ORIGINAL ARTICLE

SANTO, Victor Martins do Espirito [1], KOMYAMA, Fabio Hideki Fernandes [2], OJIMA, Felipe Kenzo Nonaka [3], ABREU, Renato Ferreira [4]

SANTO, Victor Martins do Espirito. Et al. Affordable low cost filling machine for small producers. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year 06, Ed. 01, Vol. 06, pp. 96-127. January 2021. ISSN: 2448-0959, Access Link: https://www.nucleodoconhecimento.com.br/engineering-mechanical-engineering/low-cost-filling, DOI: 10.32749/nucleodoconhecimento.com.br/engineering-mechanical-engineering/low-cost-filling

SUMMARY

Currently, the beverage market is a branch in which big names establish themselves, and in this rigidity imposed by big brands, small brands see great difficulty in their insertion in the market, and even in classifying themselves as a particular competitor of such giants of the market. Marketplace. However, the cachaça branch, a genuinely Brazilian drink, shows itself to be contrary to this logic, with small producers dominating the market as pointed out by Pegn magazine. business plan * (2019). Aguardente 4 Pontes is an emerging company for the production of alcoholic cocktails, throughout its history it has developed in relation to the means of production, and due to the high demand, a project was developed for the automation of its production line, which until then it was manual. For that, it was taken as an objective to build a prototype of this machine to increase the company’s productivity. First of all, the prototype was created and developed through the Arduino UNO component and its ATMEGA328 micro controller, expecting as a result the dynamization of a production line that filled the liquid precisely in the bottle. With the automation of the production line, we seek to make the process faster and more effective, being able to lower the cost of producing a product by replacing human labor in the manufacturing process, thus being able to direct employees to other functions, increasing considerably productivity. This is expected to achieve a model that satisfies the factory’s production needs, so that the company can increase the requirements for agility, efficiency and production capacity. The research is based on readings from other documents and qualitative research. As a methodology, the construction of a prototype, and theoretical basis behind the relevance and value of a low cost filling company in the market, with which it should confirm the effectiveness of the project.

Keywords: Automation, beverage filler, productivity, prototype.

1. INTRODUCTION

Automation is a system that making the use of mechanical and electrical techniques unified by computer programs has the ability to boost and optimize the production processes to which they were planned, being able to find it in various sectors of the economy. There are 3 types of automated production line: Fixed Automation, Programmed Automation and Flexible Automation (ARAUJO, 2018).

In this research will be used the fixed automation mainly used for repetitive process production lines. In order to produce a low-cost filler that enables micro producers to enter the beverage market. In view of the difficulties of the small producer who can have an increase of up to 70% on the value of his product due to the high amount of taxes on alcoholic products, leading to a great obstacle, and proving the difficulty of growth in this market, which ultimately ends up disstimulating producers thus decreasing economic activity as stated by Campos (2017).

It is of paramount importance for production companies that are looking for the international market to have automation plans for their production line, just as Aguardente 4 Pontes outlines plans and aims at a fully automated factory to achieve this feat. Because it is of paramount importance for the market search in foreign countries to have the ability to support a greater demand made by these markets larger than the country’s home country, and to adapt well the needs and tastes of these places is necessary a savings of spending to be able to serve these markets at a distance (DE PAULA et al , 2018), savings that can be passed with the automation of the production line that will decrease the number of employees performing the same task, in addition to making a smaller percentage of errors in the packaging stage and accelerate the manufacturing process by cheapening the cost of the final product.

The search of the company Aguardente 4 Pontes for the international scenario is a challenge, which is intended to be achieved through the automation of its production. In view of the above, this article has the bias demonstrated the construction of a miniature prototype of the final project of the production line that can make the role of filling the bottles, and tamp them, in order to replace the work that the employee has to perform, which ends up wasting useful time and effectiveness within the company, in which it could be used if other activities were performed in the place , thus generating a time savings within the company. With the implementation of the treadmill, there is a framework in which employees will not need to perform manual production tasks and thus have more time to perform other activities involving logistics or other sectors of the company (DOCUSIGN COLABORADOR, 2018).

2. DEVELOPMENT

2.1 HISTORY OF THE AGUARDENTE 4 PONTES

The story of Aguardente 4 Pontes begins with the idea of taking better advantage of the fruits of a jabuticaba tree, and with a magazine that his daughter brought, José Maria Martins de Siqueira created the opportunity of his own business (AGUARDENTES 4 PONTES, 2020).

Figure 1 – Catalog cover Aguardente 4 Pontes

Starting at home in 2002, his business evolved, first from his parents’ home to his own home, and from his own home to a farm with a factory, as a spatial increase was needed to supply demand. And just like in the space, the style of the products also changed, at first, liquors and drops were the main products of the company, but over time they paved the way for the beat market that is now the company’s flagship. Using milk they created an unmistakable and pioneering mixture that at first will already win the taste of customers, and so the homemade creation was for the professionalization of your business. And this is the story of aguardente 4 pontes, which today has all its products that are benchmarks in quality (SIQUEIRA, 2020).

2.2 CURRENT PERSPECTIVE

The beverage market is a medium of high competition where there are very old companies that have a lot of influence in the market. The aguardente 4 pontes has been officially on the market since 1985, but started its activities only in 2006. The company aims at quality above all, being the pioneer in several well-known flavors today, and instead of the strategy of prioritizing unbridled sales of a product without quality, it values the quality of its products above all. So, knowing that whoever buys again buys, the company follows this way, and with the faithful clientele has the mission of every month to attract more representatives in new places to expand the brand. Consumer approval is his biggest marketing, and he is currently targeting the international market with the intention of again in other countries with promising markets to disseminate his product, taking a little taste of Brazil around the world.

However, for this it has the difficulty of semi-artisanal production that limits the amount of its production (SIQUEIRA, 2020).

Figure 2 – Rear of the Catalog of Aguardentes 4 pontes

For the automation was done the research was done where models of machines were seen that fulfilled the service required by the company and prices were obtained between 60 thousand and 280 thousand reais for machines capable of performing the desired activities, but given such investment, problems began to appear. One of the problems that have appeared is the national demand that does not make the machine viable for such a price until the end of international negotiations, thus making the high cost prevent the automation project (SIQUEIRA, 2020).

2.3 PROJECT PROPOSAL

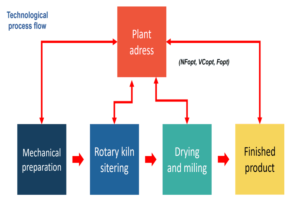

To solve this, the group’s mission was to achieve a viable solution and make a design of the operating scheme of the future automated factory, in a way that is efficient and inexpensive, being a measure for the company. However the project took much greater consequences, and enabled an entry machine model for small producers with a value far below the market, and still meet the needs of the automated factory model gives Aguardentes 4 Pontes.

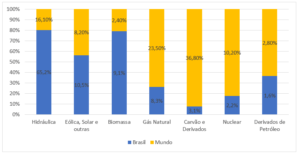

3. THE INTERNATIONAL CONSUMER MARKET

The motivation of the search for an international market is given to the reason that consumer markets in other countries are very attractive for investment, because they may become a large part of the brand’s customers in the future, as shown by the study by Vilela (2004) in which it demonstrates China and Brazil as major trading partners, given the potential of trade between the two countries in 2004. The predictions made by Vilela (2004) not only materialized but exceeded the goal of R$ 16.6 billion in one year, reaching the incredible mark of US$ 19.9 billion in the 1st half of 2020 (VALOR GLOBO, 2020), also taking into account that the first half of 2020 was an atypical semester due to the paralizations in trade and the great crisis caused by the global pandemic of COVID 19. In addition to the fact that the food and beverage sector is the second most exported by Brazil to China, in 2009 reaching the mark of 27.52% of all exports made according to data from the MDIC/SECEX analyzed in the study by Feistel (2009), and only two years later in 2011 have increased to 32.13% in a second study by Feistel (2011).

With large markets as well as China’s in sight, The Company Aguardentes 4 Pontes wants to expand its range of consumers, focusing on countries such as Canada and those of the greater Northeast Asia. In order to export the line of beats – Rainha da Mata” – aims at the dissemination of the most characteristic flavors of each country as the head post of the individual campaign within it, such as: “Beat the milk base Canelinha to Canada, and the most characteristic flavors of the places of campaign focus for the exported in an initial way” (SIQUEIRA , 2020).

Figure 3 – Product catalog Spirits 4 Bridges

Growth expectations are high according to analyst Packler (2020) of International Relations of the company, which predicts the export of minimum lots of U$100,000.00 if there is acceptance by the target market (SIQUEIRA, 2020).

And so with this capacity of great growth provided by these large markets, Abrandentes 4 Pontes aims to expand its production line to be able to provide the outside an quality product with a good price, so that within its market and marketing strategies succeed in the market.

3.1 BENEFITS OF INDUSTRIAL AUTOMATION

One of the main characteristics of industrial automation according to Sebrae (“What are the most common problems when starting a business?”) is the fact that the significant reduction of errors resulting from the electronic and mechanical integration in the production line, which allows the reduction of manual tasks by employees, thus leaving more staff to be able to be delegated other tasks. The tasks being better distributed will make the company more productive and profitable without having to invest in more labor thus configuring a better management of the business (EQUIPE RUNRUN.IT, 2018).

Wasting time within a company is a subject that should be more taken into account when discussing a company’s problems, since Blanding (2018) states in his interview with Amabile in Harvard Business School magazine that this problem alone generates a loss of about $100 billion a year in the United States alone. Therefore, with process automation, employees who were only in the manufacturing area could be easily relocated or trained to perform other functions within the company in order to improve the productive dynamics of the company.

You can’t let go of the increase in the reliability of processes that in addition to becoming safer are infinitely times more accurate and faster which makes the production of a product much faster than if it were done manually, in addition to other benefits such as increased productivity, reduced bureaucracy and agility in tax calculation , and a very high efficiency in the inspection process (SEBRAE, Know the Importance of industrial automation tools).

The benefits of automation are not only concentrated on the productive issues, but are also in the greater safety provided in the factories by it, where after a comparison made within Volkswagen factories. The comparison showed that the absence by accident or fatigue ranges from 3.5% to 4% in factories that did not yet have an efficient automated system, and in factories with adequate automation the percentage varies from 1.9% to 2.0%, because the automation done avoided the unhealthy risks of workers, and with less effort required, fatigue was avoided, and in the long run preserves the health and health of the worker (JUNIOR et al , 2003). However, quite the contrary to what is said about the supposed unemployment caused by industrial automation, in fact automation saves many jobs and companies because today if automated factories were closed they would leave many employees unemployed, because without automation it would not be possible to operate them, outside that industrial automation allowed the female insertion in areas where they were dominated by men , because with the elimination of operations considered dangerous or requiring a physical effort of man, because the same services are being performed and performed by robots, and with this sum of factors were opened the doors for women integrated into these better working conditions (JUNIOR et al, 2003).

Therefore the future of a producer is at some point automating its production, because soon industry 4.0 will be something present and common in people’s daily lives, and it is necessary that this adaptation occurs the changes that are to come (DIGITAL HOUSE, 2020). The low cost model of the filler will benefit the small producers who at present find themselves unable to grow in this path it is the initial road of the company, so having its entire production made in a machine capable of performing the 4 operations that are sold at a very high cost in the market: “bottle, feed the lids, seal the bottle , and insertion of the identification sticker.” These operations on a machine can go over 30,000 reais and reach up to more than 100,000 reais. Comparing the prices between the models, it will be easy to understand that for the one with little capital for an affordable and fair price to be able to buy a single machine that can perform all operations will benefit him tremendously, so it will boost not only his economy, but to foster that of many other producers who may be interested in entering the area given the facility available in production provided by the prototype.

3.2 TAX BURDEN THAT EMBEHES GROWTH

From the need to review the laws of the Simples Nacional, former President Michel Temer signed without any veto the sanction of the complementary bill of the National Simple that came into operation in 2018, after great pressure from Abracerva – Brazilian Association of Craft Beer. With the sanction, the turnover limit of microenterprises went from R$ 360,000 reais to R$ 900,000 reais, for small producers the limit of R$ 3.6 million per year became R$4.8 million (CELSO JR, 2016). In addition to the billing threshold for individual microentrepreneurs (“MEIs”) who also received a ceiling increase, with the new limit value of R$81,000 reais. In addition to the increase in the deadline for micro and small entrepreneurs to pay off their debts that from 60 months passed to 120 (MARIA CEVADA, 2016).

Although it was a big step for micro and small producers, according to Campos (2017, p. 10) many micro and small producers still remain excluded from the Simples Nacional and that a legislative review would be necessary.

To solve this issue, LC 123/06 was edited in order to establish facilitating rules in the various legal fields, including in the tax field, called “Simples Nacional”. This diploma, despite being an advance in tax exemption and the debureaucratization of the activity, still present substantial problems, not realizing the differentiated and favored treatment provided for constitutionally to micro and small enterprises (CAMPOS, 2017).

According to Cervieri Junior (2014) cited in Campos’ research (2017, p.71), the beer market in Brazil is in short dominated by 4 large companies, which together concentrate 98.4% of the market, with the respective companies: Ambev (67.9%), Petrópolis (11.3%), and the new group of Heineken and Brasil Kirin representing 10.8% of the market.

This oligopoly that emerged through many processes of merger and acquisition between breweries, exceeds even national barriers, and the oligopoly represents the first major barrier for entry producers, because this is a market dominated by major brands, and its structure is centralized (MARCUSSO, 2015). This barrier itself already has many limitations, because the small consumer portfolio is very limited in numbers and products compared to those of large breweries, which alone manage to have a wide range of products to please the most diverse preferences (CAMPOS, 2017). And there is another great differential between large breweries and small micro companies, which comes to be the biggest decisive character in the market that differentiates them, this differential is the name of the brand that was built on large investments in advertising, which in 2013 reached the mark of R $ 5.864 billion in ads in the beverage industry (CERVIERI JUNIOR et al. , 2014). Thus characterizing another market exclusion suffered by small producers.

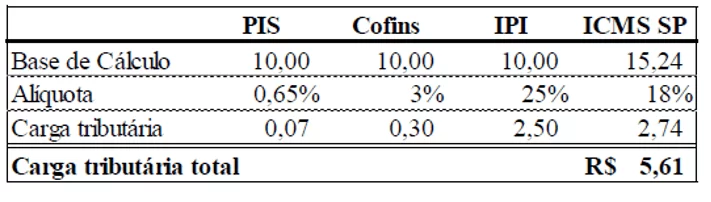

The producer’s expenses for the manufacture of the product often come to be a major obstacle by the monopoly of raw materials (SEBRAE, 2016), which adds to the labor cost for production and distribution to be passed on in the final value of the product. but as if it was no longer a great challenge to be in a market competing with these large companies, the tax burden seems to go against the face of the producer. Considering a value of R$ 10.00 a liter of cachaça Campos (2017, p.95) states.

In the case of IPI, TIPI provides, as a rate, 25%.

For the product, the PIS has a rate of 0.65%, according to Art. 2,§4,I, B, Law 10,637/02, and COFINS, in turn, has a rate of 3%, pursuant to Art. 2,§5,I, b, Law No. 10,833/03.

In the case of ICMS, the internal rate of the State of São Paulo for cachaça is 18%, resulting in R$ 2.74.

Therefore, for sale to the final consumer, cachaça, whose value to the producer has been R$ 10.00, leaves the establishment costing R$ 15.60.

Table 1 – Tax burden present in cachaça

Taking into account this high tax burden, the small producer finds himself in an unfavorable situation before the great monopoly, because even selling less ends up paying the same tax burden that large breweries pay, being at a disadvantage for paying much more than can thus configure a real confiscation. This takes into account that small producers make the direct sale to the final producer, because if there is any intermediary by reseller or retailer the tax burden can easily lead to a 70% increase on the product (CAMPOS, 2017).

In addition, the cost of distribution can reach up to 10% and 13% of the consumer price, other than the budget for achieving this distribution value can correspond to three times the value of the investment of the company’s installation (ROSA et al, 2006). This becomes another major disadvantage for the small micro producer that has no structure or network to pay for the distribution of the product.

Still, micro and small companies account for a large share of Brazilian GDP[5], according to Campos (2017, p.28) “[…] the smallest companies are responsible for generating approximately 27% of Brazilian GDP, thus participating in more than a quarter of the national gross domestic product.” And not only do they represent a large part of GDP, but in 2013 they generated 41.4% and 52.1% of the jobs with a signed portfolio (SEBRAE, 2015), and, therefore, they are of paramount importance to the country’s economy, so in addition to revisions in sanctions and laws, a model that cheaped their production would be very effective in remaining in the market. Industrial automation could provide micro and small producers with great growth opportunities, and a low-cost model would be excellent for their sales to begin to gain consistency and overcome these barriers.

4. DESIGN OF THE PROTOTYPE

4.1 COMPETITORS ON THE MARKET

The prototype was designed to meet the general needs of the production of a beverage factory, complying with the fill, the positioning of the lid, the covering, and the identification by adhesive. These in short are the primary activities for The Spirits 4 Bridges at the time of making their beats, starting from these bases activities, was designed a machine capable of performing all at the lowest possible value, and that is able to have a considerable and profitable production for its user.

Research was done about the competitors of the market, in which it was found that in most cases with a machine capable of holding 1000ml the values of the machines of each process would easily exceed R $ 10 thousand reais per unit and a machine that performs a single activity exceed the house of R $ 38 thousand reais, adding the values of all the machines necessary for the primordial of the production of beverages more eventual costs and expenses as the freight and assembly, the project would undoubtedly pass the house of R $ 50 thousand reais choosing the cheapest models. The high value becomes a hindrance and ends up not enabling for the small producer who often does not have even half the value of the project in revenue, still having to pay all the necessary expenses of the factory itself (SIQUEIRA, 2020).

Table 2 – Comparison of prices and features. Made: 05/11/2020

| Machine models | Type of operation | Production capacity | Price |

| Scepter Liquid Filler with two nozzles 1000-5000ml | Filler (semi-automatic) | Up to 3000 bottles/hour | R$17.590,00 |

| Threader / tapper | Cover and cover distribution (automatic) | Up to 2,500 bottles per hour | R$36.000,00 |

| SPCA model labeler (flat bottle) + Hot-stamping modulated date | Labeling (semi-automatic) + dating (automatic) | Average of 2,000 bottles/hour | R$34,800,00 + R$7.400,00 |

| Low-cost filly design | Full 2 nozzle automatic filler | Average 220-600L/h | From R$5,000.00 to R$10,000.00 |

| Features | Machine Type | H/H production | Total value |

| Total low cost | Automatic | 220L-660L/h | R$5.000 – R$10.000 |

| Total high cost | Automatic | 2,000 bottles | R$78.217,59 |

Source: Author

Apart from these obstacles, with these separate machines the manufacture of beverages would still need many employees and manpower to operate the machines in each process because they are all semi-automatic machines, outside that the rate of packaging may not be satisfactory enough to cover all these expenses, which ends up not enabling this type of automation for small producers.

Following the analysis of Payback investments[6], such an investment in the long term could be attractive depending on the amount of cash available from the company, however its analysis is summarized in the time of recovery of investment made, and which has as parameters periods in which in short are in months, in which the enterprise is redeemed by the profits obtained (PAMPLONA; MONTEVECHI, 2006).

However, according to Pamplona and Montevechi (2006), Payback has its limitations for not observing the financial situation after the analysis period and disregarding the value of money in time. Taking into account only “the minimum rate of attractiveness”, which demonstrates that on paper an investment of this size could be interesting, but in reality there are other factors to consider, such as the fact that a small producer has its production and manufacture of products in a volatile way and without fixed clientele, also there are no large numbers of orders made in fixed ways to be able to make a long-term account with stability. In addition to adding the issue of the various workers who would still operate the production because it is semi-automatic. Therefore the same method can only be used as a support tool for investment analysis in this case.

This should all be taken into account when making an investment, since in 2018 about 762,900 companies closed their doors for various reasons (IBGE, 2018), most of which are closed by corporate mismanagement that lead several organizations to bankruptcy several times before even completing their 5th year of existence. In many cases corporations victims of poor business planning and disorganization during the processes are victims of the administration itself, which as an aggravating factor are pressured by the high tax burden of the Brazilian government and often by debts resulting from high-value investments that have been thwarted (NUNO, 2019). Therefore everything should be taken into account, and not just the thought of this project being an investment and having the chance to generate a future return. To accomplish this, it is necessary a well-structured planning and a roadmap of the steps, so that the company can make a high investment of this without ending up going bankrupt, as well as many companies that end up closing their doors before they even generate the first results (DINO, 2019).

4.2 ADVANTAGES IN RELATION TO COMPETING PRODUCTS

Small companies often do not have the financial or corporate structure to bear the weight of a large investment as necessary for the purchase of said machines previously mentioned, adding to the fact of the high mortality analyzed by Sebrae-SP (2010) in which about 46% of small companies closed their doors in São Paulo after the 3rd year. For this and other reasons obstacles for the entry of small producers of beverage on the market, the model of low cost filler becomes a very efficient and viable solution for these producers who find great difficulty in the hostile environment that is the creation of a small micro company. The prototype will have a malleable assembly and tailored to the specifications desired by the customer, so the amount of filling per hour can be changed at the time of the order to meet the needs of the producer, so the project is subject to technical changes, such as: The pressurizer chosen, hose size, quantity of nozzles, the diameter of the liquid outlet nozzle for the bottle , and even the size of the project itself.

The low-cost filling model performs all the operations necessary for complete filling, from filling the bottle to engraving the identification by the adhesive. When compared to their competitors in the market, the difference in value is clear, and for an affordable price, micro and small producers manage to have a filling machine capable of carrying out the 4 operations, and on top of that, with a proportional filling rate and capable of sustaining a micro and small company that will have great savings with employees and labor. All of this without making large loans and high-cost investments that often end up compromising the company’s financial health and bankrupting it, as the business magazine Pegn demonstrates. da Globo ** (“Say goodbye to financial problems) about measures to be taken before investments are made.

> Use a maximum of two-thirds of the resources in infrastructure and personnel and save the rest for a marketing plan and working capital formation.

> Calculate the return period: If the projected monthly profitability is less than 2% compared to the initial investment, it is best to review the project.

The Aguardentes 4 Pontes como micro small empresa, has its entire manual production, and the filling is made by a pressurizer, with an average of 300L/h, for it a simple model of two nozzles would supply about 73.33% of the production alone, thus relocation the employees to other sectors of the factory. The investment would become viable if the aim was to replace labor for economy and growth, but Abrandentes 4 Pontes aims for the international market. Therefore, the prototype should already have more robust properties in order to have a high rate of filler, reaching or surpassing the mark of 3,000L/h of filler per hour, and it is with these specifications that the project will be changed in the future to adapt to the factory (SIQUEIRA, 2020), through greater investment than was proposed in this study, given the desired specifications.

Therefore, with this ability to modify the desired quantity and specifications of fill, the project can offer an excellent proposal to micros and small producers seeking a refuge and a solution to improve their chances of success in the market. The adversities present in the competitive market and taxation will remain until greater power measures are taken, however with a low-cost filler the small producer will be able to significantly reduce labor costs, and save time and staff who will be able to perform other tasks in the company. In addition to encouraging new micro and small producers, who can start just buying the filler and thus risk the market producing their drinks, until it consolidates its brewery and thus contributes to the Brazilian economy by fostering new jobs of signed portfolio.

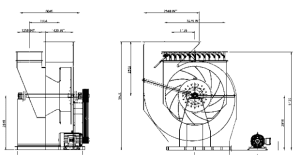

5. STRUCTURAL CONSTRUCTION

5.1 STRUCTURAL PART

The prototype began to be made from a drawing in AutoCad where it was calculated the size of the base of the bottle, the size of the circle and the base to support the project.

After this began the construction of the prototype, first worked with the woods, with the aid of a saw and a manual walrus was cut 2 plates of compacted wood of 1 cm thick and 1 MDF plate of 10mm thickness in the measurements of 520x520mm, and was ordered a circle of MDF with 260mm diameter and 30mm thickness , because the circle had to be perfect not to affect the design.

As soon as the support base of the project was built, a cage was designed with rectangular shaped iron bars with 15x15mm on the side, in order to support the pneumatic cylinder to be able to stay static in the air, as well as to place the simple liquid reservoir and support it to place the distributor of caps, and among others. First marked the iron, 4 bars in the measurement of 24cm, 4 bars in the measure of 52cm and 4 bars in the measure of 75cm. Then, with the help of a professional with the necessary tools, the bars with their dimensions were cut in the disconnector. Then, were all the bars welded with the aid of a welding machine, and with other irons subsequently cut to measure for the bottle of 1 liter of The Spirits 4 Bridges, a support was made for the hose that makes the bottle fill. Soon after, a 70mm x 70mm x 3mm bespoke iron plate was made to serve as the horizontal steering regulator of the pneumatic trigger. Soon after, 4 holes were made in the wood with a tico-tico saw to serve as a fitting between the base and the iron cage, and in order to join these two parts were made 4 holes in the lower bars and in the 3 wooden plates with a drill, and then screwed everything so that it connected the base of the project with the iron cage. Meanwhile, the bases were made to place the bottles, 12 compacted wooden plates were cut in the dimensions of 20mm x 10mm x 10mm, and were glued and nailed to the wooden circle, so that they can serve as bottle position fasteners.

The wooden base, so as to allow its rotation and still distribute the weight of the objects placed on it, was reinforced with the use of 4 silicone wheels, which are flexible and able to change their direction when necessary. Thus, they were fixed just below the mold where it will house the object, establishing an angle of 90° at each point.

Figure 4 – Left image: Swivel base (bottom view); Right image: Swivel base (top view).

Once the base and the prototype cage were completed, a hole was drilled in the bottom of the base with a 20 mm diameter drill taking 20 mm in depth, and a through hole was drilled in the circle with the same drill. Then, 2 more holes of 5 mm in diameter were made in the platform, through, for coupling the motor to the table. Then the components were joined, the stepper motor was fixed on the table and the motor shaft was coupled to the rotating base. This procedure was done by means of an axle clamp, which was developed by the group. The adjustment was established when the four wheels reached uniformity when touching the platform.

After adjusting the engine and base, the pneumatic cylinder was placed screwing it into the previously made square iron plate so that it can be attached to the iron bar in the desired position, and malleable to change. To make the tank was purchased a gallon of water of 5 liters, inserted a hose with 2 silicone rubbers so that there is no leakage of liquid, and serving as support for the tank was cut and put a compacted wooden plate of 20cmx20cmx1cm, which was attached to the top of the cage. The liquid valve has been positioned on an “L” shaped iron rod in which the tip houses the valve and its central measurement houses the ultrasonic sensor.

After making the main structure, a distributor of caps was elaborated with the materials that had been purchased, and so with them was designed a wooden structure with 3 wooden boards with the respective dimensions of 6cm x 40cm x 1cm, which were glued so that there is a space of 20mm high inside, which is the space occupied by the cover model of The Spirits 4 Bridges. In this way, to make the part of the nozzle where the bottle cap comes out, a decorative bottle was cut by removing the top and bottom of the bottle, leaving only the middle part that was divided into 2 parts that were stapled on the side of the wood to form a nozzle so that when the mouth of the bottle passes below the distributor of caps , take a cap, and result, another fall with the action of the weight of gravity and pressure by the weight of the other caps, get this new cap stuck in the nozzle. When testing for the first time did not work, after observing that the cap was going up, a wooden plate of 6cm x 10cm x 1cm was glued on top of the structure, which solved the problem, making functional and effective the distributor of caps.

Once the structural part of the project was completed, the prototype was painted with black spray paint and liquid white paint. After that the structure to place the cap was fastened with Hellerman ribbons and with ropes in the iron structure. The base of the tank was secured with Hellerman tape on the top of the iron structure, and the cylinder that was removed for the painting was again attached to the structure.

Finally, a box was reused to house the electronic components, along with the power supply. The material of the box is made of cardboard and it was used solely for the purpose of protecting the components in relation to dirt or dust.

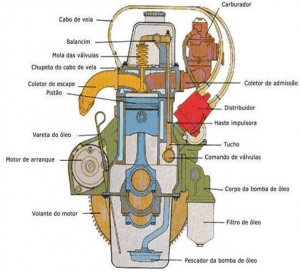

5.2 ELECTRIC PART

5.2.1 ARDUINO UNO

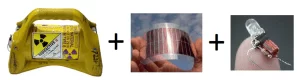

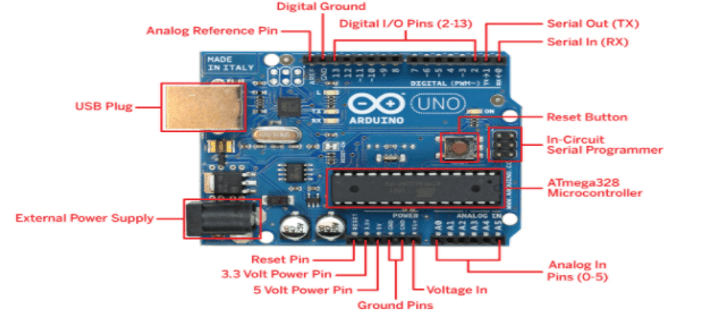

Figure 5 – structural example of Arduino Uno

The Arduino Uno is the first invented card that has USB, it is also the most used board, having the Microcontroller ATmega328, with 14 digital pins that can be configured as input or output and 6 of these pins can also be used as PWM output, has 6 analog input pins, a 16Mhz oscillator crystal, programming connector, reset button to restart the board, connector for power source, and USB connection (SOLDA FRIA, 2019).

The choice of Arduino Uno is due to the fact that it is a component with low prototyping cost, it is programmed by C++ language, that is, it is easy programming, and has access to a greater number of free simulation software, in addition, it has a vast number of tutorials and projects on the internet, and also has an excellent efficiency in prototypes “We conclude that it is possible to observe the accuracy of the sensor and the efficiency of Arduino as controller” (FRANCIO et al, 2017).

The CLP’s , in turn, despite having greater security and precision in the controls of the process, often have a bad contact, require numerous kings and periodic maintenance, as well as have a very high cost (FREITAS, 2013).

Table 3 – Comparison of values between an Arduino and a CLP

| MARKET PRICE COMPARISON TABLE (2020) | |

| COMPONENT NAME | CURRENT MARKET PRICE (2020) |

| Arduino UNO R3 ATMEGA328 | R$32,90 |

| PROGRAMMABLE LOGIC CONTROLLER WEG CLP CLIC02 24VCC 20VR | R$1.297,58 |

Source: Author

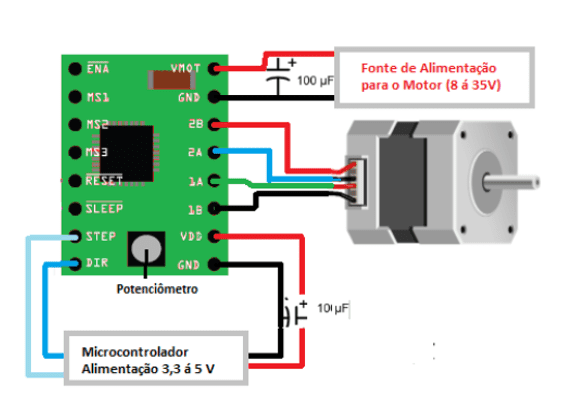

5.2.2 DRIVER A4988

Figure 6 – Structural Example Driver A4988

The A4988 driver is a driver designed to operate with bipolar stepper motors, it has 5 step modes, the Full, Half Step, Four Steps, Eight Steps and Sixteen Steps. The driver has 2 voltages one that it sends to the engine which is 8-35V and ±2A and one to its microcontroller which is 3.3-5V.

As for pinout the driver has the MS1, MS2 and MS3 pins which are the step mode controls, STEP and DIR that are the control of steps and direction, VDD and GND which is the power of the microcontroller(3,3-5V), 2B, 2A, 1A and 1B which are the motor coil connections, VMOT and GND that are the power of the motor(8-35V) and the ENABLE pins RESET and SLEEP (KOYANAGI, 2017).

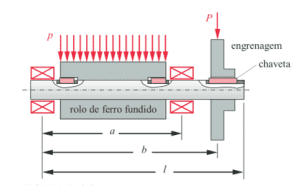

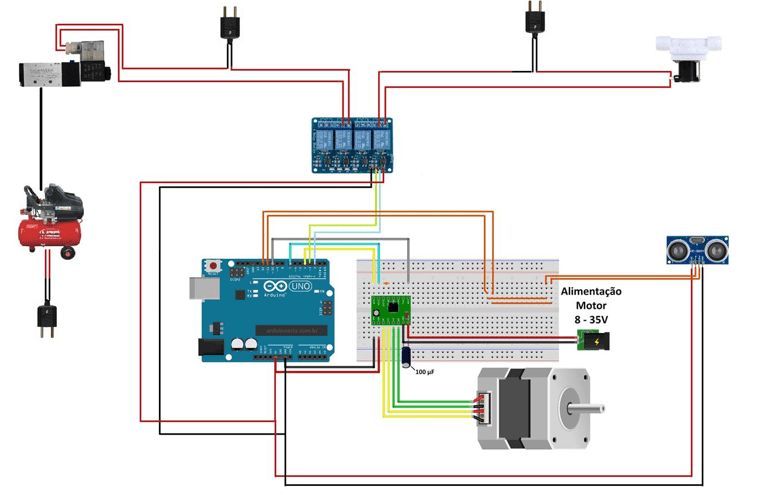

5.3 ASSEMBLY

Figure 7 – Electrical diagram of the low-cost filler prototype

The electrical part of the prototype requires 3 sockets, one for the compressor, one for the solenoid valve and one for the electric water valve.

The Arduino UNO is connected to the notebook by the USB input, and through it is executed the programming commands, the Arduino is connected to the driver by pins 4 that is connected to the DIR port that controls the direction, 7 which is connected to the STEP port that controls the steps in the engine, by pin 10 that is connected to enable, and by the VCC and GND pins of the Arduino for power.

The A4988 driver in addition to the connections with the Arduino is connected to the motor power supply by the VMOT and GND pins in parallel with a capacitor of 100μF, is with reset and sleep connected, and is connected to the NEMA23 bivolt motor by the 2B, 2A, 1A and 1B pins which are the motor coil connections, the MS1, MS2 and MS3 pins have not been used therefore, it was not necessary to change the step control.

In addition, the Arduino is connected to the l-side by pins 2 and 3 which control the signals respectively to open and close the key and is connected to the ultrasonic sensor by pins 11 that is connected to the TRIGGER that sends the high frequency waves and the 12 pin that is connected to echo that captures the waves thus receiving the information , both the relheaand the sensor are connected to the Arduino VCC and GND.

The lens controls the passage of the current of the electric and pneumatic valves and the pneumatic valve is connected to the compressor that provides the pressure necessary to perform the procedure of capping the bottle.

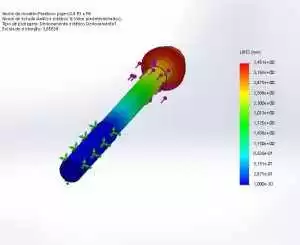

5.4 OPERATING FLOWCHART

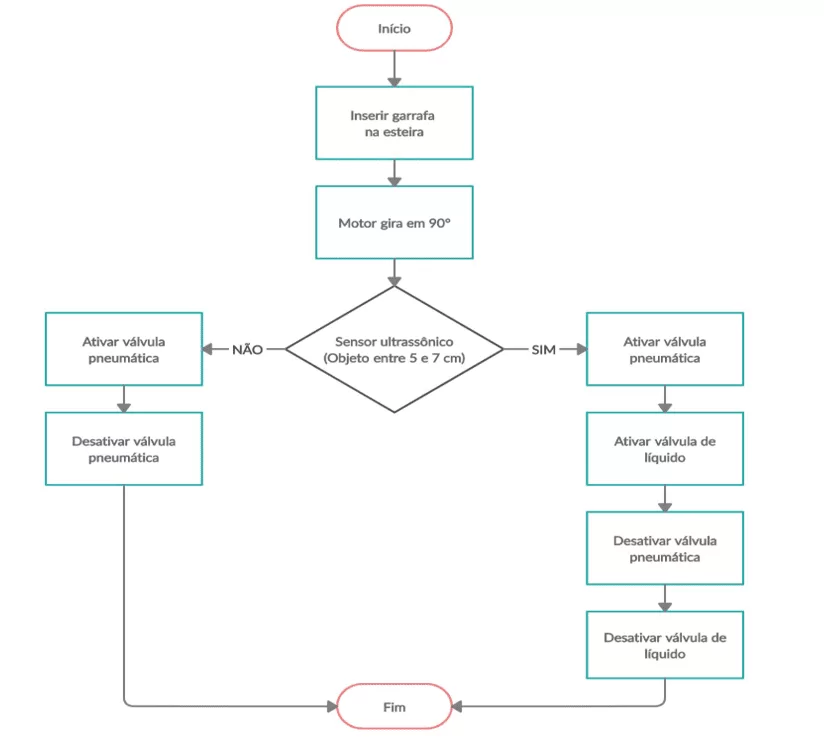

Figure 8 – Prototype stepper motor flowchart

5.4.1 OPERATING LOGIC

When inserting the bottle into the conveyor, the motor that rotates 90 degrees is activated, that is, if each step is 1.8 degrees because it is working with full step, the motor needs 50 steps, which is represented in the program as follows:

“for(x = 0; x < 50; x++)”.

The ultrasonic sensor sends wave-shaped signals to find out if the bottle is positioned between 5 and 7 cm, it serves as a safety for the liquid valve to activate only when the bottle mouth is positioned under neath the electric water valve.

If the ultrasonic sensor does not detect the bottle, the pneumatic valve that controls the piston is driven for 5 seconds, time required to cap the bottle. However, if the sensor detects the presence of the bottle in addition to triggering the pneumatic valve, it also activates the liquid valve for 60 seconds, time required to fill the bottle.

5.5 FINAL CONSUMER MARKET AND AREAS OF OPERATION

Brazil as the country of origin of cachaça and being the only one capable of actually being able to manufacture the traditional and original cachaça, has great market possibilities, according to Silva (2018) and Pinheiro (2018), it is expected that around 2,500 breweries will emerge by 2035, and that even in the most realistic and less optimistic numbers projected by Beck (2014), in 20 years would reach about 1,500 breweries with an annual production around 700 million liters , which would represent 2.5% of the market. With this data can be noted Brazil as a great country still for market growth and that would have a target audience for a low-cost filler, able to help these 1,500 breweries to rise and establish themselves in the market.

The target audience is certainly the micro and small producers, who seek an entry machine to establish themselves and gain experience in the market, who manage to have a median production sufficient to trade within their region and state, until they reach stability and move to new markets and new consumers.

According to Ferreira et al. (2011), cited by Silva (2018) small producers have a great advantage in specific relation to large companies, which gives, the wide variety of styles.

the micro brewers have a different proposal for the market, compared to the large companies in the sector. They are producers specialized in exotic and natural beers, using craft manufacturing techniques, to deliver a wide variety of styles, in order to satisfy the most demanding customers and consumers of more “gastromized” products, penetrating a market not yet occupied by large breweries

Therefore, it is of paramount importance and relevance for this range of producers to have the greatest amount of options to promote their products and contribute to the development of the economy and its brands.

FINAL CONSIDERATIONS

The study of the low-cost filler generated several references and information about the market, so it completed the model as fit, through investment, for insertion in the market, having as target audience micro and small beverage producing companies. Also, complementing the collection of this research niche so little treated between industrial automation and the beverage industry academically.

Together with the projected low-cost model, the economic situation of the Aguardantes 4 Pontes factory was analyzed, and it was found that, with approval for international marketing, it would be able to make the investment, and have the prototype adapted in a way that meets the needs of the company.

Still the first prototype of maximum initial cost of R $ 880.00, performed well through the chosen parts and applied configurations, where he was able to perform all operations, except to identify the bottle through the adhesive. Not through the failure in the manufacture of the same, but in cost, because to make the piece that would act in the identification would eventually exceed the limit in the budget established for this model, which has as characteristic simplicity and price.

The group’s perspective on the project is an optimistic perspective, in view of the good data obtained with market research and the area of operation, in addition to the preparation of the initial prototype that for the materials used had an excellent performance of 100 liters per hour using only one nozzle and without any pressurizer to give pressure to the liquid at the time of filling, thus fulfilling 1/3 of the production that is currently exercised in the Spirits 4 Bridges, also taking into account that the project budget did not cost a minimum wage. The group also considers the idea profitable to presentations at investment conferences, so that the project can be started, thus helping thousands of small producers to automate their productions. In addition to creating other model lines with higher fill value to reach other audiences as well.

And it is recommended for further studies, the feasibility of making a large-scale production model integrated with fair and affordable price for medium producers, and that research is also done on the area of automation and market analysis and small business taxation, because there was great difficulty in finding studies that there were both in sets. And it will be a major contribution to automation being present in research that proves that it can help many types of businesses and trades have a better chance of success in the future.

REFERENCES

ARAUJO, Edgar Oliveira. “Um estudo de automação visando o Aumento de produtividade na construção civil”. UFRJ. Pag. 11-15. 2018.

BATISTA, Josiane. “Entenda o que é Payback e saiba como calcular”. Flua, 2019. Disponível em:< https://www.flua.com.br/blog/entenda-o-que-e-payback-e-saiba-como-calcular/>. Acesso em 25/11/2020.

BECK, M. “O potencial da cerveja artesanal brasileira: uma análise econométrica”. O Globo. Disponível em:<http://blogs.oglobo.com/dois-dedos-de-colarinho/post/o-potencial-da-cerveja-artesanal-brasileira-uma-analise-econometrica-550457.html.>. Acesso em: 07/11/2020

BLANDING, Michael. “American Idle: Workers Spend Too Much Time Waiting for Something to Do”. Harvard business school, 2018. Disponível em:< https://hbswk.hbs.edu/item/american-idle-employees-are-wasting-way-too-much-time>. Acesso em: 06/11/2020

CAMPOS, Carolina Silva. “As micro e pequenas produtoras de bebidas alcoólicas artesanais excluídas do Simples Nacional e os custos tributários: uma necessidade de revisão legislativa”. Universidade de São Paulo Faculdade de Direito de Ribeirão Preto. 2017.

CELSO JR, Luís, “Sancionada a lei que inclui micro e pequenas cervejarias no Simples Nacional”. Bar do Celso, 2016. Disponível em:< https://bardocelso.com/sancionada-a-lei-que-inclui-micro-e-pequenas-cervejarias-no-simples-nacional/>. Acesso em:06/11/2020.

CERVIERI JUNIOR, Osmar; VEIRA, Calos Takashi Jardim da. “O setor de bebidas no Brasil”. BNDES setorial 40, 2014, p. 93-130. Disponível em:< https://web.bndes.gov.br/bib/jspui/bitstream/1408/3462/1/BS%2040%20O%20setor%20de%20bebidas%20no%20Brasil_P.pdf> Acesso em: 06/11/2020.

DE PAULA, Roberta Manfron; FERREIRA, Manuel Portugal; RESENDE, Paula da Silva Quinte. “Aplicação das teorias de internacionalização em pequenas empresas”. FUMEC, 2018, p. 1-4

DIGITAL HOUSE. “Indústria 4.0 no Brasil: como a era industrial transformou as profissões e o mercado brasileiro”. Digital House, 2020. Disponível em:< https://www.digitalhouse.com/br/blog/industria-4-0-no-brasil >. Acesso em: 05/11/2020

DINO.” Em 2019, empresas continuam fechando por má gestão empresarial”. Terra, 2019. Disponível em:<https://www.terra.com.br/noticias/dino/em-2019-empresas-continuam-fechando-por-ma-gestao-empresarial,ed4b5b87d79d2c574911ec214c467cb6t0fw7sqd.html>. Acesso em:05/11/2020.

DOCUSIGN, COLABORADOR. “Entenda o que é automação empresarial”. Docusign, 2018. Disponível em: <https://www.docusign.com.br/blog/entenda-o-que-e-automacao-empresarial>. Acesso em: 10/10/2020.

RUNRUN.IT, “Como a ociosidade influência as relações entre tempo e trabalho”. Runrun.it, 2018. Disponível em:< https://blog.runrun.it/tempo-e-trabalho/>. Acesso em: 06/11/2020

FEISTEL. Paulo Ricardo*; HIDALGO, Álvaro Barrantes**. “A competitividade das regiões brasileiras no intercâmbio comercial com a China”. UFSM*, PIMES**, 2011. Pag. 3-9.

FEISTEL, Paulo Ricardo*; Hidalgo, Álvaro Barrantes**. “O intercâmbio comercial nodeste-china: desempenho e perpectivas”. UFMS*, UFPE**, 2011. Pag. 3-4.

FERREIRA, R. H.; VASCONCELOS, M. C. R. L.; JUDICE, V. M. M.; NEVES, J. T. de R. “Inovação na fabricação de cervejas especiais na região de Belo Horizonte. Perspectiva em ciência da informação”, Revista Produção Online. Florianópolis, SC, p.171-191, 2011.

FRANCIO, Alexandra Campganaro; Zaccaria, Jhoni Alan; Tessari, Everton; Villa Paula. “Sistema de controle de gotejamento utilizando Arduino” IFRS, 2017. Disponível em:<https://eventos.ifrs.edu.br/index.php/MEPE/MEPE2017/paper/view/3753>. Acesso em: 09/11/2020.

FREITAS, Carlos Márcio. “CLP – Controlador Lógico Programável – Parte 1”. Embarcados, 2013. Disponível em:< https://www.embarcados.com.br/clp-parte1/>. Acesso em: 09/11/2020.

JÚNIOR, Antônio Pereira de Araújo; CHAGAS, Christiano Vasconcelos das. “Uma rápida análise sobre automação industrial” DCA-CT-UFRN Natal – RN, 2003. Pag. 2-3.

KAYONAGI, Fernando. “Motor de passo com Arduino e o Driver A4988”. FernandoK, 2017. Disponível em:< https://www.fernandok.com/2017/12/motor-de-passo-com-arduino-e-o-driver.html>. Acesso em: 08/11/2020.

NUNO, ADELMO.” Falta de planejamento financeiro: 74% das startups fecham após 5 anos de existência”. Startupi, 2019. Disponível em:< https://startupi.com.br/2019/08/falta-de-planejamento-financeiro-74-das-startups-fecham-apos-cinco-anos-de-existencia/>. Acesso em: 06/11/2020

MARCUSSO, Eduardo Fernandes. “As microcervejarias no Brasil atual: “sustentabilidade e territorialidade””. 2015, 171p. Dissertação (Mestrado em Sustentabilidade na Gestão Ambiental) – Universidade Federal de São Carlos, São Carlos.

MARIA CEVADA. “Microcervejarias incluídas no Simples Nacional!”. Maria Cevada, 2016. Disponível em:< https://www.mariacevada.com.br/2016/10/microcervejarias-incluidas-no-simples.html>. Acesso em: 06/11/2020.

PAMPLONA E. O.; MONTEVECHI, J. A. B. “Engenharia Econômica I. Análise de investimentos” UNIFEI, Itajubá, 2000.

Revista Pegn. de negócios Globo**. “Dê adeus aos problemas financeiros”, revista Pegn. de negócios Globo. Disponível em :<http://revistapegn.globo.com/Revista/Common/0,,ERT176137-17198,00.html>. Acesso em: 06/11/2020.

Revista Pegn. de negócios Globo*. “Pequenos produtores dominam o mercado da cachaça diz pesquisa”. Globo, 2019. Disponível em:<https://revistapegn.globo.com/Negocios/noticia/2019/05/pequenos-produtores-dominam-mercado-da-cachaca-diz-pesquisa.html>. Acesso em 10/10/2020

ROSA, Sergio Eduardo Silveira da; COSENZA, José Paulo; LEÃO, Luciana Teixeira de Souza. “Panorama do setor de bebidas no Brasil”. BNDES, 2006. Disponível em:< https://web.bndes.gov.br/bib/jspui/bitstream/1408/2607/1/BS%2023%20Panorama%20do%20Setor%20de%20Bebidas%20no%20Brasil_P.pdf>. Acesso em: 05/11/2020

SEBRAE. “Quais os problemas mais comuns ao iniciar um negócio?”. Sebrae. Disponível em:< https://www.sebrae.com.br/sites/PortalSebrae/artigos/quais-os-problemas-mais-comuns-ao-iniciar-um-negocio,9ac2312905e27510VgnVCM1000004c00210aRCRD>. Acesso em: 03/11/2020.

SEBRAE-SP. “Doze anos de monitoramento da sobrevivência e mortalidade de empresas”. SEBRAE-SP, 2010. Disponível em: <https://m.sebrae.com.br/sites/PortalSebrae/ufs/sp/sebraeaz/mortalidade-e-sobrevivencia-das-empresas,d299794363447510VgnVCM1000004c00210aRCRD>. Data de acesso: 06/11/2020.

SEBRAE. ANÁLISE DO CAGF. “Evolução do saldo Líquido de criação de emprego formal no Brasil pelos pequenos negócios”. Sebrae, 2014. Disponível em:< https://m.sebrae.com.br/Sebrae/Portal%20Sebrae/Anexos/Caged%20-%2002%202014.pdf>. Acesso em 05/11/2020.

SEBRAE. “Conheça a importância das ferramentas de automação comercial”. Sebrae. Disponível em:< https://www.sebrae.com.br/sites/PortalSebrae/ufs/ap/artigos/conheca-a-importancia-das-ferramentas-de-automacao-comercial,c058105e03380610VgnVCM1000004c00210aRCRD>. Acesso em: 02/11/2020.

SEBRAE. “Estudo de Mercado para Cachaça da Bahia”. Sebrae, 2016. Disponível em:< https://www.sebrae.com.br/Sebrae/Portal%20Sebrae/UFs/BA/Anexos/Estudo%20de%20Mercado%20-%20Cacha%C3%A7a%20da%20Bahia%20-%20vers%C3%A3o%20para%20publica%C3%A7%C3%A3o.pdf >. Acesso em: 07/11/2020.

*SILVA, Ruan Ferreira Carmo da; **PINHEIRO, Eduardo Medonça. “Plano financeiro de uma microcervejaria artesanal, maranhão”. 2018 – *Universidade Estadual do Maranhão (UEMA), São Luís, MA **Faculdade Pitágoras, São Luíz, MA

SIQUEIRA, Hélder Relizer Martins de, sócio proprietário Aguardentes 4 Pontes. Entrevista pesquisa de mercado da envasadora de baixo custo. [Entrevista cedida a] Victor Martins do Espirito Santo. Mogi Das Cruzes – SP – 2020.

SIQUEIRA, José Maria Martins de, Proprietário Aguardentes 4 Pontes. Entrevista pesquisa de mercado da envasadora de baixo custo. [Entrevista cedida a] Victor Martins do Espirito Santo. Mogi Das Cruzes – SP – 2020.

SOLDA FRIA. “O que é um Arduino, para que serve, como funciona, onde comprar?”. 2019, Fonte:< https://www.soldafria.com.br/blog/o-que-e-um-arduino-para-que-serve-como-funciona-onde-comprar >, Acesso em: 07/11/2020.

TAUHATA, Sérgio; CID, Thiago. “Dê adeus aos problemas financeiros”. Revistas de negócios pegn. da Globo. Disponível em: <http://revistapegn.globo.com/Revista/Common/0,,ERT176137-17198,00.html>. Acesso em: 07/11/2020.

Valor Globo. “Comércio entre Brasil e China pode bater recorde neste ano”. Globo, 2018. Disponível em:<https://valor.globo.com/brasil/noticia/2020/09/08/comercio-entre-brasil-e-china-pode-bater-recorde-neste-ano.ghtml>. Acesso em: 12/10/2020.

VILELA, EDUARDO V. M. .”As relações comerciais entre Brasil e China e as possibilidades de crescimento e diversificação das exportações de produtos brasileiros ao mercado consumidos chinês.”. PUCSP, Pag. 29-37. 2004

ANNEX – ITEMS REFERENCES ANALYSED IN THE MARKET

Silicone wheels.

Available in:<https: produto.mercadolivre.com.br/mlb-1387583947-4x-rodinha-silicone-gel-35mm-moveis-2-ctrava-2-strava-4-pc-_jm?matt_tool=”26177295&matt_word=&matt_source=google&matt_campaign_id=6542512723&matt_ad_group_id=77682048439&matt_match_type=&matt_network=u&matt_device=c&matt_creative=385099545261&matt_keyword=&matt_ad_position=&matt_ad_type=&matt_merchant_id=146234528&matt_product_id=MLB1387583947&matt_product_partition_id=306248980482&matt_target_id=pla-306248980482&gclid=Cj0KCQjwufn8BRCwARIsAKzP697Qg6fSzJJuPDhZFr6RWaqa5lnlwu6UY70hhlyfkGj2LvyNIGTXOWcaArAcEALw_wcB”>.</https:> Mercado Livre, 2020. Accessed: 01/11/2020.

-Air filter regulator and pneumatic lubricator ¾.

Available in:<https: produto.mercadolivre.com.br/mlb-1010170454-filtro-de-ar-regulador-e-lubrificador-conjunto-lubrifil-34-_jm?matt_tool=”79246729&matt_word=&matt_source=google&matt_campaign_id=6542746973&matt_ad_group_id=82254694281&matt_match_type=&matt_network=u&matt_device=c&matt_creative=385099301982&matt_keyword=&matt_ad_position=&matt_ad_type=&matt_merchant_id=120617127&matt_product_id=MLB1010170454&matt_product_partition_id=472057081367&matt_target_id=pla-472057081367&gclid=CjwKCAiA4o79BRBvEiwAjteoYL6p1u0YYd8oQ4KavHtog2EiIRFK3BokxLklFFUaRZXgrpYzmdXRSBoCgIAQAvD_BwE”>.</https:> Mercado Livre, 2020. Accessed: 01/11/2020.

-Pneumatic trigger simple action and solenoid.

Available in:<https: produto.mercadolivre.com.br/mlb-1548460883-kit-atuador-pneumatico-cilindro-pneumatico-simples-acao-_jm?matt_tool=”79246729&matt_word=&matt_source=google&matt_campaign_id=6542746973&matt_ad_group_id=82254694281&matt_match_type=&matt_network=u&matt_device=c&matt_creative=385099301982&matt_keyword=&matt_ad_position=&matt_ad_type=&matt_merchant_id=120617127&matt_product_id=MLB1548460883&matt_product_partition_id=472057081367&matt_target_id=pla-472057081367&gclid=Cj0KCQjwufn8BRCwARIsAKzP695u5DVpne7uEmDI_MjR1GIFrVqYKYRyWpeoJkyTKJcpS8cXYcaFYtAaAnsfEALw_wcB”>.</https:> Mercado Livre, 2020. Accessed: 01/11/2020.

-Air compressor for pneumatics – R$ 989,90

Available in:<https: www.lojadomecanico.com.br/produto/122493/21/159/motocompressor-de-ar-88-pes3min-25hp-50-litros-110220v/153/?utm_source=”googleshopping&utm_campaign=xmlshopping&utm_medium=cpc&utm_content=122493&gclid=Cj0KCQjwufn8BRCwARIsAKzP694qYCy2jyQpkXFiJbfTqu_KuXEdyMp7lh3KYu-K8G_Eh5pU90koXt8aAvYOEALw_wcB”>.</https:> Loja do Mecânico, 2020. Accessed: 01/11/2020.

REFFERENT VALUES TO TABLE 2

Available in:<https: www.cetroloja.com.br/envasadora-de-liquidos-1000-5000ml-com-dois-bicos=””>.</https:> Cetro, 2020. Accessed: 05/11/2020.

Available in:<http: tudela.com.br/datador-modulado/=””>.</http:> Tudela Rotuladoras, 2020. Accessed: 05/11/2020.

Available in:<http: tudela.com.br/portfolio-item/rotuladora-modelo-spca-frasco-plano/#=””>.</http:> Tudela Rotuladoras, 2020. Accessed: 05/11/2020.

Available in:<https: produto.mercadolivre.com.br/mlb-1301214128-rosqueadeira-tampadeira-automatica-_jm#position=”13&type=item&tracking_id=fb49b4ab-fbcd-4c03-b49c-54a8e7fa5c78″>.</https:> Mercado Livre, 2020. Accessed: 06/11/2020.

APPENDIX – FOOTNOTE REFERENCES

5. Gross domestic product – GDP is the sum of all final goods and services produced by a country, state or city, usually in one year (IBGE, 2019).

6. Payback – (or “return” in Portuguese) is the calculation that represents the time it will take for your investment “if you pay” (BATISTA, 2019)

[1] Graduated in Technical Mechatronics Integrated To High School.

[2] Graduated in Technical Mechatronics Integrated To High School.

[3] Graduated in Technical Mechatronics Integrated To High School.

[4] Advisor. Graduated in electrical engineering from the University of Mogi das Cruzes.

Submitted: December, 2020.

Approved: January, 2021.