ORIGINAL ARTICLE

LIMA, Leandro Jose Barbosa [1], HAMZAGIC, Miroslava [2]

LIMA, Leandro Jose Barbosa. HAMZAGIC, Miroslava. The reengineering of the disengineering of oil and gas wells. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year. 07, Ed. 07, Vol. 03, p. 23-68. July 2022. ISSN: 2448-0959, Access link: https://www.nucleodoconhecimento.com.br/engineering-mechanical-engineering/reengineering, DOI: 10.32749/nucleodoconhecimento.com.br/engineering-mechanical-engineering/reengineering

ABSTRACT

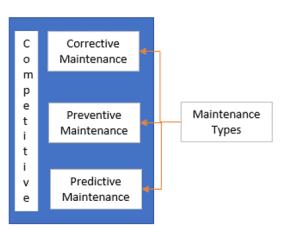

Reengineering is a term created in the 80s, which focuses on rethinking the way companies carry out their activities, in order to reduce costs, improve customer service and become more competitive. Disengineering, on the other hand, considers what to do with the industrial facilities once the enterprise is no longer in activity. This time, this article aims to answer the following guiding question: What are the possibilities of using structures and materials from already depleted wells using the concepts of Reengineering of Disengineering? After the document analysis, it was possible to establish an alternative proposal to increase the useful life of Oil and Gas wells through the applied concepts.

Keywords: Disengineering, Reengineering, Oil, Wells, Reservoir.

1. INTRODUCTION

An oil and gas well is a major engineering work, its construction can take days or even months, and are essential for generating energy from fuel.

Thomas (2001) clarifies that the fuel that societies consume as mechanical energy in vehicles, in the form of heat energy in homes or industries, or, in the form of electrical energy in the various appliances that make the economy spin, is just the end result. of the existing chain to produce energy (THOMAS, 2001).

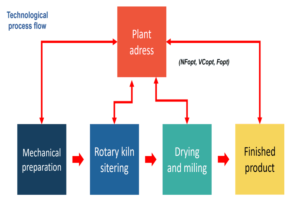

In a complex production chain, each step of the process is important, and cost-effectiveness and effectiveness of performance must be carried out at each step. Thus, wells are considered one of the steps likely to seek greater effectiveness in their life and performance. In this context, there is the importance of Reengineering and Disengineering.

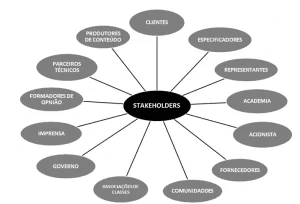

Reengineering is a term created by Michael Hammer and James Champy, which focuses on rethinking the way companies carry out their activities in order to reduce costs, improve customer service and become more competitive (HAMMER; CHAMPY, 1993), Desengenharia considers what to do with industrial facilities once the enterprise is no longer in activity and was described by Luis Enrique Sanchez in 2001.

Within this context, as in other industry applications, reengineering can give other destinations to these metallic materials, especially in the case of already depleted reservoirs, not economically viable, or wells that may not be of interest to the oil industry. Wells that have a known geological configuration, that often already have capacity as a reservoir, and that often already have some structure created, but how can reengineering be used in these cases? How can these structures still return their value to society?

It is these answers that act as the objective of this investigation, carried out through the demonstration of well drilling and its variables, the recognition of oil wells, depletion, and finally, the alternatives through the concepts of Reengineering and Disengineering.

2. GENERAL CLARIFICATIONS ABOUT WELLS

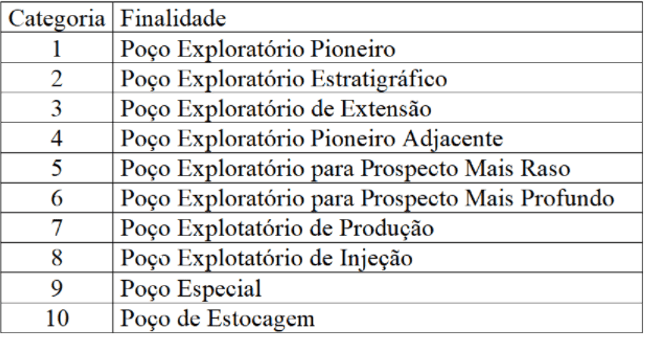

According to the classification of the Agência Nacional do Petróleo – ANP (2017)[3], there are several types of wells that can be drilled. Table 1 promotes the classification of 10 types of categories:

Table 1 – Classification of Wells in Brazil

Each of the types of wells has specificities, durability and differentiated effectiveness, making it a challenge for organizations to work at their maximum potential.

There are very unique characteristics that define where a well will be drilled and the potential for a region to be or not to be a producer of oil and natural gas, which also includes cases where there may be controversies.

Thus, for the oil and gas reservoir to be present, a very unique configuration is needed, especially in relation to sedimentary rocks, and other types of rocks, which must imply a categorization and structuring of a source rock, a storage rock and a sealing rock or structural trap that guarantees the watertightness of the reservoir, without which the oil or gas could be released to the surface, therefore techniques such as magnetometry, gravimetry and reflection seismic are used.

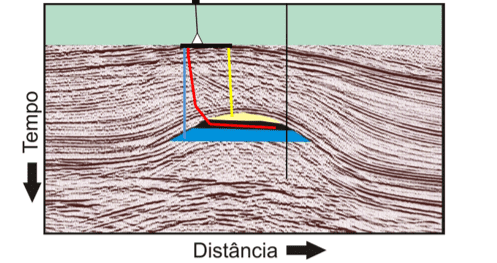

Figure 1 shows a condition of a reservoir in seismic perspective of reflection, showing 3 wells drilled in yellow (vertical), blue (vertical) and red (horizontal) (THOMAS, 2001).

Figure 1 – Wells in perspective of the reflection seismic

When the ideal conditions are found, exploratory wells are drilled to confirm the conditions observed on the surface, as well as, the depths of the rocks are confirmed by the core techniques, for this, petrophysical analysis and geopaleontology are used, by indirect methods. such as those used by geophysics in well logging (THOMAS, 2001). In addition to the most well-known characteristics, it is important to understand the coefficients of rock fracture, porosity and permeability, described by Darcy’s law, that allow estimating the potential of the reserve, and the recovery factor.

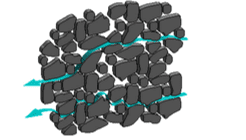

Figure 2 demonstrates the shape of the fluid that flows between the voids in the rock (SANSONE, 2015).

Figure 2 – Illustration of rock permeability

It is important to point out that although ideal geological and watertight conditions are often confirmed, many of these drilled wells end up being abandoned, as reserve expectations may not be considered good because they are dry, carbon dioxide, water, hard or soft, so permanent cement plugs are used to seal these reservoirs (THOMAS, 2001).

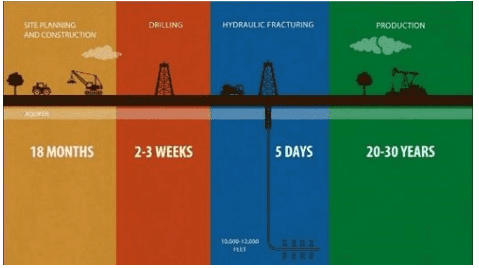

Figure 3 presents a perspective of the time required at each stage in the process of building an oil well until the production phase (CONOCOPHILLIPS, 2015).

Figure 3 – Illustration of well life cycle time

Wells that are considered productive have their construction process completed, and in some cases auxiliary water pumping wells are drilled at the ends to allow greater use of the reserve present in the reservoir, thus increasing its recovery factor.

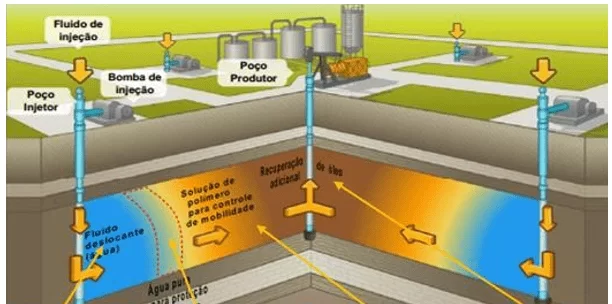

Figure 4 demonstrates how fronts are formed for the non-predatory production of oil and natural gas reservoirs (ROSA, 2006).

Figure 4 – Illustration of the injection process for the production of wells, with advance front.

In addition to the periodic maintenance of the wells, the reservoirs also undergo intervention processes in order to maximize their production. Examples of these processes include: chemical stimulation processes, hydraulic fracturing and re-entry processes using techniques such as coiled tubing. These actions aim to provide the maximum amount of oil in the shortest time to obtain a return on investment.

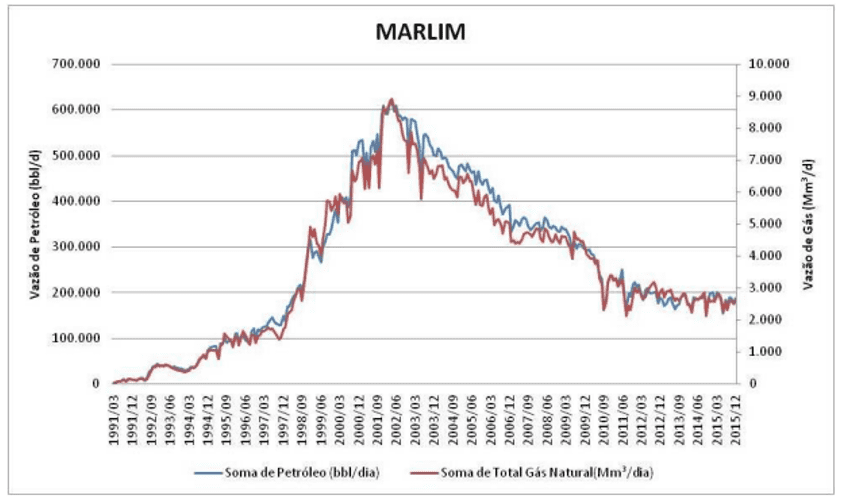

Graph 1 shows the oil and natural gas production of a field over the years. It is observed that at the beginning of the curve there is an increase in production due to the drilling of more wells in this field to maximize its production, as well as other interventions that may be the addition of water or CO2 injection wells (EOR – Enhanced Oil Recovery), in addition to the techniques mentioned above, until a period of decline in production begins (ROSA, 2006).

Graph 1 – Production of a field over time

It is possible to observe that, at a given moment, the production costs of a well end up not being viable for the holder of the field, which can be defined by the abandonment of the well, by the transfer to communities, or, for other smaller companies, either by the low production or by significant changes in the oil-water, gas-oil ratios, or the production of sand; at times when an intervention is no longer worth it (ROSA, 2006; THOMAS, 2001).

There are successful cases where, through investment and the use of more advanced techniques, it is possible to automate the process of separating unwanted by-products and increase production from wells, as recently observed in Brazil, where a private company managed to increase production from mature fields by 30% (JÁCOME, 2021).

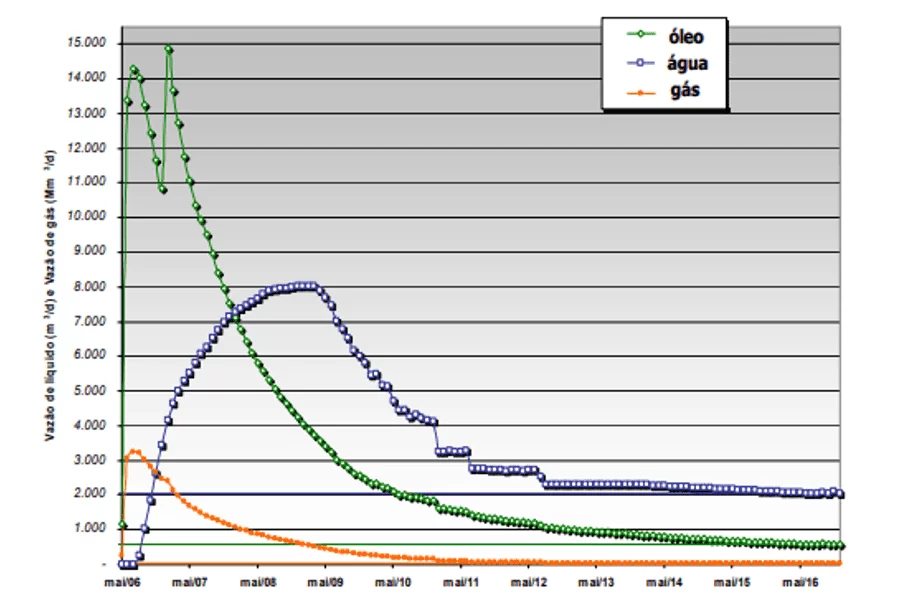

Graph 2 demonstrates an example of how the production of oil, water and gas can behave over the years in a reservoir.

Graph 2 – Production of water, oil and gas over time

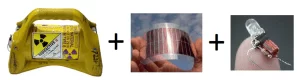

At the end of the life cycle of a well, a reservoir or when maintenance of the well is necessary, the equipment is removed from the wells and then returned to the surface (THOMAS, 2001) and needs to be treated for a subsequent recycling process. However, in some cases there is the presence of the production of materials such as norm and tenorm[4] that need a very specific destination for the reuse of metallic material (LINCERADIO, 2021).

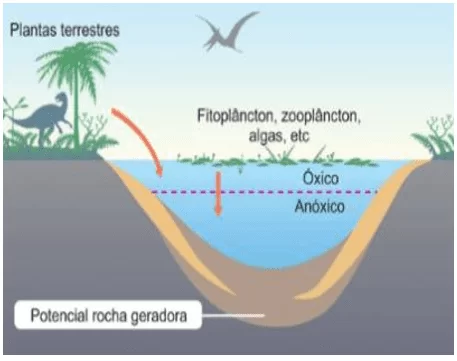

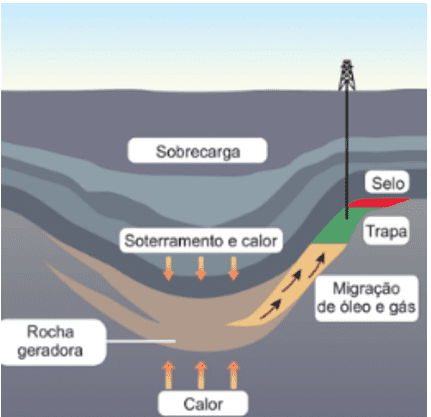

3. THE OIL RESERVOIR

The main reservoir rocks are limestone and sandstone, their formation has been going on for thousands of years, mainly in conditions related to the presence of sedimentary basins. As seen in figure 5a, the accumulation of organic matter in thousands of years will form in source rock (MATLAK AL-HAJERI, et al., 2009; ROSA, 2006; THOMAS, 2001).

Figure 5a – Sedimentary basin formation

In figure 5b, the shale, which with the action of pressure and temperature will produce hydrocarbons, which under certain conditions can migrate to porous sedimentary rocks that will store them, in the existence of some type of entrapment mechanism, sealing rock or structural trap (MATLAK AL-HAJERI, et al., 2009; ROSA, 2006; THOMAS, 2001).

Figure 5b – Oil generation process from the sedimentary basin illustrated in Figure 5a

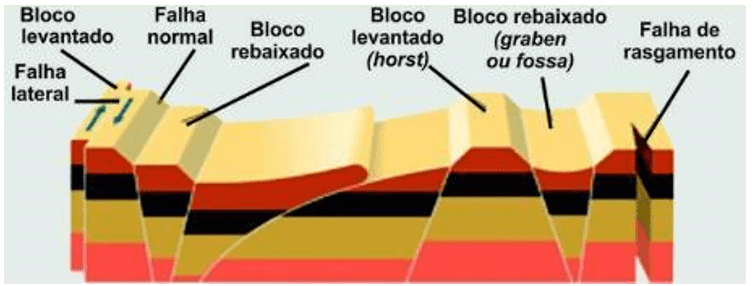

According to Castro Faria (2013) and Rosa (2006), the structural trap can happen in several ways, one of them being the saline domes, or alterations that occurred in rocky deposits in rivers of sedimentary basins or even alterations that occurred during the process of geoformation.

Figure 6 – Illustration with the different types of geological faults

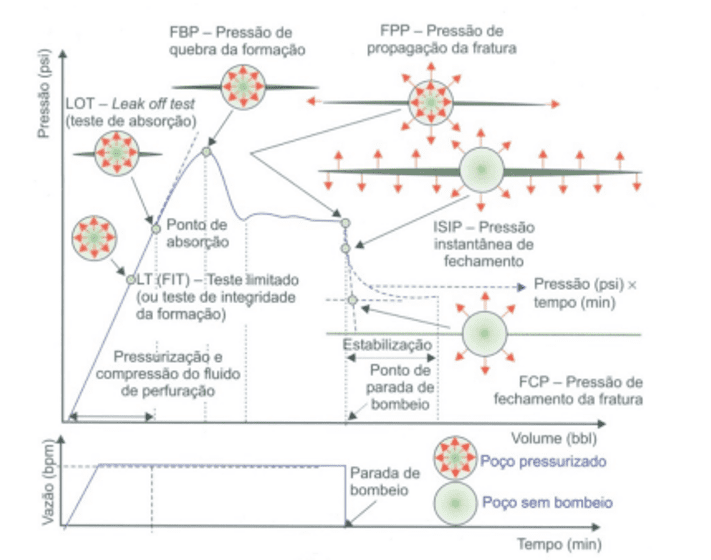

It is important to note that the oil reservoir has this name precisely because it guarantees, up to certain pressure limits, the ability to maintain its watertightness. Formation pressure, porosity and permeability are characteristics that determine the limits of pressure that can be contained in this reservoir without causing damage or fracture to the formation, porosities and permeability determine the capacity of how a fluid can flow through this rock, being these important characteristics to determine the capacity or volume of the reservoir and the reserve, as well as, to determine the recovery factor and the estimated production curve, which can be aided by the formation test.

Graph 3 demonstrates one of the types of pressure tests performed on reservoirs. Knowing the pressure limits helps to understand the capabilities of future uses of these reservoirs (PUC/RJ, 2011; ROSA, 2006; THOMAS, 2001).

Graph 3 – Formation Pressure Test

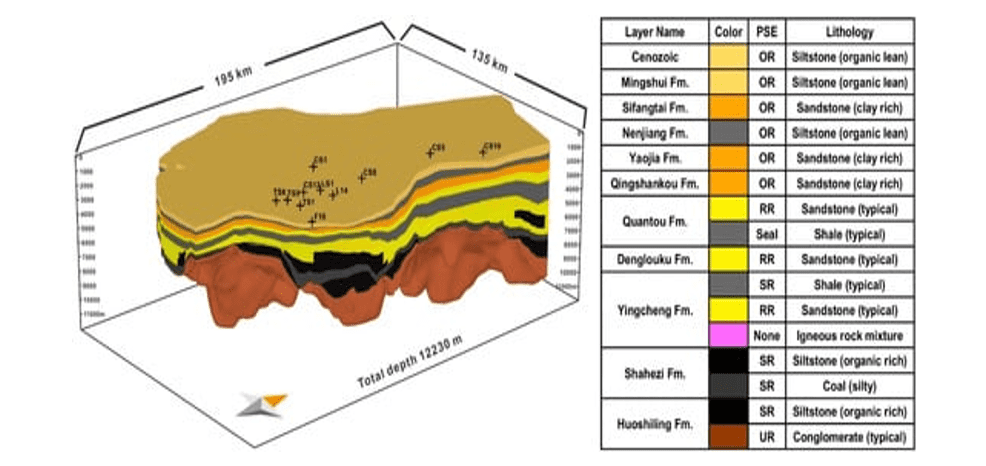

Based on seismic information, geophysical profiles, and formation tests, including permeability and porosity, it is possible to determine the estimated value of the volume and empty spaces of a reservoir, and thus, estimate its reserve or capacity (ROSA, 2006). Figure 7 demonstrates the overlapping of different sedimentary rocks that form a region of interest for the oil industry. When a deposit is depleted, it can serve to accumulate other types of materials in addition to the kilometer-deep well (ZHANG et al., 2019).

Figure 7 – Subsurface illustration

These could be in different geolocations and can be transported in different modes within the special transport conditions required, depending on the product, and, as exemplified in some modes.

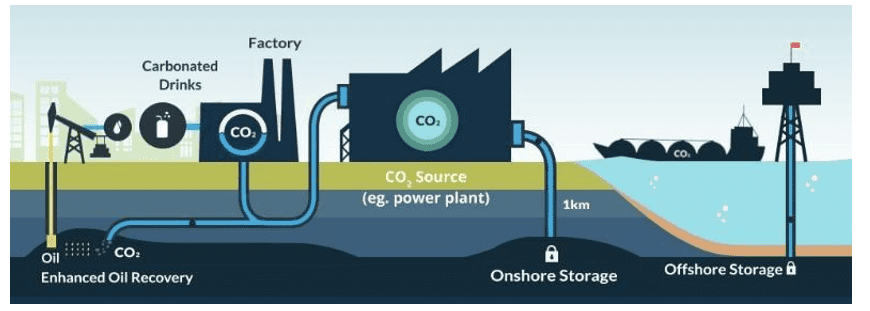

Figure 8 (pipelines and ships/barges) (GOVERNMENT OF THE REPUBLIC OF TRINDAD AND TOBAGO, 2021).

Figure 8 – Model of the Carbon Capture and Sequestration Process

3.1 QUANTITY OF DRILLED WELLS AND THE POTENTIAL

Tables 2 and 3 were made using data published by the National Agency of Petroleum, Gas and Biofuels and demonstrate the size of the number of wells drilled in Brazil year by year, both onshore and offshore.

Table 2 – Condition, quantity and depth of wells drilled in Brazil

| Classification | Number of Wells | Average Measured Depth (meters) |

| Abandoned | 11870 | -2898 |

| Devastated | 2624 | -1387 |

| Evaluation | 7743 | -3186 |

| In use | 7903 | -2193 |

| Grand total | 30140 | -1070 |

Authors – Adapted from the Agencia Nacional do Petróleo, Gas and Biofuels (2021).

According to the figures in table 2, we can consider the possibility of using almost half of the 30 thousand wells drilled in Brazil for storage purposes, representing a great opportunity for intervention and reengineering applications.

Table 3 – Condition, quantity and depth of earth wells drilled in Brazil

| Classification | Number of Wells | Average Measured Depth (meters) |

| Abandoned | 6973 | 1300 |

| Devastated | 2218 | 1351 |

| Evaluation | 5675 | 1186 |

| In use | 8418 | 1102 |

| Grand total | 23284 | 1179 |

Authors – Adapted from the Agencia Nacional do Petróleo, Gas and Biofuels (2021)

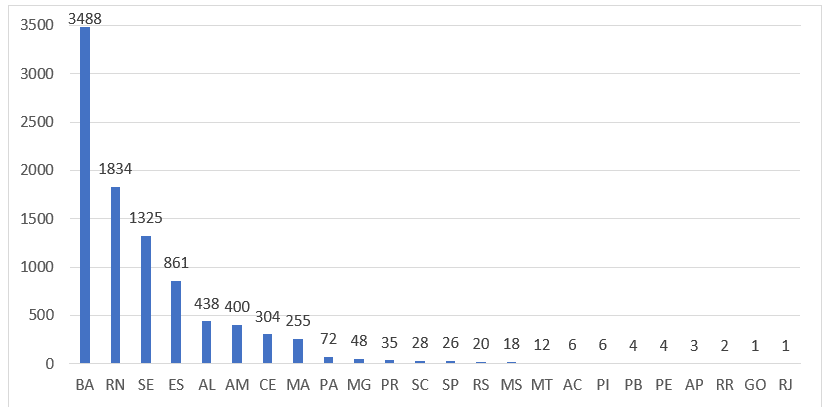

As an illustration of the potential volume available, wells are generally drilled in diameters ranging from 5 inches to over 28 inches, and as noted in Graph 4, wells at approximately 1300 meters in depth, and although it is assumed that the entire well is 5 inches or 0.127 meters (THOMAS, 2001).

Graph 4 – Number of Earth Wells in a condition of abandonment or devastated

Thus, a minimum of 16m3 of volume, in addition to the volume of the reservoir, which, as we can see in Figure 9, in the worst case produces 34 barrels of oil per day or 5.4 cubic meters per day, almost 2000m3 per year, production that extends over years, which with respect to the 9000 wells in conditions of abandonment or devastation, on land, would be a minimum volume of 17,739,000 meters3 of storage per year, disregarding aspects of pressurization (emphasis by the author).

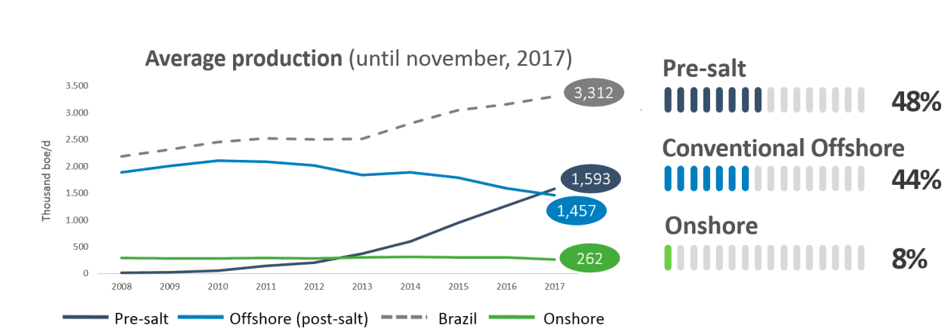

Figure 9 – Number of wells and production in different environments

Graph 5 demonstrates how this production development in thousands of barrels of oil per day in different types of fields has been developing in Brazil.

Graph 5 – Average production in different environments

3.2 REENGINEERING AND DISENGINEERING

As already mentioned, Disengineering is a common process at the end of the life cycle of an enterprise, when it is no longer economically viable to reform an industrial plant, or to proceed with the production of an oil well. Some of these structures end up being abandoned and having no future use or value, as the investment has been completely depreciated, and in some cases even generating treatment costs before decommissioning. Incorrectly abandoned structures can generate soil or groundwater contamination in the long term by the decomposition of containers or barriers (SÁNCHEZ, 2001).

Reengineering, which conceptually as something to redesign or drastically reform, comes precisely to give greater value to structures that are already depreciated or that are not economically viable to operate and can even be a liability or generate costs and risks, being In this way, an opportunity to recover capital for investors and, not a mere cost, but to compose the expected cost with the project throughout its cycle, especially in reservoirs that may have a lot of use (GOMES et al, 2005; SÁNCHEZ, 2001).

3.3 RECYCLING AND DECONTAMINATION OF METALLIC MATERIAL

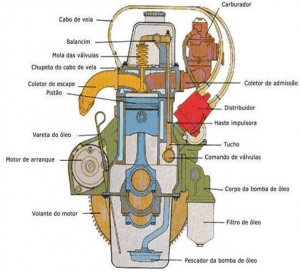

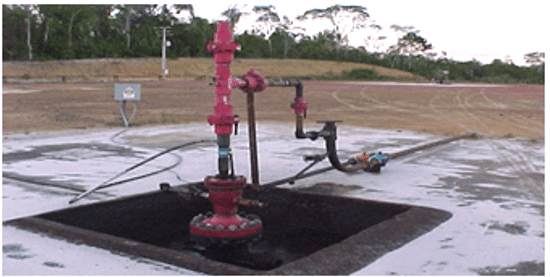

One of the most obvious reasons for recycling metallic material is the reduction in energy consumption, in addition to preserving finite resource reserves and lower environmental impact in exploration. It is also important to point out that there are materials that are rare in nature and that recycling can be a more voluminous or simpler source of resource than nature itself. In Germany, for example, there are sensors that detect the presence of non-ferrous metals in the recycling process. These recycling processes can lead to a reduction in energy consumption of up to 88%, electricity consumption up to 35%, and water consumption up to 87%, depending on the technique used (VISSER, 2014). Figure 10 demonstrates an example of a real surface installation of an earth well in production.

Figure 10 – Appearance of a well in production

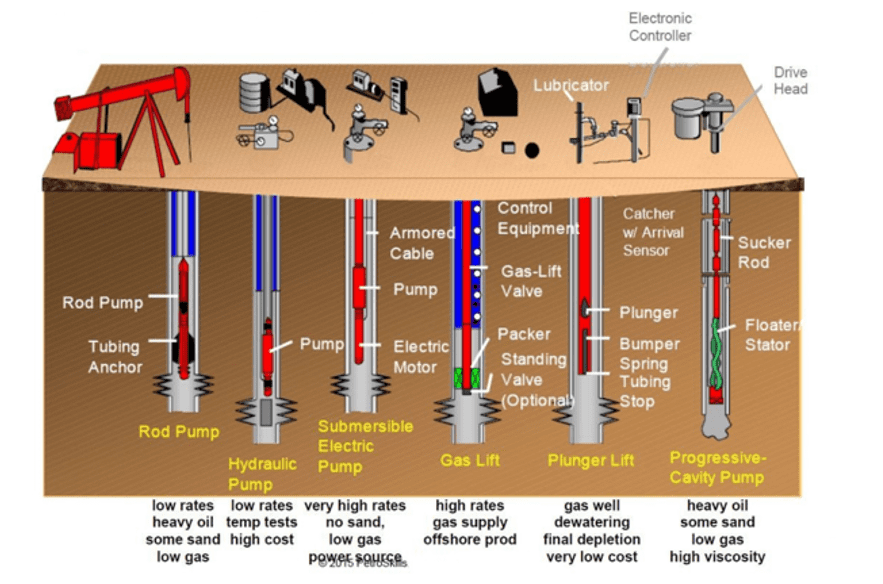

In figure 11 it is possible to observe the different types of possible systems apparent on the surface and subsurface that can later be removed for decontamination and recycling (PETROSKILLS, 2017).

Figure 11 – Different types of completed wells

Many of these materials may require specialist cleaning due to the possibility of containing oily residues, NORM (Naturally Occurring Radioactive Materials) or TENORM (Technologically Enhanced Naturally Occurring Radioactive Materials) (LINCERADIO, 2021).

Oily waste can be cleaned and subsequently treated, following landfill, incineration, landfarming processes, washing contaminated sand (in the case of soils or contamination), solidification and co-processing (GOVERNO DE SÃO PAULO, 2021). The return of these residues to oil wells or reservoirs in a controlled condition can also be considered as the scope of this work.

NORM is present in nature in different rocks or minerals, they usually have very low radiative emission rates and also low impact on people, but some processes such as oil production, in addition to other anthropogenic activities, can lead to the accumulation of materials containing NORM, increasing its concentration, and thus increasing the potential for affecting individuals who may be exposed, thus, it is important that materials that have accumulated NORM are decontaminated before being returned to nature. Within the decontamination process, we can include dilution or chemical extraction, mechanical extraction (using brushes, for example) or by water jet, and later this contaminated material can be sent to final destination according to the plan of radioactive waste from the facility (LINCERADIO, 2021).

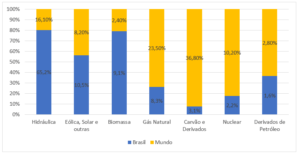

3.4 USE OF THE WELL AS A SOURCE OF GEOTHERMAL ENERGY

As its name implies, the oil and gas reservoir is a reservoir that, at the end of its useful life, can be easily adapted for the storage of other materials, or even take advantage of its geothermal potential, depending on the region where it was drilled, to generate electricity or hot water, either by means of steam, using turbines or other technologies that can take advantage of the heat already coming from the formation and with a lower carbon footprint to complement the calorific power of the fluid to generate steam and consequently more electricity, or even, using thermoelectric generators, seebeck effect.

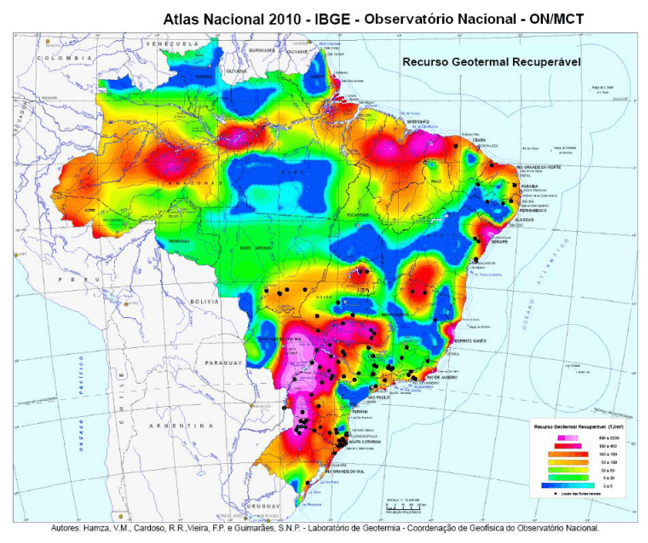

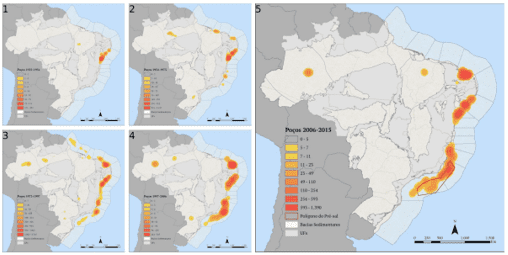

Figure 12 can be used to compare the regions where wells were drilled (12b) with the geothermal potential of each area (12a), thus determining the best regions for the use of existing structures (DUARTE and CATAIA, 2019; SWAROWSKI ARBOIT, et al., 2013).

Figure 12a – Zones of higher temperatures in Brazil

Figure 12b – Areas where there are wells drilled

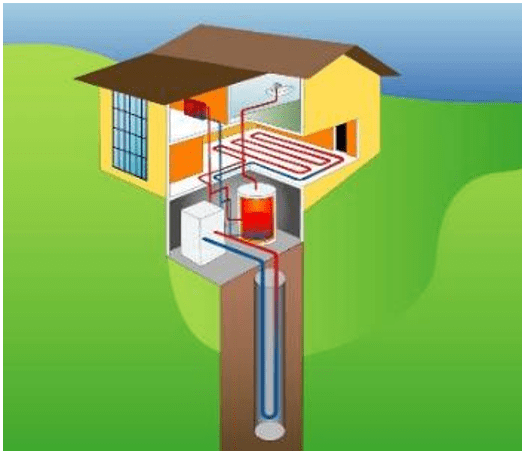

In Figure 13 there is a geothermal application where the temperature of the well or reservoir is not enough to generate steam, however, it is enough to exchange heat with the environment and help in residential heating.

Figure 13 – Model of geothermal well for domestic or industrial heating

The seebeck effect happens when a temperature gradient is applied in a circuit with different conductors, which generates electricity (ZHOU, et al., 2021).

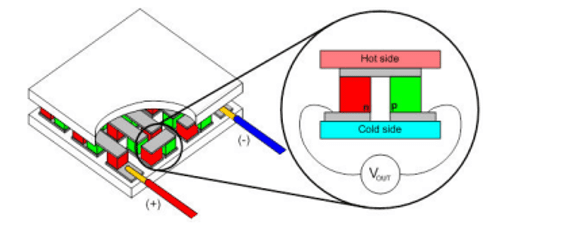

Figure 14 demonstrates how a Seebeck-Peltier system board works (SILVA, et al., 2013).

Figure 14 – Plate used for power generation according to the Seebeck-Peltier effect

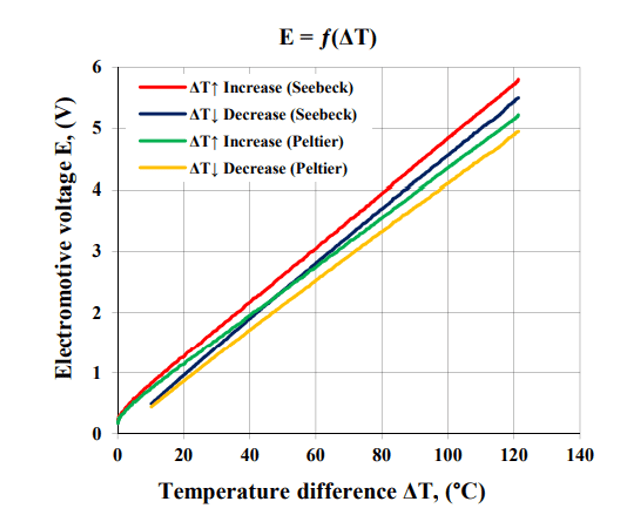

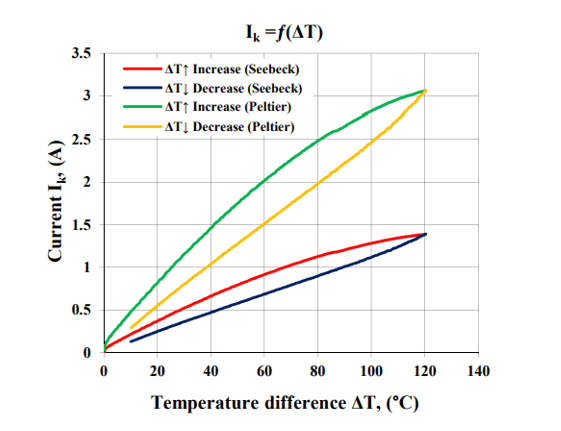

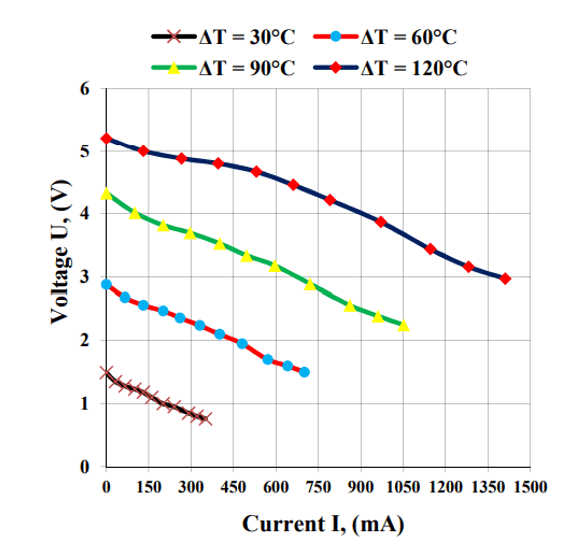

Graphs 6, 7 and 8 demonstrate the voltage and current potential that can be reached with a 1 cm2 Seebeck-Peltier module (IVANOV et al., 2021).

Graphs 6 – Voltage and current curves with a 1 cm2 Seebeck-Peltier module

Graphs 7a – Voltage and current curves with a 1 cm2 Seebeck-Peltier module

Graphs 7b – Voltage and current curves with a 1 cm2 Seebeck-Peltier module

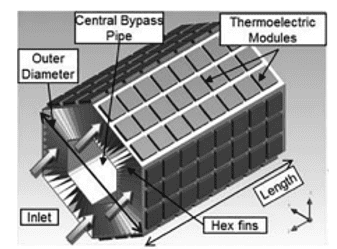

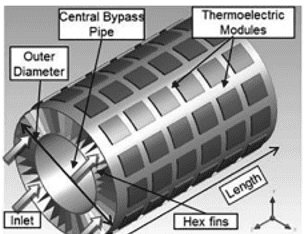

One configuration to increase energy recovery using the Seebeck effect is by series of modules, as proposed in figures 15 a and b, which would multiply the power effect observed in graphs 6, 7 and 8 (SHEN; TIAN; LIU, 2019).

Figure 15a – Configuration to obtain optimal power for Seebeck-Peltier modules

Figure 15b – Configuration to obtain optimal power for Seebeck-Peltier modules

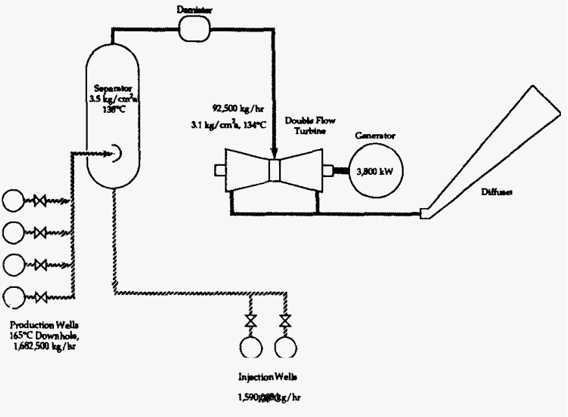

Figure 16 demonstrates the operation of turbines with steam from wells that have a temperature above 177ºC (SHULMAN, 1995).

Figure 16 – Steam generation circuit and turbine power supply through geothermal wells

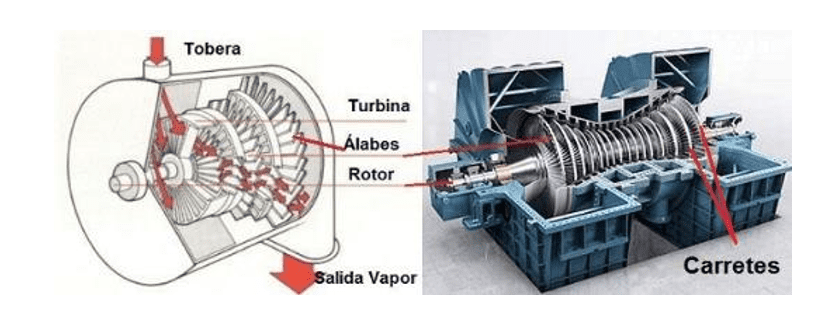

Figure 17 demonstrates how a steam turbine works, where the entry of steam takes place through the pipe, passing through different stages with the pallets, taking advantage of the thermal expansion of the gas, to maximize the rotation of the turbine and consequently more generation of energy (AREATECNOLOGIA, 2021).

Figure 17 – Illustration of a steam turbine

In some cases, the geothermal potential of a reservoir or well can be used to raise the temperature to a certain value, using biomass or biogas as fuel more efficiently, thus reducing the carbon footprint.

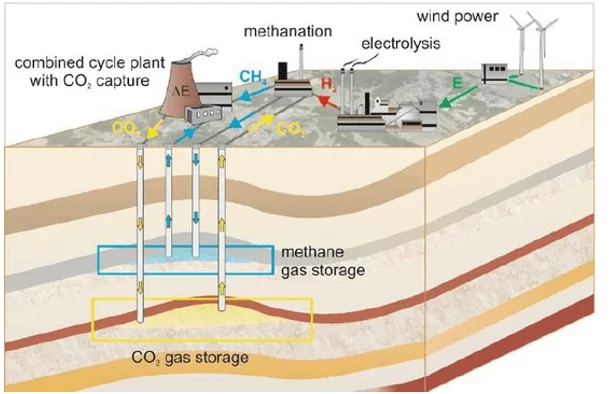

3.5 USE OF THE RESERVOIR FOR THE STORAGE OF METHANE AND CO2

Exploring its use as a reservoir, taking into account watertightness, structure and available volume, some options for its use could be the permanent storage of materials such as carbon dioxide (CO2) (DW PLANET A, 2021), production water (water that is produced during oil production that is very hard, and that is not always easily disposed of) (ROSA, 2006). Another option would be for the destination of other products that pose health risks, such as the end of the nuclear fuel cycle (SORENSEN, 2019).

In figure 18, it is possible to see a system adapted for storage.

Figure 18 – Subsurface illustration for CO2 injection for permanent storage

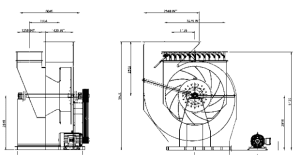

Oil reservoirs could also be used to store compressed biogas. Multi-stage centrifugal compressors (MODEKURTI, et al., 2017), as these are considered essential for the process of storing gasses in reservoirs (ROSA, 2006) or, transport by pipeline, in order to allow their permeability within the rock formation in the supercritical stage (MODEKURTI, et al., 2017).

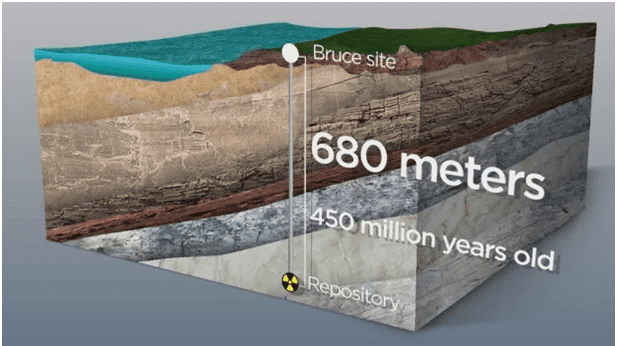

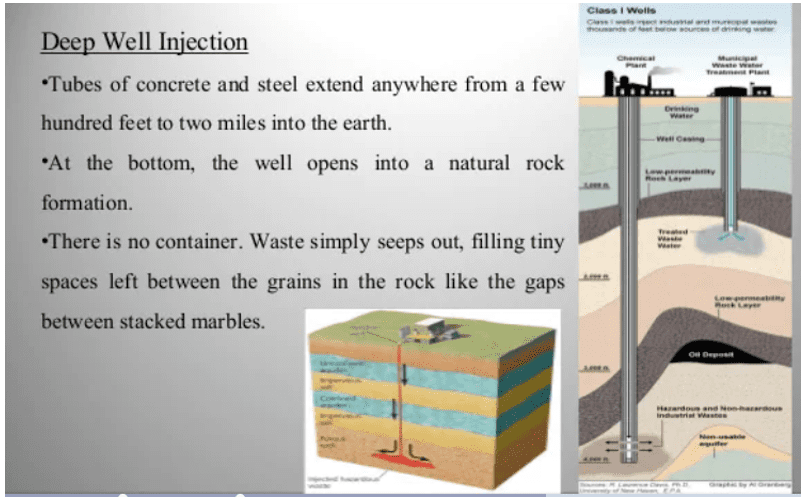

3.6 USE OF THE WELL FOR THE STORAGE OF TAILINGS

The storage of hazardous materials, as a final destination, depends a lot on more detailed analysis of the geological stability of the region to avoid leaks and risks of contamination of groundwater or other formations. As previously described, it may happen that materials go to landfills or surface regions that end up occupying areas that could have another type of use, also impacting the value of the region (SÃO PAULO, 2021).

Nuclear fuel also ends up being a problem for the energy industry, since this by-product still maintains levels of radioactivity for a few hundred years (US ENERGY INFORMATION ADMINISTRATION, 2020). Some countries are investing heavily in creating caves for their storage as a definitive solution, however, depleted or dry exploratory wells could be good structures for the permanent storage of these materials (FINLÂNDIA, 2021), respecting rules that still need to be created. Nuclear Energy is an energy that does not emit CO2, favors a more positive and sustainable reading, having great potential to help in the growth of energy demand (US ENERGY INFORMATION ADMINISTRATION, 2020).

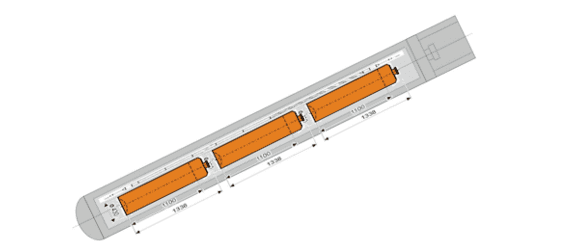

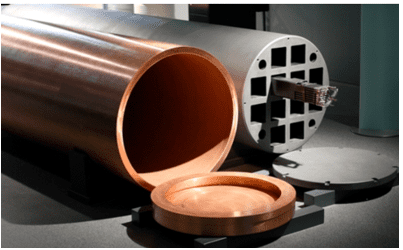

Figure 19 exemplifies an option to permanently store depleted radioactive material for its original purpose (FINLÂNDIA, 2021). According to Bracke, et al., (2017), two storage alternatives that would meet the principle of multiple barriers would be: the deepening of the wells and the previous encapsulation of the material.

Figure 19 – Subsurface illustration for the potential storage of depleted radioactive material

Figure 20 – Container module for the storage of hazardous materials

In the Finlandês case, “the spent fuel will be placed inside a graphite cast steel honeycomb (right) contained in a copper drum (left)”.

Figure 21 – Illustration of a module for the underground storage of depleted radioactive material

Figure 22 – Illustration of material cementation in the subsurface

3.7 USE OF RESERVOIRS FOR THE STORAGE OF AMMONIA OR HYDROGEN

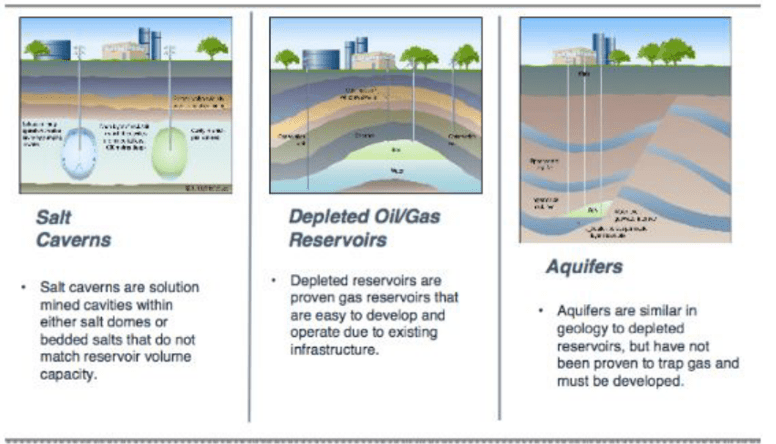

The storage of other materials, such as Ammonium or Hydrogen, is indicated by Sandia National Laboratories (2011) as a viable option for the use of depleted wells.

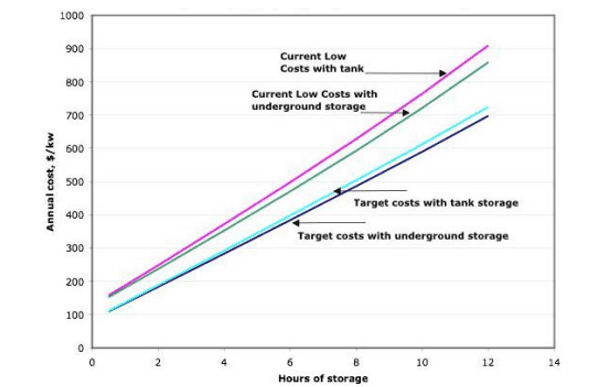

The cost of large-scale underground storage is a more cost-effective solution than other solutions, as one of the problems with Hydrogen is the degradation that takes place in tanks and the need for tanks that need large pressure capacities and high resistance to degradation/corrosion.

Graph 9 shows a comparison between the cost of storing hydrogen in tanks or underground in a period of 1 year (SANDIA NATIONAL LABORATORIES, 2011).

Graph 9 – Comparison of hydrogen storage costs in different options.

Figure 23 shows some storage options proposed by the study, including the case study of this work, demonstrating the depleted reservoirs with ready infrastructure (SANDIA NATIONAL LABORATORIES, 2011).

Figure 23 – Different options for hydrogen storage

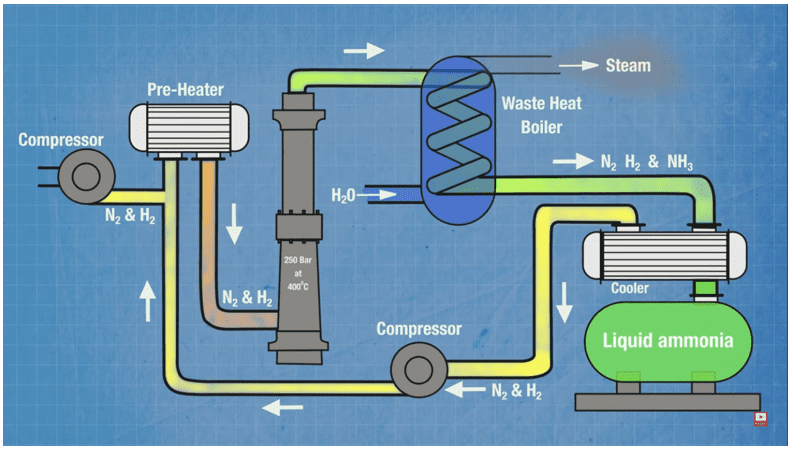

Ammonia is produced on a large scale using the process known as Haber-Bosch, a process that produces ammonia very quickly, but with high rates of CO2 emissions. This process combines Hydrogen with compressed Nitrogen at 250 bar and temperatures up to 400 degrees Celsius. The process uses nitrogen and hydrogen separated from their natural sources, despite the possibility that the production of hydrogen by electrolysis is the simplest and most known.

On an industrial scale, the process often used is methane reform, which is the bombardment of natural gas or methane with steam at high temperature and pressure to separate carbon and hydrogen (BORLACE, 2020), which in the absence of carbon capture and sequestration (CCS) (TOTAL, 2018), can be released to nature, which today accounts for 1% of the CO2 emitted in nature. Nitrogen is obtained through fractional liquefaction or fractional distillation (LOPES DIAS, 2021).

Figure 24 – Haber-Bosch Ammonia production process

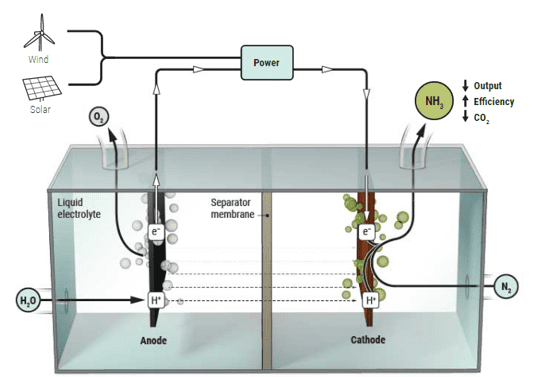

Water electrolysis is a more sustainable alternative for hydrogen generation. Through green electricity it is also possible to produce ammonia in a more sustainable way, Figure 25 demonstrates a simpler and greener model to produce ammonia (F.SERVICE, 2018).

Figure 25 – Production of Green Ammonia, through fuel cell

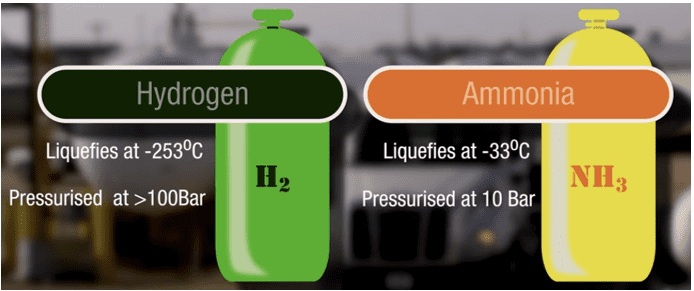

In the same way that hydrogen can be stored underground, it is also possible to store ammonia. Hydrogen needs temperatures of -253ºC to liquefy, and pressurized tanks for transport, while Ammonia liquefies at -10ºC, as seen in Figure 26, which makes Ammonia easier for transport and storage (F. SERVICE, 2018; BORLACE, 2020).

Figure 26 – Comparison of Hydrogen with Ammonia for transportation purposes

Ammonia is converted to hydrogen through the use of fuel cells without the need to use external energy sources. The Gas flows through catalysts where the separation of Hydrogen and Nitrogen takes place, which is released into the atmosphere, the hydrogen is then used in fuel cells that release electrons, producing electricity, by combining with oxygen (GENCELL, Ltd, 2019).

Figure 27 – Illustration of the molecular process of energy production through ammonia

Knowing that a volume of 58.905m3 has the potential to store 150 GWh of energy based on the volume of the aforementioned empirical reservoir 17,739,000 meters3, a reservoir with a depleted well, can store 45,172GWh of energy (INTERNATIONAL AGENCY, 2019).

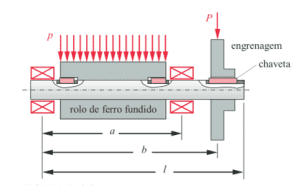

3.8 USE OF WELL STRUCTURE FOR POTENTIAL ENERGY STORAGE

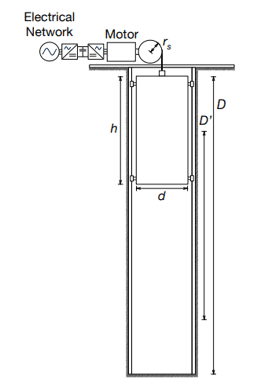

Gravity is a way to store energy through the use of weights that can be suspended, to store potential energy, and lowered to generate energy (MORSTYN et al., 2019).

Figure 28 – Illustration of the energy production process through gravity in wells

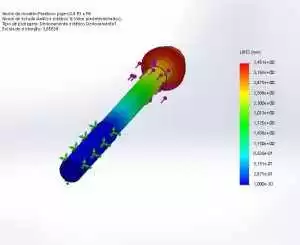

It is possible to estimate the energy capacity to be stored according to the following equation (MORSTYN et al., 2019):

Where the efficiency () of the system is considered 80% (MORSTYN et al., 2019), ‘m’ the mass will be considered 5 tons (5″ diameter lead charge, from the previously agreed empirical well, 35 meters high – density of 11340kg/m3), ´g´ is the force of attraction of the earth, approximately 10m/s2, and D´ is the usable depth of the well, here 1km, which results in 39.2 MJ or 11kWh.

The discharge speed of the system can be controlled according to the demand, of course the system can also be adapted to store different loads at the bottom of the well, which would allow the storage of more energy, in addition to working with loads of larger diameters. and dimensions depending on the need (GRAVITRICITY, 2020), existing oil wells can have their diameter increased, or they can be deepened with the use of reamers (THOMAS, 2001).

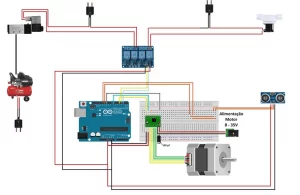

3.9 COMPRESSED AIR STORAGE IN THE RESERVOIR

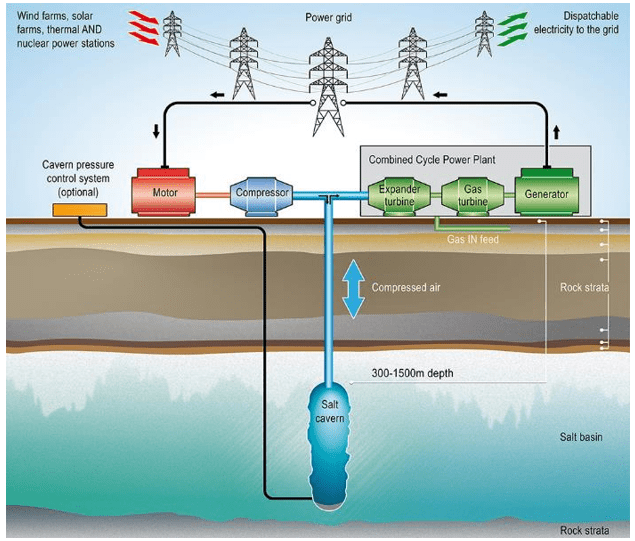

Considering the fact that the reservoir has a large volume, another way of accumulating and reusing energy from the reservoir would be through the pressurization of air, with the use of compressors in series of compressed air, where its release for the production of electric energy would be through turbines. in times of need, also known as CAES – Compressed Air Energy Storage (MENÉNDEZ; LORETO, 2019), as shown in Figure 29.

Figure 29 – Illustration of energy storage through compressed air

Table 4 demonstrates a comparison of air storage in different coal mines with some known volumes (MENÉNDEZ; LORETO, 2019), and, although studies are still needed to prove the use in oil reservoirs, the same analogy of the empirical reservoir of 17,739,000 meters3 and taking into account only the volume in table 4, a minimum storage capacity of 3.6GW can be estimated.

Table 4 – Comparison of air storage in different coal mines with some known volumes

In addition to the opportunity for air storage, there are also studies for the storage of pressurized water for later energy release (POWER TECHNOLOGY, 2016).

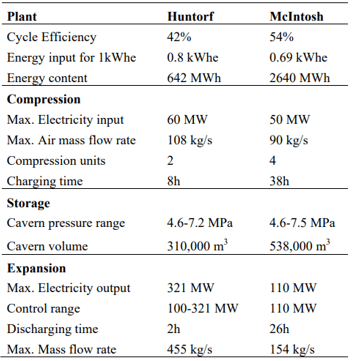

3.10 TIGHTNESS MONITORING

There are several possible ways through geophysics to ensure that the well conditions are stable and with good isolation, but it is also possible to create monitoring dynamics along the reservoir extension. Among the ways to guarantee the conditions of the well is the CBL (Cement Bonding Logging), and of the formations are the pressure tests (PEGASUS VERTEZ, Inc. 2021; THOMAS, 2001).

Figure 30 – Common problems in well cementing

Oil wells are completed using cemented steel casings to ensure insulation between formations and the inside of the well. The CBL method already mentioned is an indirect method used to ensure a good quality of cement. In cases of defects, it is possible to carry out an intervention operation to repair the poor cementation of the well and, in this way, guarantee that the work has solidified. There are cases where packers, tubular structures that lock onto linings, can be installed temporarily or permanently to ensure stability in certain areas of concern (THOMAS, 2001).

Figure 31 – Methane monitoring systems, fixed and by drones

Regarding the potential for leaks in other regions of the reservoir, it is possible to install fixed structures, use drones and also satellite monitoring, as shown in Figure 31 (BAKER HUGHES, 2021).

4. RESULTS AND DISCUSSION

Disengineering reengineering represents a sustainable potential for both the environment and the economy. The applications in oil and gas wells and reservoirs initially used for oil and gas exploration have several possibilities of use through this process.

Depending on the application to be used, there may be a need for intervention, and consequently an investment needs to be made to prepare the well for its final use. However, studies have demonstrated the advantages of taking advantage of a fully constructed structure.

The application will also determine the type of monitoring of potential emissions that needs to be structured to ensure zero impact to the environment, and in some cases special permits need to be developed.

The work focused on opportunities for recycling upper, lower and surface completion equipment for the reuse of steel, which contributes to the reduction of CO2 emissions and potential generation of carbon credits for the owner of the equipment, a market yet to be explored in Brazil, in addition to the opportunity to use it for carbon capture, which can be used to store carbon generated in Brazil, or, in other countries around the world, to store energy, with this potential, through the use of weights, for compressed air, hydrogen and even ammonia. Geothermal energy generation can also be an option depending on the geographic region where the well is located, and finally the storage of tailings from different sources, which nowadays occupy space in areas that can be used for other purposes. Table 5 shows some of the options discussed here.

Table 5 – 5W1H of options for unused wells

| What? | CO2 injection | Hydrogen or Ammonia Storage | Total or Partial Geothermal | Storage of Depleted Nuclear Fuel / Norm-Tenorm / Tailings | Potential Energy Storage | Compressed air |

| Who? | Oil and gas operator, or company operating carbon capture systems. | Hydrogen or ammonia producing company | Electricity generating company | Radioactive waste plants, companies responsible for the disposal of radioactive material or decontamination, nuclear plants. | Renewable energy generating companies or energy concessionaires. | Electricity generating company |

| How? | Pumping through compressors | Pumping through compressors | Use of the total or partial geothermal potential of a region, either through water pumping and steam return, or water pumping with heated water return that can later have its temperature a little higher with less use of energy for the generation of steam – use of steam in steam turbines. Another way would be to use hot water for other residential or industrial applications. | Storage in sealed and cemented capsules, later lowered into the well and finally cemented in the well. | Use of a weight system associated with an electric motor/generator. | Pumping through compressors and subsequent release for power generation |

| Where? | Depleted fields with good permeability and ample reservoir. | Depleted fields with good permeability and large reservoir close to hydrogen producing regions | High temperature wells. | Wells in regions where new drilling is not planned, which does not cross water tables and free from earthquakes. | Vertical wells, especially large diameter cases. | Depleted fields or not economically viable with good permeability and large reservoirs. |

| Why? | Return the CO2 produced as a result of burning fossil fuels for permanent storage in underground reservoirs. | Proximity, space utilization, storage cost reduction | Take advantage of the geothermal potential of some wells and thus avoid the use of other forms of energy to produce hot water. | Take advantage of the space in wells that can be kilometers deep and thus guarantee a permanent storage of radioactive material without posing a risk to society;

Greater availability of surface space for other uses. |

Accumulate potential energy to release in times of scarcity | Accumulate energy and release it in times of need |

| Where? | Whenever it is necessary to store CO2. The well does not always need to be close to the capture region, transport can be by pipeline, trucks, trains or ships. | When the reservoir ends its economic life and there are conditions for the production of hydrogen nearby. | At the end of the economic production of the oil field | At the end of the useful life of nuclear fuel or radioactive waste. | During peaks in electricity production | During peaks in electricity production |

Source: Author

5. FINAL CONSIDERATIONS

The end of the use of the oil well, or the temporary interruption of its use, must not represent the end of its value to society or stand still without generating opportunities, its economic value may be even greater depending on the intended use, and depending on the application, with a small CAPEX and a minimum OPEX, one can generate profit for many years or opportunities to vacate an area that was previously destined for tailings, for example.

Disengineering should not be the end or be seen as a penalty at the end of depreciating the use of an enterprise or asset, but rather it should represent an opportunity to do more business through reengineering.

REFERENCES

ACTIS, A. O método Gás- Lift. Disponível em: Campos Marginais de Petróleo: <<http://camposmarginais.blogspot.com/2012/03/o-metodo-gas-lift.html>> . 2012

AGENCIA NACIONAL DO PETRÓLEO. Resolução ANP Nº 699 DE 06/09/2017. Disponível em: <<ANP.GOV: https://view.officeapps.live.com/op/view.aspx?src=http%3A%2F%2Fwww.anp.gov.br%2Fimages%2FConsultas_publicas%2FConcluidas%2F2017%2Fn_06%2FResolucao_pocos.docx&wdOrigin=BROWSELINK>>. 2017.

AGENCIA NACIONAL DO PETRÓLEO. Opportunities in the Brazilian Oil & Gas Industry. Fonte: Agencia Nacional do Petróleo: <<http://www.anp.gov.br/images/publicacoes/Livreto_Upstream_2018-I.pdf>>. 2018

AGÊNCIA EPBR. Monitor da Perfuração. Disponível em: epbr: <<https://epbr.com.br/monitor-da-perfuracao/consulta-de-pocos-perfurados>>. 2021

AGÊNCIA NACIONAL DO PETRÓLEO, Gás Natural e Biocombustíveis. Acervo de dados. Disponível em: <<gov.br: https://www.gov.br/anp/pt-br/assuntos/exploracao-e-producao-de-oleo-e-gas/dados-tecnicos/acervo-de-dados>>. 2021

AREATECNOLOGIA. Turbina de Vapor. Disponível em: Areatecnologia: <<https://www.areatecnologia.com/mecanismos/turbina-de-vapor.html>>. 2021

BAKER HUGHES. Emissions management. Disponível em: Baker Hughes: <<https://www.bakerhughes.com/emissions-management>>. 2021

BORLACE, D. Hydrogen energy storage in AMMONIA: Fantastic future or fossil fuel scam? Disponível em: Youtube: <<https://www.youtube.com/watch?v=5Y_2Z_VwFNc>>. 2020

BraCKE, G., CHARLIER, F., LIEBSCHER, A., R. SCHILLING, F., & RÖCKEL, T. About the Possibility of Disposal of HLRW in Deep Boreholes in Germany. Geosciences, 1-17. 2017

CASTRO FARIA, M. Estrutura geológica e mineração. Disponível em: Educação Globo: <<http://educacao.globo.com/geografia/assunto/geografia-fisica/estrutura-geologica-e-mineracao.html>>. 2013

CBIE. O QUE SÃO OS CUSTOS DE EXTRAÇÃO DO PETRÓLEO? Disponível em: CBIE: <<https://cbie.com.br/artigos/o-que-sao-os-custos-de-extracao-do-petroleo/>>. 2019

CEPEMAR. Atividade de Produção e Escoamento de Petróleo e Gás Natural do Campo de Golfinho, Bacia do Espírito Santo. Disponível em: Instituto de Meio Ambiente e Recursos Hidricos do Estado do Espirito Santo: <<https://iema.es.gov.br/Media/iema/Downloads/RIMAS/RIMAS_2005/Produ%C3%A7%C3%A3o%20e%20escoamento%20-%20Campo%20de%20golfinho%20ES.pdf>>. 2005

CONOCOPHILLIPS. The Life Cycle of a Well – ConocoPhillips. Disponível em: YouTube: <<https://www.youtube.com/watch?v=0r4J34FEsTk>>. 2015

CONSELHO DE PROMOÇÃO DA FINLÂNDIA. Os resíduos nucleares descansarão em paz. Disponível em: This is Finland: <<https://finland.fi/pt/vida-amp-sociedade/os-residuos-nucleares-descansarao-em-paz/>>. 2021

DA SILVA, M., BARILLAS, J., & DUTRA JR., T. Estudo Paramétrico da Injeção de Polímeros em Reservatórios de Petróleo. XX Congresso Brasileiro de Engenharia Química, 1-8. 2014

DUARTE, L., & CATAIA, M. Transformações espaciais da exploração e produção de petróleo no território brasileiro: a distribuição dos poços perfurados (1922-2015). KOSMOS, 7-10. 2019

DW Planet A. Can carbon capture ACTUALLY work? Disponível em: YouTube: <<https://www.youtube.com/watch?v=JHs-eWHb16g&t=105s>>. 2021

E. V. LOPES, A., & ASSUMPÇÃO, M. Uma breve conversa sobre a disciplina Sísmica I – Primeira Aula. Disponível em: Instituto de Astronomia, Geofísica e Ciências Atmosféricas – USP: <<https://www.iag.usp.br/~marcelo/agg232info/Power%20Points%20das%20aulas/aula01-Introducao_ao_Curso.pdf>>. 2010

ELECTRO ENERSOL. Geotermia. Fonte: Electro Enersol: <<https://www.electroenersol.com/?p=44>>. 2011

F. SERVICE, R. Ammonia—a renewable fuel made from sun, air, and water—could power the globe without carbon. Disponível em: Science: <<https://www.science.org/news/2018/07/ammonia-renewable-fuel-made-sun-air-and-water-could-power-globe-without-carbon>>. 2018

GENCELL LTD. Ammonia: The Next Big Thing in Energy Production – GenCell. Disponível em: Youtube: <<https://www.youtube.com/watch?v=drdDt1ski1I>>. 2019

GOMES, A., KOVALESKI, J., SCHMANECH TRAMONTIN, A., & SCHMANECH TRAMONTIN, A. Reengenharia: Revisando os velhos conceitos ainda atuais. Gestão da Produção: Organização e Planejamento, 218-225. 2005

GOVERNMENT OF THE REPUBLIC OF TRINDAD AND TOBAGO. Carbon Capture Utilization and Storage (CCUS). Disponível em: Ministry of Energy and Energy Industries: <<https://www.energy.gov.tt/carbon-capture-utilization-and-storage-ccus/>>. 2021

GOVERNO DE SÃO PAULO. Tratamento e destinação. Disponível em: CETESB: <<https://cetesb.sp.gov.br/emergencias-quimicas/tipos-de-acidentes/vazamentos-de-oleo/acoes-de-resposta/residuos-oleosos/tratamento-e-destinacao/>>. 2021

GRAVITRICITY. Latest Gravitricity Explainer Extended Animation Spring 2020. Disponível em: Youtube: <<https://www.youtube.com/watch?v=meFkbADJq28>>. 2020

INTERNATIONAL ENERGY AGENCY. The Future of Hydrogen – Seizing today’s opportunities. Disponível em: IEA: <<https://iea.blob.core.windows.net/assets/9e3a3493-b9a6-4b7d-b499-7ca48e357561/The_Future_of_Hydrogen.pdf>>. 2019

IVANOV, K., BELOVSKI, I., & ALEKSANDROV, A. Research and Analysis of the Electromotive Voltage Generated by Seebeck and Peltier Modules. 12th National Conference with International Participation “Electronica 2021”, 1-4. 2021

JÁCOME, I. Após um ano, petrolífera aumenta em 30% produção de campos vendidos pela Petrobras no RN. Disponível em: G1: <<https://g1.globo.com/rn/rio-grande-do-norte/noticia/2021/06/18/apos-um-ano-petrolifera-aumenta-em-30percent-producao-de-campos-vendidos-pela-petrobras-no-rn.ghtml>>. 2021

KÜHN, M., STREIBEL, M., NAKATEN, N., & KEMPKA, T. Integrated Underground Gas Storage of CO2 and CH4 to Decarbonise the “Power-to-gas-to-gas-to-power” Technology. ScienceDirect, 9-15. 2014

LINCERADIO. O que é Descontaminação NORM/TENORM? Disponível em: LINCERADIO: <<https://linceradio.com.br/o-que-e/o-que-e-descontaminacao-norm-tenorm/>>. 2021

LOPES DIAS, D. Nitrogênio. Disponível em: Brasil Escola: <<https://brasilescola.uol.com.br/quimica/nitrogenio.htm>>. 2021

MATLAK AL-HAJERI, M., AL SAEED, M., DERKS, J., FUCHS, T., HANTSCHEL, T., KAUERAUF, A., PETERS, K. Basin and Petroleum Modelling. Oilfield Review, 14-29. 2009

MENÉNDEZ, J., & LOREDO, J. Compressed Air Energy Storage plants in abandoned underground mines: Preliminary analysis and potential. IAPE ’19, 1-4. 2019

MODEKURTI, S., ESLICKB, J., OMELLB, B., BHATTACHARYYA, D., C. MILLERB, D., & E.ZITNEYC, S. Design, dynamic modeling, and control of a multistage CO2 compression system. International Journal of Greenhouse Gas Control, 31-45. 2017

MORSTYN, T., CHILCOTT, M., & D. MCCULLOCH, M. Gravity Energy Storage with Suspended Weights for Abandoned Mine Shafts. Applied Energy, 1-7. 2019

PEGASUS VERTEX, INC. Common Well Cementing Problems. Disponível em: Pvisoftware: <<https://www.pvisoftware.com/infographics/Common_Well_Cementing_Problems.PDF>>. 2021

PETROBRAS. Plano de Desenvolvimento Aprovado Reunião de Diretoria nº 827 de 09/12/2015 Resolução nº 1001/2015. Disponível em: Agência Nacional do Petróleo: <<http://www.anp.gov.br/images/planos_desenvolvimento/Marlim.pdf>>.2015

PETROSKILLS. Introduction to Artificial Lift. Disponível em: Petroskills: <<https://www.petroskills.com/blog/entry/00_totm/sept17-sub-totm-artificial-lift?page=5#.YUXtTp1KjIU>>. 2017

POWER TECHNOLOGY. Could depleted oil wells be the next step in energy storage? Disponível em: Power Technology: << https://www.power-technology.com/features/featurecould-depleted-oil-wells-be-the-next-step-in-energy-storage-5680002/>>. 2016

PUC-RIO. Maxwell. Fonte: PUC-Rio: <<https://www.maxwell.vrac.puc-rio.br/22966/22966_3.PDF>>.2011

ROSA, A. J. Engenharia de Reservatório de Petróleo. Rio de Janeiro: Interciência. 2006

SÁNCHEZ, L. Desengenharia. O passivo ambiental na desativação de empreendimentos industriais. São Paulo: EdUSP/FAPESP. 2001

SANDIA NATIONAL LABORATORIES. Economic Analysis of Large-Scale Hydrogen Storage for Renewable Utility Applications. Albuquerque, New Mexico 87185 and Livermore, California 94550: SANDIA REPORT. 2011

SANSONE, E. Permeabilidade das Rochas. Disponível em: edisciplinas.usp.br: <<https://edisciplinas.usp.br/pluginfile.php/1678305/mod_resource/content/1/07%20-%20PMI1673%20-%202014%20-%20Permeabilidade.pdf>>. 2015

SHEN, Z.-G., TIAN, L.-L., & LIU, X. Automotive exhaust thermoelectric generators: Current status, challenges and future prospects. Energy Conversion and Management, 1138-1173. 2019

SHULMAN, G. LOW TEMPERATURE FLASHED STEAM POWER GENERATION. Disponível em: <<https://www.geothermal-energy.org/: https://www.geothermal-energy.org/pdf/IGAstandard/WGC/1995/3-shulman.pdf>>. 1995

SILVA, M., RIBEIRO, J., CARMO, J., GONCALVES, L., & CORREIA, J. Thin-films for Thermoelectric Applications. University of Minho, 1-23. 2013

SMITH, F. Hazardous Waste Disposal And Cleaning. Disponível em: SlideShare: https://www.slideshare.net/mohammedashique5/hazardous-waste-disposal-and-cleaning-biochemical-and-nuclear-wastes>>. 2018

SORENSEN, E. Canada’s nuclear waste to be buried in deep underground repository. Disponível em: Global News: <<https://globalnews.ca/news/5329835/canadas-nuclear-waste-to-be-buried-in-deep-underground-repository/>>. 2019

STORELECTRIC. The Storelectric Technology. Disponível em: Storelectric: <<https://www.storelectric.com/technology/>>. 2021

SWAROWSKI ARBOIT, N., DECEZARO, S., MELLO DO AMARAL, G., LIBERALESSO, T., MICHAEL MAYER, V., & DA CUNHA KEMERICH, P. Potencialidade de utilização da energia geotérmica no brasil – uma revisão de literatura. Revista do Departamento de Geografia – USP, Volume 26, 155-168. 2013

THOMAS, J. Fundamentos de Engenharia de Petróleo. Rio de Janeiro: Interciência. 2001

TOTAL. Total – What is CCUS? Disponível em: YouTube: https://www.youtube.com/watch?v=HSvWrjviqZM>>. 2018

US ENERGY INFORMATION ADMISTRATION. Nuclear explained: Nuclear power and the environment. Disponível em: US Energy Information Admistration: <<https://www.eia.gov/energyexplained/nuclear/nuclear-power-and-the-environment.php>>. 2020

VISSER, W. Why metals should be recycled, not mined. Disponível em: The Guardian: <<https://www.theguardian.com/sustainable-business/2014/nov/05/metals-recycled-mine-extractive-business>>. 2014

ZHANG, J., GUO, J., LI, Y., & SUN, Z. 3D-Basin Modeling of the Changling Depression, NE China: Exploring Petroleum Evolution in Deep Tight Sandstone Reservoirs. Energies, 1-27. 2019

ZHOU, W., YAMAMOTO, K., MIURA, A., IGUCHI , R., MIURA, Y., UCHIDA, K.-I., & SAKURABA, Y. Seebeck-driven transverse thermoelectric generation. Nature Materials, 463-467. 2021

APPENDIX – FOOTNOTE

3. Brazilian National Petroleum Agency.

4. NORM and TENORM are naturally occurring radioactive materials.

[1] Graduated in Petroleum Engineering from Universidade Estácio de Sá (UNESA), and Graduated in Mechanical Technology with emphasis in Industrial Automation from CEFET/RJ. Master in Mechanical Engineering from the University of Taubaté (UNITAU), MBA in Business Management from Fundação Getúlio Vargas (FGV), MBA in Project Management from the Foundation supporting CEFET/RJ, Specialist in Occupational Safety Engineering from Universidade Candido Mendes (UCAM), Specialist in Petroleum Engineering from Universidade Estácio de Sá (UNESA) and certified Radioprotection Supervisor by CNEN. ORCID: 0000-0002-6647-3914.

[2] Advisor. Graduated in Architecture and Urbanism from the University of Taubaté, UNITAU, with a postgraduate degree in Marketing Management and Occupational Safety Engineering from the Polytechnic School of Pernambuco. Master in Regional Development Management from UNITAU and PhD in Production Engineering from Escola Politécnica da USP. ORCID: 0000-0001-8082-5763.

Sent: April, 2022.

Approved: July, 2022.