe work environment in carrying out operational activities with safety, comfort and quality for all involved.

- Complying with specific and related standards – observing and complying with them may be the difference between suffering or not having an accident!

- Identify, flag, communicate and monitor accident risk situations – many accidents happen due to lack of proactivity in the prevention process, because everyone must participate!

- Games are inadmissible during risky activities – these contribute to the risk factor, deconcentrate and are unprofessional.

- Conduct a preliminary analysis of implicit potential risks – knowing the risks, the accident can be avoided!

- Haste does not exist – do not turn the rush of other into self-incompetence!

- Search for improvements to the activities to be carried out – EPIs, techniques and constant updating.

- Complying with NR 6 and making use of specific EPIs – are essential devices in minimizing injuries caused in the event of an accident.

- Report adverse events – communicate to the relevant sectors and disclose to those responsible in the workplace.

9. FINAL CONSIDERATIONS

The Brazilian Air Force is no different from society, because adverse events (accidents) are also part of the “abiana[14]” reality, however much it has invested in human capital (empowering) the undesirable can be provoked.

It was in the work environment that more reports were recorded (54.9% – 28/51) and adverse events occurred (57.7% – 15/26) making it necessary to inform that accidents are caused (unconscious or conscious), but also they can be avoided by strengthening awareness of conducts and prevention measures.

The general objective was to discuss how work safety is presented within the scope of GUARNAE-NT, tied to the specific objectives of identifying the difficulties presented by the garrison with regard to work safety and to propose the implementation of realistic work safety conducts for the entire workforce.

It is believed that everything evolves and in the safety of work is not different, so the possibility of improvements is desired through the following actions:

- Implement the Section for the Prevention of Occupational Accidents (SPAT), directly subordinated to the commander of GUARNAE-NT and to which CIPA would be subordinated. The head of SPAT will accumulate the role of president of CIPA, according to model:

| SPAT | CIPA |

| Boss | President |

| Assistant | Vice president |

| Charged | Secretary |

| Auxiliary | Auxiliary |

| With accumulation of functions | |

Source: Author

- Change item 4.3.1 of NOPREP/ADM/14/2019, from “semiannual” to “monthly”, regarding the extended period of ordinary meeting, pursuant to item 5.23 of NR 5;

- Include an item in NOPREP/ADM/14/2019 that makes the CIPA member unavailable to other committees, while it is part of the CIPA committee. This unavailability aims to ensure the intensification of the supervision of cipa’s activities and in a committed, permanent and active manner, based on the preventive spirit and in the promotion of a relationship of constant dialogue and awareness of the garrison’s staff. In addition, it is also considered the need for specialization and availability of CIPA members, in order to be prepared and available to compete the Internal Scales to CIPA (preparation of Adverse Events Reports, Analysis of Risk Reports and instructions – classes, as well as, in monitoring the implementation of the related recommendations) in parallel with the routine attributions of the respective work sectors. (as drafted in ITEm 3.2 of NPA/CIPA_Ala 10/701/2019)

- Articulate with public and private agencies agreements or exchanges that promote the realization of training to CIPA members inherent to activities of prevention of work accidents, such as: NR 5, NR 6, NR 10, NR 20, NR 23, NR 33, NR 35, as well as encouraging training by CIPA members who have qualifications for this purpose.

- Create the highlight ed if “Occupational Safety” is to be given annually to committee members who present relevant services provided in the prevention of accidents at work, through the Commission, within the scope of the Air Force.

- Create for SPAT/CIPA members a differential in the uniform, in order to motivate and encourage, to make them recognized as a member of an important committee, before the staff and that may be a beanie or string in the green color safety (flag) – for use in the 8th or 10th RUMAER.

- Request vacancies for the Board of Conscripts (temporary) officers (QOCON) and Sergeants (QSCON) regarding professionals with the Specialization in Work Safety and Technical Course of Work Safety, respectively, to work with SPAT / CIPA.

- Encourage spat/cipa members with knowledge in the area of Work Safety (Engineers/Technicians) to share knowledge through training to other members.

Therefore, accidents at work are reported every day in all branches of society causing pain, suffering, damage to property, temporary or permanent removals and killing!

In view of this, popular knowledge teaches us that: “Safe died of old and suspicious still lives!” For this purpose, the promotion and reflection on the prevention of accidents through a systematic practice of occupational safety in the barracks, where military personnel (both sexes) expose themselves to the intrinsic risks of each military activity, which aims at this contemplation, promoting the effective of the Garrison of Aeronautics of Natal (GUARNAE-NT), in which the prevention of work accidents is alluded.

REFERENCES

BRASIL. Comando da Aeronáutica. Centro de Investigação e Prevenção de Acidentes Aeronáuticos (CENIPA). Disponível em: <http://cesv.cenipa.gov.br/index.php/sipaer/57-artigos/81-historico-do sipaer/publicado: segunda, 17 de julho de 2017, 16h50 | acessos: 9880>. Acesso em: 29/09/2020.

______. Comando da Aeronáutica. Comando Geral de Apoio. Instrução do Comando da Aeronáutica (ICA) 37-644, de 2015. Currículo Mínimo do Curso de Segurança do Trabalho. Boletim do Comando da Aeronáutica nº 049, de 16 de março de 2015.

______. Comando da Aeronáutica. Comando Geral de Apoio. Tabela do Comando da Aeronáutica (TCA) 37-11, de 2020. Cursos da Área do COMGAP. Boletim do Comando da Aeronáutica nº 002, de 06 de janeiro de 2020.

______. Comando da Aeronáutica. Comando de Preparo. Norma de Preparo (NOPREP) ADM/14, de 16 de outubro de 2019. Prevenção de Acidentes de Trabalho.

______. Comando da Aeronáutica. Guarnição de Aeronáutica de Natal. Norma Padrão de Ação (NPA) CIPA_Ala 10/701, de 1º de abril de 2019. Funcionamento da Comissão Interna de Prevenção de Acidentes de Trabalho (CIPA) da Ala 10.

______. Comando da Aeronáutica. Guarnição de Aeronáutica de Natal. Relatório Anual de Segurança do Trabalho 2019 da Ala 10, de 28 de novembro de 2019.

______. Comando da Aeronáutica. Instrução do Comando da Aeronáutica (ICA) 205-42, de 2011. Procedimentos Gerais de Segurança Aplicáveis aos Treinamentos, Cursos e Estágio. Boletim do Comando da Aeronáutica nº 247, de 29 de dezembro de 2011.

______. Diário Oficial da União – DOU. Página 13 da Seção 1, de 9 de fevereiro de 2018. Disponível em: <https://www.jusbrasil.com.br/diarios/177346553/dou-secao-1-09-02-2018-pg-13>. Acesso em: 04/06/2020.

______. Lei nº 6.880 de 09 de dezembro 1980. Estatuto dos Militares. Diário Oficial da União, D.O.U. de 11 de dezembro de 1980.

______. Ministério da Aeronáutica. Base Aérea de Natal. Instrução de Comando (IC) 49/A1, de 1º de abril de 1998.

______. Ministério do Trabalho e Emprego. NR 05 – Comissão Interna de Prevenção de Acidentes – CIPA. Brasília: Ministério do Trabalho e Emprego, 1999a. Disponível em: <https://enit.trabalho.gov.br/portal/images/Arquivos_SST/SST_NR/NR-05.pdf>. Acesso em: 09/09/2020.

______. Ministério do Trabalho e Emprego. NR 09 – Riscos Ambientais. Brasília: Ministério do Trabalho e Emprego, 1999b. Disponível em: <https://enit.trabalho.gov.br/portal/images/Arquivos_SST/SST_NR/NR-09-atualizada-2019.pdf>. Acesso em: 21/09/2020.

______. Ministério Público do Trabalho. Observatório Digital de Saúde e Segurança no Trabalho. Disponível em: <https://www.gov.br/mdh/pt-br/assuntos/noticias/2018/marco/mpt-lanca-nova-versao-do-observatorio-digital-de-saude-e-seguranca-no-trabalho>. Acesso em: 09/09/2020.

BISSO, Ely Moraes. O que é segurança do trabalho. São Paulo: Editora Brasiliense, 1990.

FORÇA AÉREA BLOG. Segurança e prevenção de acidentes do trabalho: como a FAB trabalha. Disponível em: <http://www.forcaaereablog.aer.mil.br/index.php?option=com_content&view=article&id=139:seguranca-e-prevencao-de-acidentes-do-trabalho-como-a-fab-trabalha&catid=2&Itemid=104>. Acesso em: 31/08/2020.

FILHO, Hermelindo Lopes. Nas Asas da História da Força Aérea Brasileira.2012. Disponível em : <http://www.faap.br/hotsites/asas-da-historia/livreto%20Nas%20Asas%20da%20Hist%C3%B3ria%20Da%20For%C3%A7a%20A%C3%A9rea%20Brasileira.pdf>. Acesso em 27/08/2020.

IBC. Instituto Brasileiro de Coaching. Quais são os recursos de uma empresa? Disponível em: <https://www.ibccoaching.com.br/portal/quais-sao-os-recursos-de-uma-empresa/>. Acesso em: 09/09/2020.

NOVA ESCOLA. Voar: o sonho, o projeto e a realização de Santos Dumont. Disponível em: <https://novaescola.org.br/conteudo/1149/voar-o-sonho-o-projeto-e-a-realizacao-de-santos-dumont. Acesso em: 31/08/2020.

PIZA, Fábio de Toledo. Informações básicas sobre saúde e segurança no trabalho. São Paulo: CIPA, 1997, p.24.

REVISTA CIPA: Caderno Informativo de Prevenção de Acidentes. Contra quedas. São Paulo: Editora Casa Nova, 2019, ano 41, n. 478, p. 55-58.

______. Linha de frente. São Paulo: Editora Casa Nova, 2020, ano 42, n. 488, p. 60-61.

______. Solidariedade na crise. São Paulo: Editora Casa Nova, 2020, ano 42, n. 489, p. 82-83.

RIPLEY, Amanda. O impensável – quem sobrevive quando ocorre um desastre e por quê? Disponível em: <https://prolifeengenharia.com.br/percepcao-de-riscos-no-ambiente/>. Acesso em: 05/10/2020.

THANKS

To the commander of the Air Force Garrison of Natal, Mr. Brigadier of The Air Marcelo Fornasiari Rivero for his confidence in the academic treatment of information and to Colonel Engineer Enio Macêdo do Nascimento – President of the Internal Commission for Accident Prevention of Ward 10 for the generosity, strength and partnership of a teacher who through his guidelines allowed to complete this work.

ANNEXES

- Extract from pages 11 and 12 of the Annual Report on Safety at Work 2019.

APPENDICES

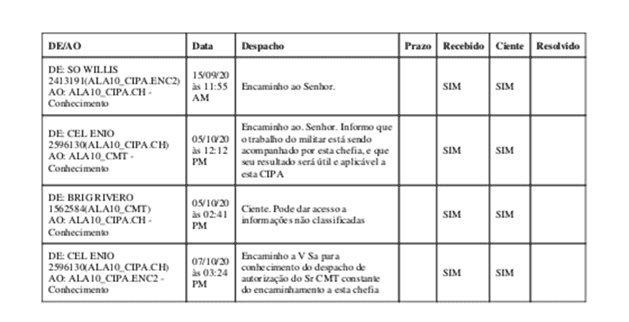

1. Request for use of data from the 2019 Annual Work Safety Report.

- Dispatches for use of data from the Annual Report on Safety at Work 2019.

APPENDIX – FOOTNOTE REFERENCES

2. Accident Prevention Information Book is a specific publication for the areas of Hygiene, Safety and Labor Infortunistics, aimed at the total safety of man, labor and the company, belongs to Cipa Fiera Milano Publicações e Eventos Ltda.

3. Risk is understood – the probability of occurrence of an event, which can be positive (opportunities) or negative (damage – loss /claim).

4. Risks – in the plural, because these are composed of five, namely: Physical, Chemical, Biological, Ergonomic and Accident (Mechanical), as annex IV – Risk Map of NR 5.

5. Department of Airspace Control (DECEA), General Personnel Command (COMGAP).

6. Work Safety Course (CST) – provided for in the Aeronautical Command Table (TCA) 37-11/2020, “Courses in the Area of the General Support Command (COMGAP).

7. This number is oscillating due to the specificities of the military career (movements, courses, internships, commissioning, etc.) where members constantly have to be replaced.

8. They are the reported of situations of risk or unsafe condition.

9. After the repeal of Provisional Measure No. 905, of November 11, 2019, the provisions of Law No. 8,213/91 (accident on the way to employment is again considered work purposes).

10. The injured after the due calls complies with expedients.

11. The injured after the calls is excused from office.

12. Paulo Ribeiro Neres – Work Safety Engineer, assistant expert in dangerousness and unhealthiness processes, professor of technical course of Work Safety, training instructor of NR-12 (Safety at Work in Machinery and Equipment).

13. (military) professionals working in maintenance.

14. Inherent to FAB (fabiano/fabiana).

[1] Master’s degree in Educational Sciences from FACSIDRO (Faculty of Sidrolândia/MS); Specialist in Teaching in Higher Education at UnP (Potiguar University); Technologist in Enterprise Safety Management at UnP; Brazilian Air Force Petty Officer, Military Instructor, Occupational Safety Multiplier and member of the Internal Commission for Accident Prevention (CIPA) of the Christmas Air Force Garrison (GUARNAE-NT) for more than 20 (twenty) years.

Submitted: December, 2020.

Approved: December, 2020.