ORIGINAL ARTICLE

OLIVEIRA, Rodrigo Suzano de [1]

OLIVEIRA, Rodrigo Suzano de. Development of a methodology for asset integrity management in Universities and Research Centers. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year 09, Ed. 01, Vol. 02, pp. 133-147. January 2024. ISSN: 2448-0959, Acess link: https://www.nucleodoconhecimento.com.br/engineering-mechanical-engineering/integrity-management, DOI: 10.32749/nucleodoconhecimento.com.br/engineering-mechanical-engineering/integrity-management

ABSTRACT

This article describes the application of a differentiated methodology that I developed to enhance and facilitate asset management work in renowned universities and research centers. Frequently, important scientific studies and research are interrupted or wasted due to unexpected failures in equipment and infrastructure systems provided by universities and research centers for researchers’ use. To address this issue, this methodology incorporates structured concepts and practices commonly employed in the field of asset integrity. These are uniquely integrated into comprehensive engineering assessment reports developed over several years during my fieldwork in various countries. This integration occurs within a computerized maintenance management system. The ultimate goal of this process is to maximize the reliability and performance of critical systems and equipment used in the infrastructure and conduct of highly relevant research at the national and international levels. Through case studies conducted at two major universities in the United States, the efficiency of this innovative methodology was analyzed quantitatively and qualitatively. As presented in this article, the main results obtained include a reduction in the number of unplanned repairs or shutdowns, improved quality and efficiency of maintenance programs, increased reliability and lifespan of critical research equipment and systems, an increase in the number of assets with an appropriate maintenance plan, and the enhancement of computerized maintenance management systems used by these institutions. These results translate into faster completion of scientific studies and research with more reliable data.

Keywords: Asset Integrity, Maintenance, Reliability, Universities, Research Centers.

1. INTRODUCTION

Leading universities and renowned research centers with global recognition have been increasingly developing studies and research over the years focused on improving the well-being and quality of life for people. As the years have passed, such studies and research have come to require increasingly modern and effective systems and equipment capable of meeting their new needs. In this context, many universities and research centers have recently started looking at the need for improvement in their basic and advanced infrastructure systems in a differentiated way.

For instance, the management of equipment performance data and information, which was previously done through spreadsheets and basic data collection systems, now faces the need for increasingly sophisticated and automated management systems. The new methodology to be presented in this article has been enhanced with a focus on this current context of modernization and sophistication in the management of asset integrity in academic and scientific research environments. Its differentiating factor lies in the use of unique results obtained through engineering assessments conducted over many years, forming the information foundation to be integrated into an automated management system along with concepts and tools used in asset integrity management.

Basic traditional concepts and innovative concepts that, when integrated into computerized maintenance management systems, contribute to the development of this new methodology will be presented next. Therefore, it can be stated that this methodology is supported by three pillars: the unique results of engineering assessment reports that I have developed over years of work in dozens of industrial facilities around the world, the key concepts commonly used in asset integrity management, and the integrated computerized maintenance management system.

Practical examples of the use of this methodology and real results obtained at two of the world’s largest universities, MIT and Harvard, will be presented to illustrate the importance and scope of this work.

2. CONCEPTS USED IN THE DEVELOPMENT OF THE METHODOLOGY

This intriguing methodology for asset integrity management applied to universities and research centers is based on concepts of maintenance engineering and asset management tools, along with dozens of unique engineering assessment reports produced over more than 15 years of fieldwork focused on maintenance and performance of equipment and infrastructure systems. The following are the concepts and tools that will be presented.

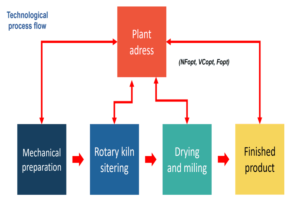

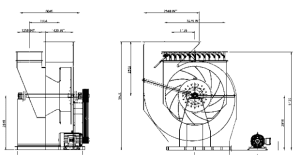

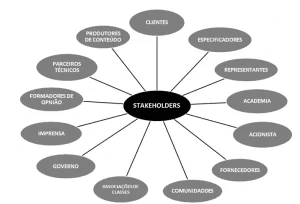

2.1 TECHNICAL HIERARCHY

The analysis of the technical hierarchy of equipment and systems is the first step to be performed in this methodology. Its objective is to identify the main assets of an installation and which components and equipment function as a fundamental part of that asset. It is a structural hierarchy that typically encompasses 8 sequential levels (from the highest to the lowest): plant, area, subarea, line, machine, assembly, equipment, component (Modular, 2022). For example, in certain research environments, temperature and pressure control systems are critical for the progress and final outcome of the work. Such systems have the main asset as the cooling and air supply system for the laboratories. The main components and equipment that are part of this system include air filters, temperature and pressure sensors, electric motors, variable speed drives, fans, and humidity controllers. In this scenario, the cooling and air supply system is what we call the main asset or parent asset, and the components and equipment are the secondary assets or child assets. It is important to emphasize that such analysis must be done individually for each identified asset in the installation to define the system to which it belongs and what its technical hierarchy would be.

The next step is the consequence classification, which is associated with the criticality of each asset.

2.2 CONSEQUENCE CLASSIFICATION

Once the technical hierarchy stage is completed, and all assets are allocated within the defined hierarchical structure, the task of identifying the criticality of each asset based on its systemic functionalities begins. This process is carried out through the consequence classification process.

In consequence classification, the first step is to analyze the impact that a failure in an asset could have on the operation of the facility. In the case of universities and research centers, this refers to the impact that a failure of that asset would have on research development and the academic environment as a whole. This analysis is based on the severity of the failure (Trout, [n.d.]).

After assessing severity, a second analysis is conducted regarding the probability of this failure occurring. This analysis takes into account the existence of redundant systems and equipment, such as portable air conditioners that could compensate for the failure of a central cooling system, as well as the availability of spare parts, which have the potential to reduce or even eliminate such occurrences. Finally, once the consequences and probabilities are determined, the degree of consequence classification for each asset is defined. The higher or more critical the consequences and the greater the probabilities of failure occurrence, the higher the degree of classification (Trout, [n.d.]).

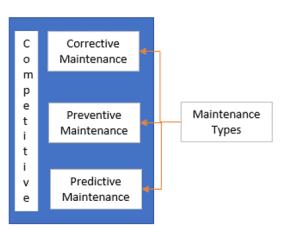

2.3 MAINTENANCE STRATEGY

This is the third step used in asset integrity management. At this stage, the results of consequence classification and the technical hierarchy of each asset are analyzed to define the most suitable maintenance strategy for a particular equipment or system. The goal now is to define ideas, tactics, indicators, schedule, and resources needed to keep the assets operating at their maximum capacity and reliably. The most common maintenance strategies are preventive maintenance, predictive maintenance, condition-based maintenance, and run-to-failure maintenance (IBM, 2022). In an academic or research environment, for example, run-to-failure maintenance is predominantly applied, and in some cases, preventive maintenance, although predictive and condition-based maintenance are typically the ones that bring more satisfactory results from an equipment performance perspective.

2.4 SPARE PARTS MANAGEMENT

After defining which maintenance strategy will be adopted for each asset, it is time to determine how the material necessary for such maintenance will be managed. This is a crucial analysis that will directly influence the budget applied to general asset management and the management of available space for material, equipment, and parts storage. A commonly employed solution to assist organizations with limited physical space is to transfer spare parts management to suppliers or partner companies. The main objective of this step is simply to ensure that materials, equipment, and spare parts will be available when required and promptly in the event of failures, so as not to hinder campus operations and the development of critical research.

During this critical step, the criticality of each asset for the continuity of operations, the type of maintenance strategy defined, and the time required to obtain a new piece of equipment or spare part to address potential infrastructure failures are analyzed. For example, in the case of a breakdown of an electric motor that affects an entire cooling system, the criticality would likely be severe, with the potential to disrupt important operations and research, especially if it is decided that such a motor will operate until it breaks without any preventive or predictive maintenance to help prevent its failure. Therefore, this would be a scenario where having a spare motor with immediate availability becomes highly advisable (IBM [n.d.]a).

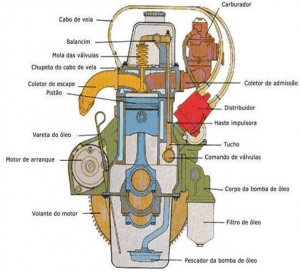

2.5 MAINTENANCE CONCEPTS

This is considered an optional stage within this asset integrity management methodology, but highly recommended. In this stage, equipment or similar systems are identified, and general maintenance concepts are created based on manufacturers’ recommendations, industry best practices, experts’ previous experiences, and mandatory regulatory standards (ACQ, 2021). For example, a group of equipment would be the electric motors group, and within this group, maintenance concepts related to direct current electric motors, low-power electric motors, high-power electric motors, and alternating current motors can be created. The concepts should outline the step-by-step procedures for maintenance of that equipment or system.

After the creation of maintenance concepts, they will be incorporated into the maintenance plans of the assets within computerized systems with the ultimate goal of guiding maintenance technicians during the execution of their field activities and assisting in the management of the necessary workforce to maintain operations efficiently and reliably as much as possible (ACQ, 2021).

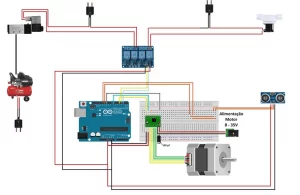

2.6 COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEMS

Computerized Maintenance Management Systems (CMMS) are the tools that integrate all the steps within the asset management process, and the most well-known ones in the market include SAP, MAXIMO, MANAGERPLUS, FIIX, and EMANT. These systems are usually divided into various modules and require specific training for their users (IBM, [n.d.]c). They store information about assets such as name, identification, installation year, useful life, description, function, and many others. Moreover, this is the tool that integrates the work done in all previous stages. Therefore, returning to the example of the electric motor, the database would contain the motor’s description and characteristics, as well as who its parent asset is, how critical it is to the installation, and what strategies will be adopted for its maintenance and spare parts. Additionally, it serves as a work control system for the personnel responsible for performing maintenance in the field, where historical maintenance data and associated costs are stored.

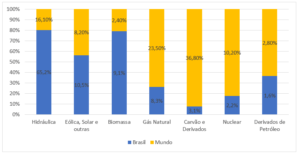

3. TRADITIONAL MODEL OF ASSET INTEGRITY MANAGEMENT

Asset integrity management is often well developed in cutting-edge industries such as the oil and technology sectors. It is quite common to find companies in these areas, such as Petrobras, Equinor, Shell, among others, investing significantly in equipment maintenance and asset management. Data from the Poder360 website (2022) shows that in 2021, for example, Petrobras invested over R$2.3 billion in this area.

On the other hand, the reality in the education sector is entirely different. Unfortunately, universities and research centers focus on acquiring equipment for their studies and research but do not invest in maintaining these assets. As addressed by Lima and Castilho (2006) in their study on the aspects of maintenance of scientific equipment at the University of Brasília, maintenance management at UNB is inefficient and results in a high rate of unavailability of basic infrastructure and equipment used in teaching, research, and support laboratories, leading to a decrease in the operational capacity of the institution and a high level of dissatisfaction among researchers and scholars who depend on these equipment and systems to carry out their work. Lima and Castilho (2006) also note that ‘an organized maintenance structure requires investments, efforts for rationalization, and the constant updating of technical personnel. These aspects collide with the administrative view interested in short-term results and immediate problem-solving, not seeing the significant economic benefits resulting from increased equipment utilization time and the reduction of scientific and academic losses.’

In 2023, the Federal University of Mato Grosso do Sul Foundation opened a call for financial support for research, extension, or innovation with a focus on the installation and/or maintenance of equipment for laboratories. Only items related to expenses for installation or preventive or corrective maintenance of equipment would be funded in this call (UFMS, 2023). This approach highlights the inadequacy of the methodology used by this university and the complete absence of an integrated system that truly addresses asset integrity management.

The developed methodology to be discussed in this article aims to fill this gap in asset integrity management, especially concerning equipment and infrastructure systems used in universities and research centers in Brazil and around the world.

4. THE METHODOLOGY AND ITS STAGES

Initially, this methodology was developed and applied in oil production units in the energy, oil, and gas industries. Engineering data related to maintenance and asset integrity were compiled from projects executed worldwide on engineering works in ships and platforms located in multiple countries, as well as manufacturing petrochemical plants in Brazil and abroad.

Over these years, significant results were achieved using this methodology, such as: increased manufacturing capacity and adaptation of ships in mega shipyards located in Singapore and South Korea, improved reliability and performance of industrial equipment used on three drilling platforms and the oil production ship in the Peregrino field in Brazil, and complete technical adaptation of equipment in explosive areas used in the fleet of FPSOs of one of the largest oil and gas producers in Brazil and the world.

Since 2019, an updated version of this methodology has been developed with a special focus on academic environments in top-tier universities and research centers of national and international relevance. One of the institutions where this methodology was applied is the Massachusetts Institute of Technology (MIT) in Cambridge, United States.

As defined on its official website, MIT is a ‘private world-class technology research institute, founded to accelerate the country’s industrial revolution. MIT engineers and researchers have invented fundamental technologies, launched new industries, and created millions of jobs in the United States. At the same time, MIT is deeply global. Its community has tremendous strength as a magnet for talent from around the world. Through teaching, research, and innovation, MIT’s exceptional community pursues its mission to serve the nation and the world. Research at MIT aims to develop innovative solutions to the world’s most daunting challenges, from meeting tomorrow’s energy needs to improving cancer therapies’ (MIT, [n.d.]).

In 2019, MIT decided to heavily invest in the management of its infrastructure assets, especially those used in its most critical research. The asset management methodology in question was widely applied at this institution to enhance the reliability and performance of systems and equipment critical to its operations. The following steps will discuss how this methodology works in practice.

The first step in developing and implementing this methodology within MIT was to accurately catalog all assets in operation at the institution. This information was added to the SAP database, which is the computerized maintenance management system used by MIT. This process took several months to complete due to the large number of assets on the campus.

The second stage involved identifying the main infrastructure systems and establishing the technical hierarchy of assets related to these systems. This stage was completed in a month of work and involved about 15 thousand assets.

The third stage comprised the consequence classification of each of these assets. In this stage, the levels of failure criticality were analyzed concerning their impact on research and human life protection. Next, the probabilities of these failures occurring were analyzed based on equipment condition, service life, and the existence (or lack thereof) of redundant equipment.

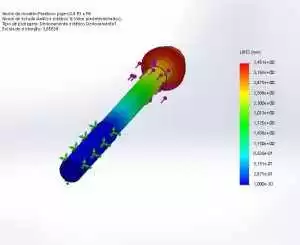

The fourth stage focused on defining the maintenance strategy. This was the most time-consuming stage of all due to the fact that only 15% of the assets had any information available in the database used by the institution. In this stage, after concluding the definition of the strategies to be adopted, over a thousand maintenance plans were created in SAP to manage scheduled interventions. It is during the creation or updating of these maintenance plans that the methodology takes shape and shows its unique character. At this point, the unique results from engineering assessments obtained over several years worldwide are integrated into management tools through the computerized maintenance management system. It is worth noting that MIT also chose to include, as part of the methodology implementation, real-time monitoring systems to enable even more effective asset management. Similarly, these monitoring systems were integrated into management tools through the computerized maintenance management system, aiding in the performance control of assets.

Finally, the spare parts analysis was completed, resulting in the creation of an exclusive warehouse for the storage of maintenance parts and equipment, and the addition of maintenance concepts to the asset management database.

5. RESULTS OF THE METHODOLOGY APPLICATION AND NEXT STEPS

Over a span of two years, several parameters related to the performance of critical equipment were analyzed at MIT to evaluate the results of applying this methodology.

The main findings were:

- 6% reduction in the number of unplanned repairs in infrastructure systems used for scientific research;

- Improvement in the quality and efficiency of maintenance programs across the entire institute’s infrastructure;

- Increased reliability and lifespan of critical equipment and systems used in laboratories;

- The percentage of assets with an adequate maintenance plan rose from 15% to nearly 100% within a year;

- Drastic enhancement of the computerized maintenance management system.

Such results demonstrate the efficiency of this new methodology and indicate its applicability in similar environments and institutions worldwide.

Currently, a second version of this methodology has been implemented since 2022 at Harvard University, specifically at its Medical School in Boston, also in the United States.

At Harvard Medical School, the computerized maintenance management system used is Maximo (Harvard, [n.d.]). This system has similar functions to the SAP system used by MIT concerning asset management. Like MIT, Harvard Medical School also recently decided to invest in the modernization and improvement of its asset management, aiming to ensure the efficient performance and realization of medical research. The implementation stages of the methodology at Harvard remain the same, but the School of Medicine’s database already contains a significant portion of maintenance plans used on campus. Therefore, once the hierarchy, classification, and strategies stages are completed, it will not be necessary to create maintenance plans from scratch but rather to update them with the findings.

An additional stage is under consideration to be implemented at the end of this process for continuous improvement of this new asset integrity management system. This stage involves failure codes (failure code). In this phase, equipment or system failures, their causes, and remedial actions will be analyzed, cataloged, and integrated into the asset integrity management system with the primary goal of making management more efficient (IBM, [n.d.]b). Since this stage is still in development, its implementation and results will be discussed in the future.

Preliminary results from using this new methodology at Harvard are promising, and a reduction in the number of unplanned repairs and increased satisfaction among professors and researchers regarding the performance of critical equipment and systems for their research have already been identified.

As the main outcome, the work done so far has greatly contributed to safeguarding important national and international research and increasing the capacity for simultaneous research, especially in the Microbiology department at the School of Medicine.

With the completion of the implementation of this new asset integrity management methodology at Harvard, it is expected that the results in the field of medical research will be as prominent as those seen at MIT, significantly assisting in concluding research that directly impacts the health and well-being of thousands of people around the world.

6. CONCLUSION

Based on this article, it is possible to understand the stages, processes, and technical material involved in this unique methodology used in asset integrity management within renowned universities and research centers, such as MIT and Harvard, known worldwide for their excellence in research and education.

The presented results confirm the added value and benefits when using such a methodology to assist in managing critical infrastructure assets, suggesting that other institutions with similar objectives could also benefit widely from this project, especially in Brazil, where existing traditional maintenance management methodologies are inefficient.

As verified, the main goal of this original methodology, to enhance and facilitate asset management in universities and research centers, was successfully achieved in the project executed at the Massachusetts Institute of Technology (MIT). This methodology was able to increase the reliability, lifespan, and performance of equipment and infrastructure systems used in important scientific studies and research, preventing them from being interrupted or wasted due to unexpected failures.

Additional work with the same methodology is being carried out at the Harvard Medical School, indicating promising results similar to those achieved at MIT. Once concluded, this second implementation project of the methodology can also serve as a reference in Brazil and worldwide, aiding scientific research in various fields of study.

This methodology represents over 15 years of accumulated knowledge but is constantly evolving, where new opportunities will be considered to increasingly make it unique and of extraordinary value, focusing on practical benefits for social well-being.

REFERENCES

ACQ. Maintenance Concept Plan. AcqNotes, 2021. Disponível em: https://acqnotes.com/acqnote/careerfields/maintenance-concept-plan. Acesso em : 26 jan. 2024.

LIMA, F. A.; CASTILHO, J. C. N. Aspectos da Manutenção dos Equipamentos Científicos na Universidade de Brasília. 2006. Dissertação (Especialista em Desenvolvimento Gerencial) – Faculdade de Economia, Administração, Contabilbidade e Ciências da Informação e Documentação – Universidade de Brasília. Brasília-DF, 2006.

HARVARD-HMS: Who We Are. Harvard Medical School, [s.d.]. Disponível em: https://meded.hms.harvard.edu/admissions-who-we-are#:~:text=A%20Harvard%20Medical%20School%20education,continues%20to%20set%20the%20standard. 2023. Acesso em: 26 jan. 2024.

IBM. List Failure Codes. IBM, 2022. Disponível em: https://www.ibm.com/docs/en/cdfsp/7.6.1?topic=problems-list-failure-codes.

IBM. O que é estratégia de manutenção? IBM, [s.d.]. Disponível em: https://www.ibm.com/br-pt/topics/maintenance-strategy. Acesso em: 26 jan. 2024.

IBM. O que é manutenção centrada na confiabilidade? IBM, [s.d.]. Disponível em: https://www.ibm.com/br-pt/topics/reliability-centered-maintenance#:~:text=Manuten%C3%A7%C3%A3o%20centrada%20na%20confiabilidade%20(RCM,operando%20em%20um%20n%C3%ADvel%20ideal. Acesso em: 26 jan. 2024.

IBM. What is a computerized maintenance management system (CMMS)? IBM, [s.d.]. Disponível em: https://www.ibm.com/topics/what-is-a-cmms. Acesso em: 26 jan. 2024.

MIT. About MIT. Massachusetts Institute of Technology, [s.d.]. Disponível em: https://www.mit.edu/about/. Acesso em: 26 jan. 2024.

MODULAR. Classificação de Equipamentos ou Ativos: O que é e como fazer? Modular Cursos, 2022. Disponível em: https://modularcursos.com.br/classificacao-de-equipamentos-ou-ativos/. Acesso em: 26 jan. 2024.

PODER 360. Petrobras bate recorde de gasto com manutenção de refinarias. Poder360, 2022. Disponível em: https://www.poder360.com.br/economia/petrobras-bate-recorde-de-gasto-com-manutencao-de-refinarias/. Acesso em: 26 jan. 2024.

TROUT, J. Criticality Analysis: What It Is and Why It’s Important. ReliablePlant, [s.d.]. Disponível em: https://www.reliableplant.com/criticality-analysis-31830. Acesso em: 26 jan. 2024.

UFMS: Projetos de pesquisa serão beneficiados com instalação e manutenção de equipamentos em laboratórios. Fundação Universidade Federal de Mato Grosso do Sul, 2023.

[1] MBA in Project Management from Fundação Getúlio Vargas in Rio de Janeiro, Postgraduate degree in Occupational Safety Engineering from Universidade Candido Mendes in Campos dos Goytacazes, Bachelor’s degree in Electrical Engineering with a focus on Automation from Universidade Santa Úrsula in Rio de Janeiro. ORCID: 0009-0007-7812-0538. Currículo Lattes: http://lattes.cnpq.br/3997154402798015.

Material received: January 11, 2024.

Material peer-reviewed: January 16, 2024.

Edited material approved by authors: January 26, 2024.