ORIGINAL ARTICLE

ROCHA, Francisco dos Santos [1], SILVA, José Rodrigo Sevalho da [2]

ROCHA, Francisco dos Santos. SILVA, José Rodrigo Sevalho da. Contribution to the Concrete Structure Project Executed with Rolled Pebbles in the City of Manaus – Usual Procedures and Recommended Standards. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year: 08, Issue: 07, Volume: 01, pp. 103-128. July 2023. ISSN: 2448-0959, Access Link: https://www.nucleodoconhecimento.com.br/civil-engineering/concrete-structure, DOI: 10.32749/nucleodoconhecimento.com.br/civil-engineering/concrete-structure

ABSTRACT

Initially, the aggregates used in concrete construction available in the building materials market in the city of Manaus were assessed. Samples were collected from the North, South, East, and West zones to determine their quality indices and physical properties, with the aim of producing concrete mix designs using regional materials. Subsequently, prototypes of slabs and beams were constructed to obtain concrete cores for evaluating their compressive strengths. These elements were exposed to outdoor environmental conditions, including rain, sunlight, and wind. One group was also subjected to wetting and drying cycles at the beginning and end of each day. Additionally, cylindrical specimens were cast for axial compression tests. During the concrete curing phase, these specimens were identified and divided into two groups exposed to different conditions: immersion in a saturated calcium hydroxide solution, outdoor exposure, outdoor exposure in a covered environment, and outdoor exposure subjected to wetting and drying cycles. The experiments were conducted over the course of a year to assess the influence of environmental conditions, including relative humidity and temperature, on concrete strength. The results revealed that environmental conditions, during the period from July to November, in conjunction with the standard curing method adopted in the city of Manaus (wetting the surfaces at the beginning and end of each day), affect the concrete’s strength gain, resulting in a final value lower than expected. This not only reduces the load-bearing capacity of the structure but also increases concrete porosity and reduces its modulus of elasticity. Therefore, when designing and constructing concrete structures in Manaus, the region’s specific characteristics must be considered. These considerations should encompass aggregate types, environmental conditions, and the local curing practices.

Keywords: Environmental conditions, Concrete with rounded gravel, Concrete curing.

1. INTRODUCTION

The prevailing standard governing the design of concrete structures, NBR 6118 (ABNT, 2014), lists basalt, diabase, granite, gneiss, limestone, and sandstone as aggregates for concrete composition. In most states, artificial coarse aggregate, crushed stone, is offered, with the advantage of granulometry being in accordance with the type of construction. Consequently, the experiments that supported the standard were conducted with artificial aggregates, making formulas involving the strength of concrete executed with other types of aggregates invalid.

In the city of Manaus, rounded pebbles are predominant, natural coarse aggregate obtained from the riverbeds of the State of Amazonas, due to environmental damage caused by the extraction of rocks from the soil. The use of rounded pebbles in the concrete mix for construction works in the city of Manaus is common, partly due to its lower cost of acquisition.

Field professionals must produce concrete with equal or superior strength to that specified in the project. The requirements for this to occur depend on various factors, as recommended by Andrade and Helene (2010). The main factors include the quality of the concrete’s component materials, the appropriate procedure during the concrete execution phase, the curing process, and the temperature and humidity of the air at the construction site.

During the phase of obtaining concrete strength on the job site, in addition to the quality of its component materials, conditions must be established for chemical reactions to occur fully during the concrete’s hardening process. According to NBR 14931 (ABNT, 2023), until satisfactory hardening is achieved, the concrete must be cured and protected against harmful agents to: prevent water loss from the exposed surface, ensure adequate surface strength, and ensure the formation of a durable surface layer.

In some parts of the country, peculiar regional procedures are still adopted, with empirical knowledge transmission prevailing. In Manaus, concrete curing is commonly carried out by wetting the structure at the beginning and end of the day, or outdoors without the use of any artificial process. The influence of the region’s environmental conditions on concrete strength during its hardening phase is also not taken into consideration. In concrete structure design, environmental factors should be considered, as noted by Lima (2011), along with the influence of different urban climates on concrete quality (VALIN JUNIOR, 2016).

This study evaluates the interference of environmental conditions on the gain in concrete strength during the hardening phase in Manaus, considering the typical curing procedures in the region and those recommended by NBR 5738 (ABNT, 2016).

2. LITERATURE REVIEW

According to NBR 6118 (ABNT, 2014), concrete structures must meet the minimum requirements for quality, load-carrying capacity, service performance, and durability during construction and service. Additional requirements should be established in collaboration between the structural designer and the client. The minimum quality requirements include safety against rupture (load-carrying capacity), the structure’s ability to remain in full working conditions throughout its service life (service performance), and the structure’s capability to withstand environmental influences expected at the construction site (durability).

Concrete strength is one of the main parameters that influence these three representative groups of quality requirements for a concrete structure, affecting safety against rupture, among other factors. Therefore, during the execution phase of structural elements, the quality of the concrete’s constituent materials, the procedures used during the molding of elements, and concrete curing should be observed. The primary aim is to delay water evaporation, which is employed in the mix preparation, in order to meet the structural performance requirements specified in NBR 15575-1 (2021).

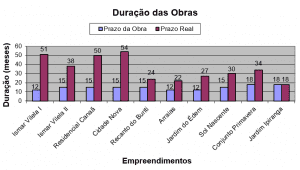

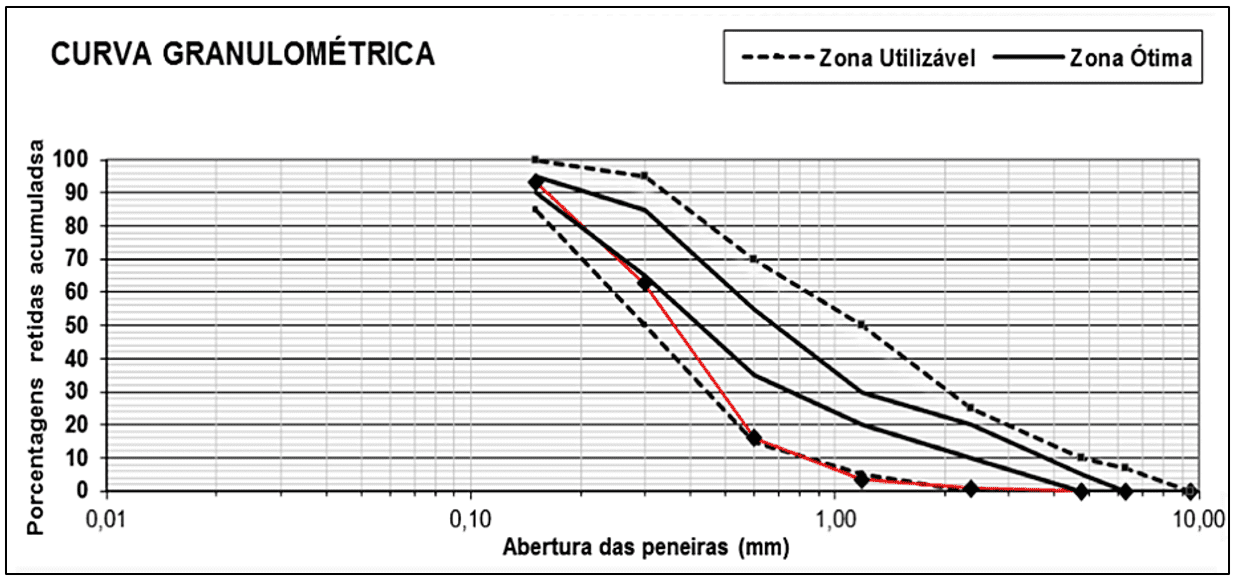

NBR 7211 (ABNT, 2022) prescribes limits for the particle size distribution, defining working particle size distribution ranges as shown in Figure 1 for fine aggregate: the usable zone (defined by dotted lines) and the optimal zone (defined by solid lines). The particle size distribution curve, represented by red line segments, illustrates, for example, the low quality index of sand collected in the Japiim district in the South zone of the city of Manaus.

Figure 1: Particle size distribution of sand collected in the Japiim district

Regarding the quality of sands offered by construction material stores in the city of Manaus, Table 1 shows more comprehensive results obtained by Brito; Rocha; Fernandes (2015), characterizing sands collected in the southern zone of Manaus. These data indicate poor sand quality, especially concerning the fineness modulus. The sand available to consumers in the southern zone is fine, with a fineness modulus less than 2.2, following NBR 7211 (ABNT, 2022).

Table 1: Results of particle size distribution tests; clay content in lumps and friable materials; fine material passing through the 75μm sieve by washing; and organic impurities

| Neighborhoods | ||||||||||||

| Santa Luzia | Betânia | São Francisco | ||||||||||

| # | P1 | P2 |

MF = 1,83 DM = 1,18mm TAM = 0,5% MFI = 0,1% IO = light color |

# | P1 | P2 |

MF = 1,58 DM = 1,18mm TAM = 0,4% MFI = 0,3% IO = light color |

# | P1 | P2 |

MF = 2,12 DM = 1,18mm TAM = 2,0% MFI = 0,2% IO=dark color |

|

| 4,75 | 0 | 0 | 4,75 | 0 | 0 | 4,75 | 0 | 0 | ||||

| 2,36 | 0 | 0 | 2,36 | 0 | 0 | 2,36 | 0 | 0 | ||||

| 1,18 | 3 | 3 | 1,18 | 2 | 2 | 1,18 | 3 | 3 | ||||

| 0,60 | 15 | 18 | 0,60 | 12 | 14 | 0,60 | 26 | 29 | ||||

| 0,30 | 50 | 68 | 0,30 | 44 | 58 | 0,30 | 54 | 83 | ||||

| 0,15 | 26 | 94 | 0,15 | 26 | 84 | 0,15 | 14 | 97 | ||||

| background | 6 | 100 | background | 16 | 100 | background | 3 | 100 | ||||

| Notations: # – mesh opening (mm); P1 – retained percentage; P2 – cumulative retained percentage; MF – fineness modulus; DM – maximum dimension; TAM – content of clay in lumps and friable materials; MFI – fine material passing through the 75μm sieve, by washing; IO – organic impurities. | ||||||||||||

Source: Brito; Rocha; Fernandes (2015).

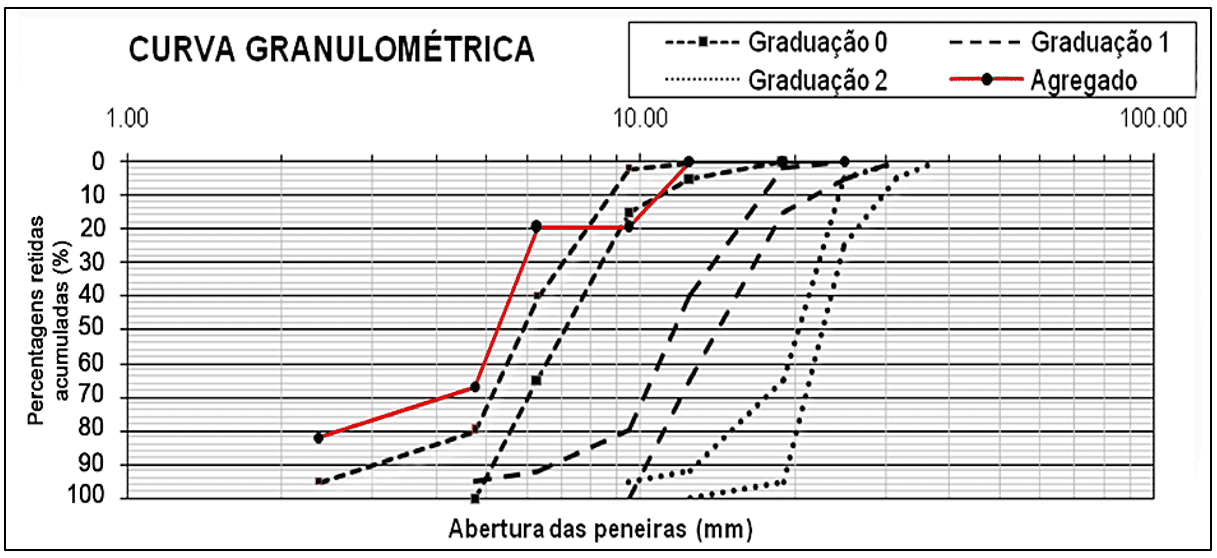

According to NBR 7211 (ABNT, 2022), the limits of the granulometric composition of the coarse aggregate are defined by the relationship d/D (smaller (d) and larger (D) dimensions of the coarse aggregate): d(mm)/D(mm) = 4.75/12.5; 9.5/25; and 19/31.5, respectively, referred to as gradations 0, 1, and 2. The granulometric curve formed by red line segments, obtained from a sample collected in the Novo Israel neighborhood, North zone, shows a low quality index of the rounded pebble regarding its granulometric distribution.

Figure 2 – Granulometry of the rounded pebble collected in the Novo Israel neighborhood

The results of tests listed in Table 2, obtained by Aoki; Rocha; Fernandes (2015), on samples collected in the North zone of the city of Manaus, indicate that the material does not have a graded granulometry. The material offered in the North zone of Manaus has high retention rates of grains in the 9.5mm, 4.75mm, and 2.36mm sieves, indicating a strong presence of fine aggregate granulometry.

Table 2: Results of granulometry tests; clay content in lumps and friable materials; fine material passing through the 75μm sieve by washing

| Neighborhoods | |||||||||||

| Cidade Nova | Santa Etelvina | Cidade de Deus | |||||||||

| # | P1 | P2 |

MF = 5,72 DM = 25mm TAM = 0,2% MFI = 0,9% |

# | P1 | P2 |

MF = 5,52 DM =19mm TAM = 0,0% MFI = 0,4% |

# | P1 | P2 |

MF = 5,13 DM = 19mm TAM = 0,2% MFI = 0,3% |

| 25 | 4 | 4 | 25 | 0 | 0 | 25 | 1 | 1 | |||

| 19 | 2 | 6 | 19 | 0 | 0 | 19 | 2 | 3 | |||

| 9,5 | 30 | 36 | 9,5 | 20 | 20 | 9,5 | 11 | 14 | |||

| 4,75 | 36 | 72 | 4,75 | 48 | 68 | 4,75 | 30 | 44 | |||

| 2,36 | 11 | 83 | 2,36 | 16 | 84 | 2,36 | 29 | 73 | |||

| 1,18 | 6 | 89 | 1,18 | 6 | 90 | 1,18 | 15 | 88 | |||

| 0,60 | 2 | 91 | 0,60 | 3 | 93 | 0,60 | 6 | 94 | |||

| 0,30 | 5 | 96 | 0,30 | 5 | 98 | 0,30 | 4 | 98 | |||

| 0,15 | 3 | 99 | 0,15 | 1 | 99 | 0,15 | 1 | 99 | |||

| background | 1 | 100 | background | 1 | 100 | background | 1 | 100 | |||

| Notations: # – mesh opening (mm); P1 – percentage retained; P2 – cumulative percentage retained; MF – fineness modulus; DM – maximum dimension; TAM – lump and friable material clay content; MFI – fine material passing through the 75μm sieve by washing. | |||||||||||

Source: Aoki; Rocha; Fernandes (2015).

These results indicate the need for the characterization of aggregates used in the concrete mix, primarily due to the location of the deposits and the aggregate collection process.

Some procedures without theoretical or experimental evidence, depending on the region, are still being used today. In the case of concrete elements, the idea prevailed that the water contained in fresh concrete does not need to be maintained in the mixture during the hardening phase of the mass. Additionally, it is common to expose concrete pieces to an uncovered environment, under the sun, to accelerate their hardening. The water-to-cement ratio in this process also receives little attention. In most of the construction works carried out in the city of Manaus, curing concrete is typically performed by wetting the surfaces at the beginning and end of the day and is generally interrupted well before the maximum cement hydration occurs, i.e., at twenty-eight days of age.

According to Neville and Brooks (2013), concrete should be kept saturated or as close as possible to it until the spaces originally filled with water in the fresh cement paste have been filled with the required amount of cement hydration products. The set of actions to keep concrete saturated is referred to as concrete curing.

In the design of concrete elements, whether structural or simple concrete elements, the construction site must be specified to choose the appropriate curing method, considering mainly the relative humidity of the environment, as recommended, for example, by Metha and Monteiro (2008). In practice, concrete curing can be omitted only in locations with high humidity and stable temperatures.

In the northern region of the country, the relative humidity of the environment can be higher than 80% for much of the year, leading to the belief in natural curing, adopted by many builders, especially by construction supervisors. This belief is unfounded because data provided by the National Institute of Meteorology show strong variations in humidity and temperature in the city of Manaus throughout the year.

Environmental aggressiveness is already addressed in NBR 6118 (ABNT, 2014) in the design of common structures and is classified as weak, moderate, strong, and very strong, to define concrete quality and reinforcement protection. For concrete structure design, this classification is related to the following types of environments: rural, submerged, urban, marine, industrial, and tidal spray regions. However, variations in humidity and temperature in each region of the country are not related to improving the durability of structures.

Several studies on the influence of natural aggregates in mortar and concrete in Manaus construction projects have been conducted due to the lack of technical specifications for these mixtures. Examples include Brito; Rocha; Fernandes (2015); Aoki; Rocha; Fernandes (2015); Rocha; Fernandes; Monteiro (2015); Rocha; Coelho; Silva (2020).

3 MATERIAL AND METHODS

3.1 STUDY AREA

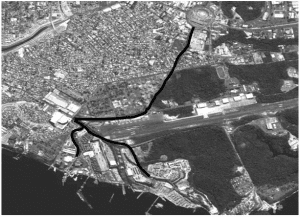

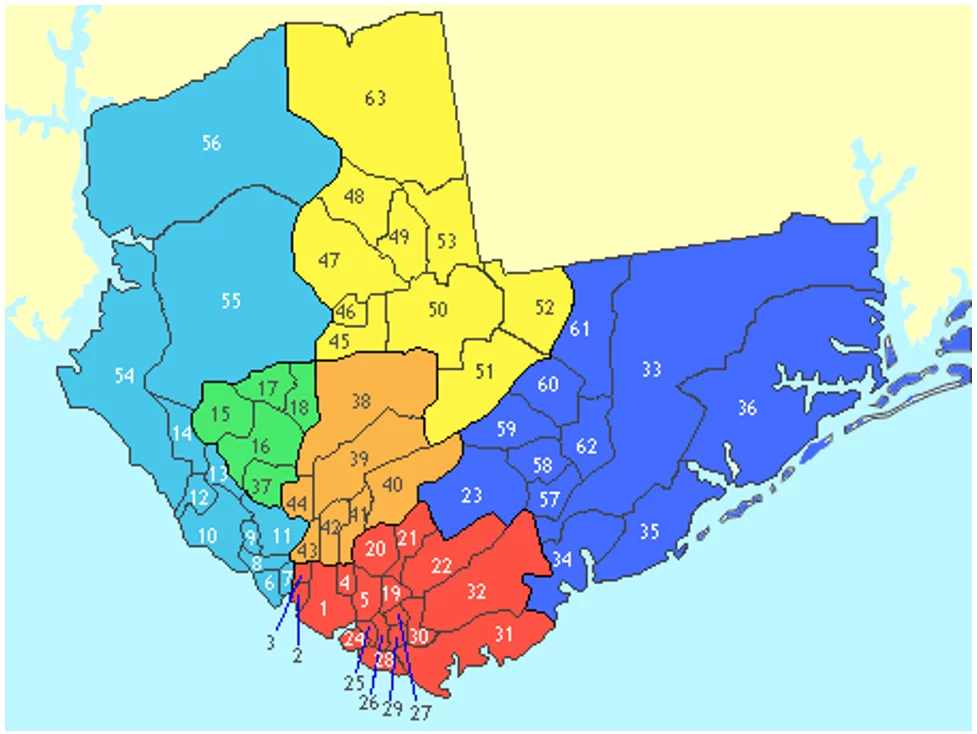

The aggregate collection area was defined based on the diversity of material quality available in the construction market, as shown in the results presented by Rocha et al. (2017), to ensure that the concrete used in the study represents the reality of construction projects in the urban region of the city of Manaus. Figure 3 shows the aggregate collection zones: North (yellow), South (red), East (dark blue), and West (light blue) for characterization tests.

Figure 3 – Map of the city of Manaus divided into zones

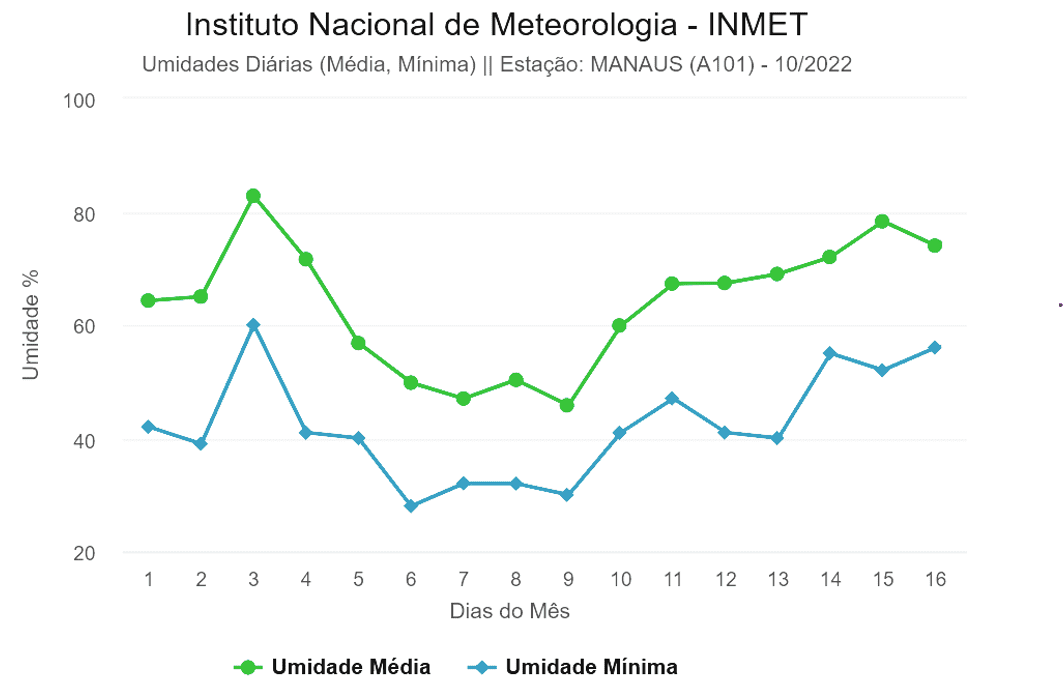

In the city of Manaus, according to the National Institute of Meteorology (INMET), the air humidity remains around 80% for most of the year. However, from July to early November, environmental humidity rates decrease significantly, sometimes dropping below 30% on certain days. This is illustrated in the graph shown in Figure 4 for the first few days of October 2022.

Figure 4: Variation of relative air humidity in the early days of October 2022

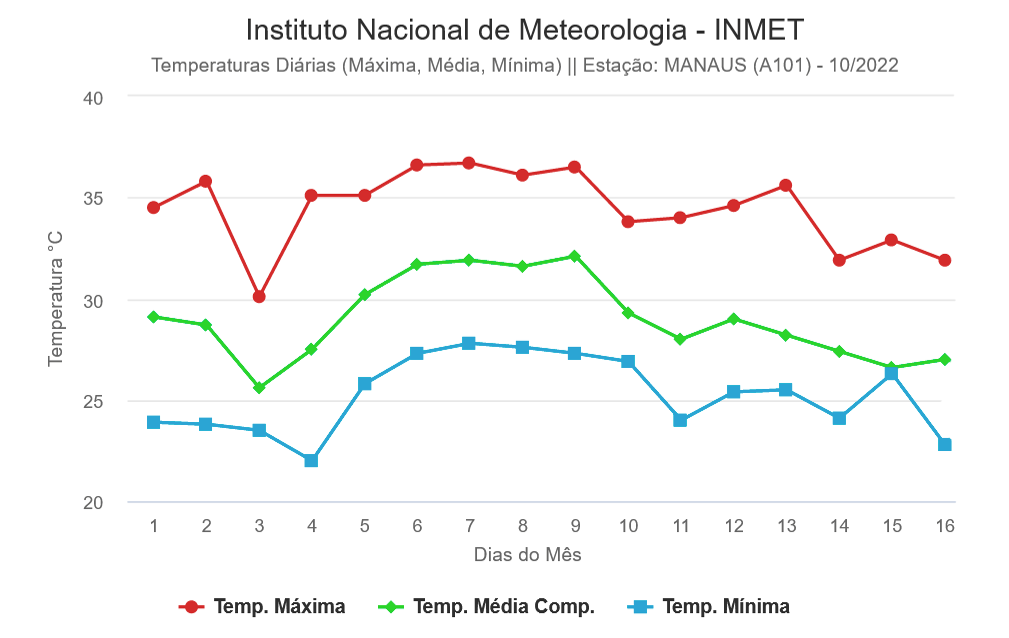

During this period, the maximum temperatures are close to 40°C, as shown, for example, in the graph in Figure 5 for the first few days of October 2022. Combined with the low daily humidity rates and high temperatures, from July to November, there are water drawdowns in the Negro and Solimões rivers and also a lack of rainfall in the region.

Figure 5: Temperature variation in the first few days of October 2022

The experiments were conducted at the facilities of the School of Technology at UEA, in the Chapada neighborhood, and at a building located in the Japiim neighborhood, where the concrete elements were cast. In these locations, during the concrete curing phase, measurements of relative air humidity and temperature were taken.

3.2 DATA

The aggregates available in the construction market of the city of Manaus are extracted from different deposits located in the riverbeds of the State of Amazonas, diversifying the characteristics of the raw material. For this reason, sand and rolled pebble samples were collected from construction material stores located in neighborhoods in the North, South, East, and West zones of the city of Manaus. All characterization tests were performed on the collected aggregates, necessary to define the concrete mix designs, following the procedures recommended by NBR 16915 (ABNT, 2021), NBR 16916 (ABNT, 2021), NBR 16917 (ABNT, 2021), NBR 16972 (ABNT, 2021), NBR 16973 (ABNT, 2021), NBR 17054 (ABNT, 2022), NBR 7218 (ABNT, 2010), and NBR NM 49 (ABNT, 2001), as well as the test to obtain the specific mass of cement, NBR 16605 (ABNT, 2017).

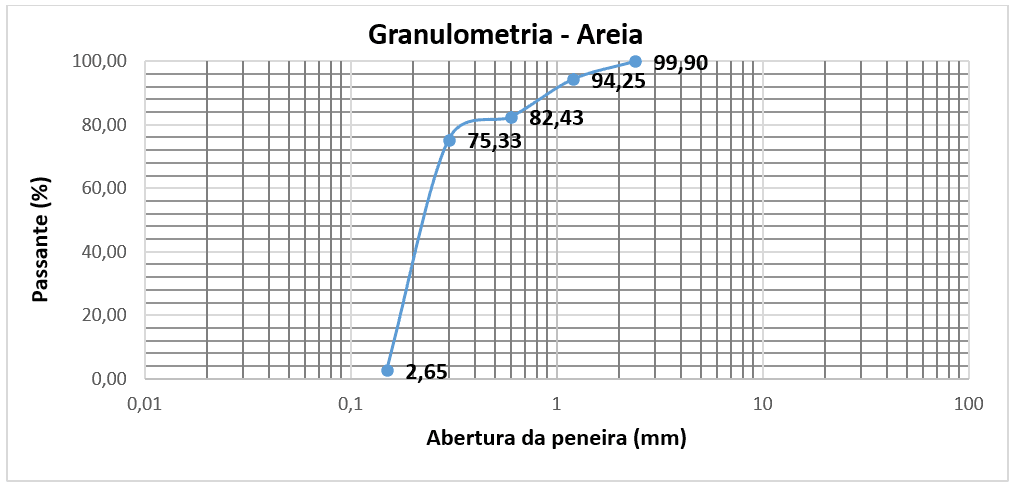

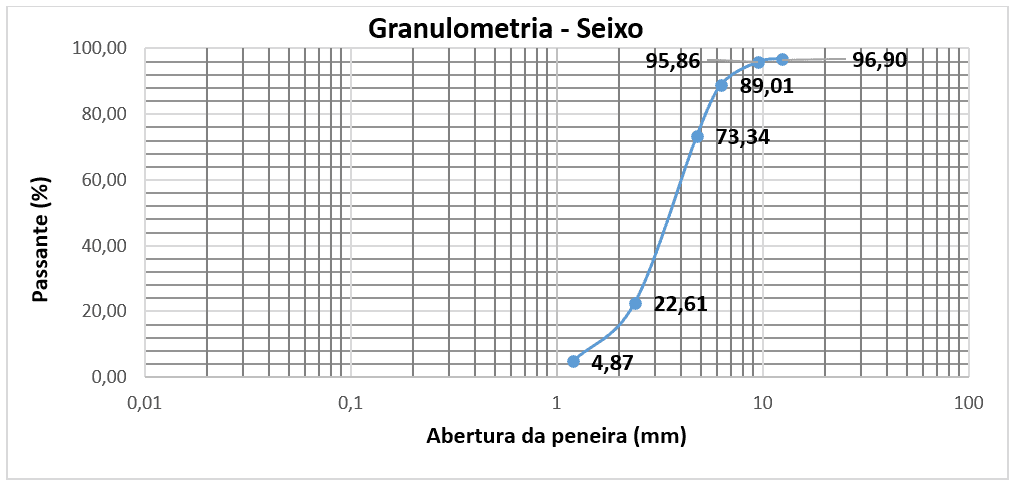

In the North zone, for example, the sand and rolled pebble presented the particle size distribution curves shown in Figures 6 and 7, and the following results for:

- a) sand: unit and specific mass in g/cm3, respectively, 1.70 and 2.60; fineness modulus = 1.45; classification = very fine sand;

- b) rolled gravel: loose and compacted unit masses, and specific mass in g/cm3, respectively, 1.64, 1.67, and 2.63; maximum diameter = 9.5mm.

Figure 6: Particle Size Distribution of Sand Collected in the Northern Zone

Figure 7: Grain size distribution of the collected gravel in the North zone

Based on this data, concrete mixes were defined for characteristic compressive strengths of 20MPa and 25MPa, considering a water-to-cement ratio of approximately 0.50 and following the procedures outlined in Terzian and Helene (1993) and Tutikian and Helene (2011). The cement, sand, and gravel ratios, in that order, were 1:1.2:2.61 and 1:1.0:2.32, respectively, for 20MPa and 25MPa.

The reference mixes with natural aggregates from the South zone, for 20MPa and 25MPa, were as follows: 1:1.2:3.35 and 1:1.0:2.97, respectively. In the East zone, the following proportions were obtained: 1:2.25:3.9 and 1:1.9:3.49. With natural aggregates from the West zone, the reference mixes were: 1:1.2:3.1 and 1:1.0:2.7.

3.3 METHODS

The aggregates used in the concrete mixes were purchased from construction material stores located in different neighborhoods of Manaus. The samples of aggregates collected in neighborhoods from the North, South, East, and West zones of Manaus were subjected to the following tests, in accordance with the applicable standards:

- a) about the quality indices of aggregates: fine material passing through the 75μm sieve by washing; clay content in clumps and friable materials; organic impurities in fine aggregate;

- b) on the physical properties of aggregates: granulometry; loose bulk density; real specific gravity.

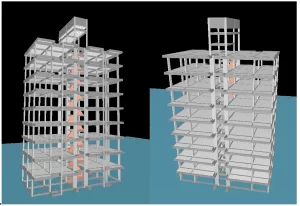

During the concrete execution phase, the procedures adopted in Manaus construction works were considered: manual execution with a hoe and mechanical execution with a 120-liter capacity concrete mixer. In each experiment, the specimens were prepared with concrete from the same batch and exposed to situations that represented both common practices and those recommended by standards.

Initially, four flat elements representing slabs and two linear elements representing beams were cast with concrete mixed in a 120-liter concrete mixer in the laboratory. These models were exposed to outdoor conditions, including sunlight, rain, and wind, for a period of seven months. During this period, half of the specimens were subjected to the usual curing process in Manaus, which involves cycles of wetting at the beginning and end of the day.

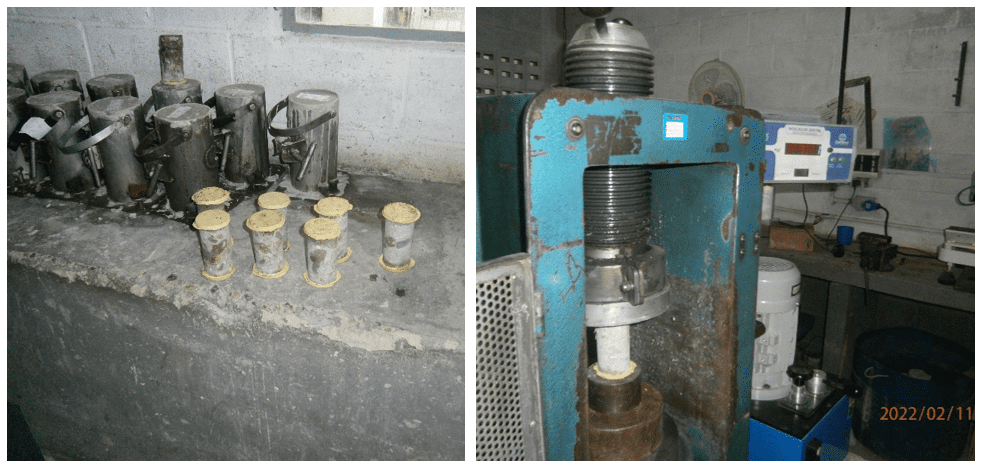

The procedure for extracting the test specimens followed the recommendations of NBR 7680-1 (ABNT, 2015) and was carried out by a specialized company in civil construction material testing. Figure 8a shows the equipment used for extracting the specimens, the DK 12 TIROLIT, and the test specimens extracted from the slab elements, as shown in Figure 8b.

Figure 8: Extraction of test specimens: a) Extraction equipment (left figure); b) Test specimens extracted from slabs (right figure)

The cylindrical specimens were capped with sulfur, as shown in Figure 9a, to ensure uniform stresses across the cross-sections. The tests were conducted using a hydraulic electric press, Pavitest brand, model I-3001-B/No. 984, as depicted in Figure 9b.

Figure 9: Testing procedures: a) Specimens capped with sulfur (left figure); b) Testing equipment (right figure)

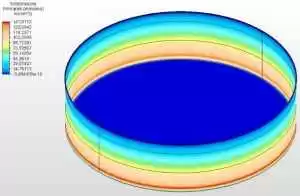

After this phase of the research, cylindrical specimens were molded using metal molds of 10cm x 20cm and 15cm x 30cm, and axial compression tests were conducted as recommended by NBR 5738 (ABNT, 2016), which deals with concrete – procedure for molding and curing specimens. With the aim of verifying the quality and uniformity of the concrete used in the work, after removing the forms, the cylindrical specimens were subjected to curing processes. The strength gains of concretes with rolled gravel in their composition were evaluated in the following situations: immersion of the specimens in a saturated solution of calcium hydroxide, as prescribed by NBR 5738 (ABNT, 2016), as shown in Figure 10a; cycles of wetting the surfaces of the concrete elements at the beginning and end of the day, as is the usual procedure in the city of Manaus; and natural curing of the concrete in the open air. In all these situations, measurements of relative humidity and temperature were taken with a digital thermo-hygrometer model MT-241A, as shown, for example, in Figure 10b.

Figure 10: Curing Procedures and Humidity and Temperature Measurement: a) Specimens immersed in the solution (left figure); b) Specimens exposed to the open air (right figure)

The experiments were carried out over the course of one year, taking into account various concrete curing methods during the hardening phase, along with humidity and temperature variations. Finally, the main concrete parameters affected by concrete curing associated with the replacement of crushed stone by natural aggregate, rolled gravel, in the concrete mix were discussed. The results obtained during this period provided technical insights for validating the research conclusions.

4. RESULTS AND DISCUSSION

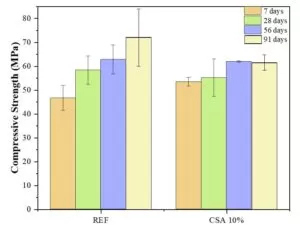

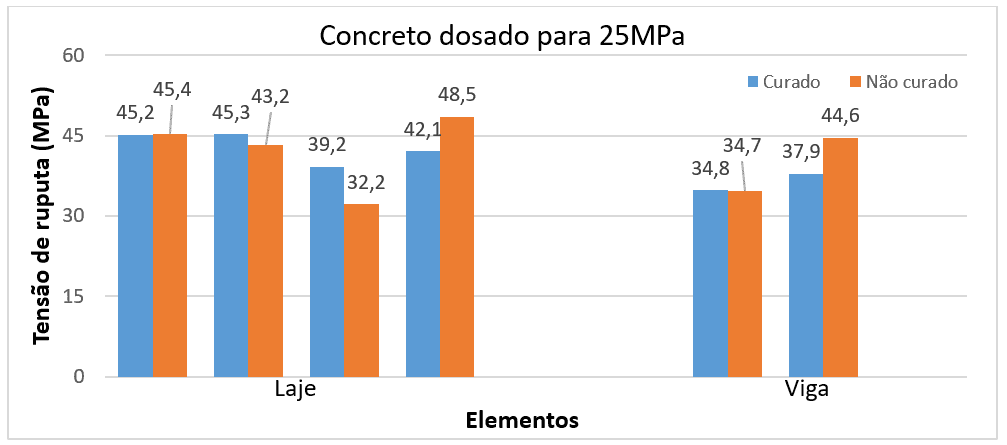

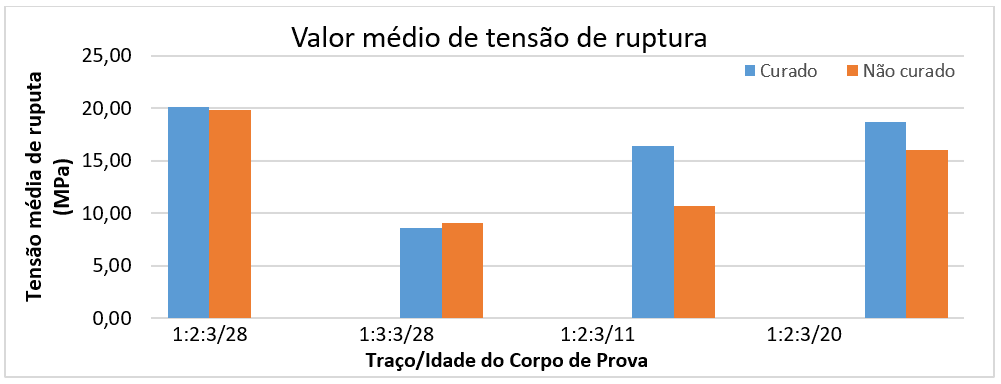

The initial results were obtained from concrete structures, representing a beam and a slab, exposed to outdoor conditions for approximately seven months. During the exposure period of the concrete elements to outdoor conditions, including sun, rain, and wind, two slab elements and one beam element were subjected to the usual curing process in Manaus, which involves cycles of wetting at the beginning and end of the day. The results from axial compression tests are presented in Figure 11, obtained from elements cured by the customary regional process and from specimens without artificial curing. The tests were conducted in February 2022, and the results were randomly selected in pairs for the graph.

Figure 11: Compression strength of cured and uncured concretes

These results show that the strengths of the concretes made with rounded gravel in both situations, exposed to the open air, with and without curing, are practically equal. During the strength gain period of these elements, which encompassed the months from November to February, the relative humidity was around 80%, with a predominance of daily rainfall in the region.

The average stresses in the slabs were 42.9 MPa for elements cured by the wetting process and 42.3 MPa for elements exposed to the open air. In the case of the beam elements, the analysis of reliable values also indicated a small discrepancy in the average stress, namely 36.3 MPa and 34.7 MPa, respectively. It is worth noting that the slab elements have a smaller thickness than the beam elements and are more sensitive to natural factors such as rain, temperature, humidity in the air, and in the soil.

Table 3 shows the rupture stresses obtained in tests of cylindrical specimens of 10 cm x 20 cm at twenty-eight days of age. The metal molds were filled with concrete mixed manually with a hoe, using a mix ratio of 1:2:3 (cement: sand: rounded gravel). Eight circular cylindrical specimens were molded from the same concrete mixture, with four of them immersed in a saturated calcium hydroxide solution, and the others stored in a covered environment.

Table 3: Concrete strength with a mix ratio of 1:2:3

| Condition of the test specimen. |

Ultimate stress (MPa)

|

| Uncured

cured

|

21,0 18,2 18,3 22,0

21,4 24,7 13,8 21,2 |

Source: Author’s own (2022).

A similar procedure was performed for concrete test specimens with a mix ratio of 1:3:3 (cement: sand: rolled gravel), manually mixed and with a high water content in the mixture (water-to-cement ratio greater than 0.6). The compressive strength at twenty-eight days of age is listed in Table 4.

Table 4: Concrete Strength with Mix Ratio 1:3:3

| Specimen Condition |

Rupture Stress (MPa)

|

| Uncured

cured

|

9,4 8,0 9,3 9,5

8,4 8,2 9,5 8,1 |

Source: Author’s own (2022).

In the months of March and April 2022, a period with a high relative air humidity (INMET, 2022), two sets of concrete specimens were cast with a mix of 1:2:3, manually executed with a hoe. From each concrete batch, eight test specimens were molded, with four specimens cured according to the current Brazilian standard and four specimens exposed to the covered environment. The test results for the specimens are provided in Table 5.

Table 5: Concrete Strength with Mix Proportion 1:2:3

|

Test Specimen Condition

|

Rupture Stress (MPa) |

| 11 Days of age 20 Days of age | |

| Not cured 10,9 13,9 10,8 7,3 16,1 15,1 16,0 17,0

cured 19,4 17,4 17,5 11,3 21,4 18,4 16,7 18,2 |

|

Source: Author’s own (2022).

The results shown in tables 3, 4, and 5, presented in the graph in Figure 12, related to tests conducted in the months of February, March, and April 2022, during the rainy season with humidity around 80%, revealed that differences in compression strengths between the two situations begin to emerge.

Figure 12: Average compressive strength of cured and uncured specimens

In the month of July, compressive strengths of concrete at seven days of age were evaluated, molding six cylindrical specimens, 10cm x 20cm, and 15cm x 30cm. The mix of cement, sand, and rolled gravel, proportioned for 20MPa, was performed in a 120-liter capacity concrete mixer. The results obtained in the tests, in MPa, were as follows: a) specimens immersed in a saturated solution of calcium hydroxide: 21.9; 23.6; 21.2, with an average value of 22.2MPa; b) specimens exposed to a covered outdoor environment: 19.6; 20.2; 18.9, with an average value of 19.6MPa. These results indicated a significant drop in the compressive strength values of uncured specimens.

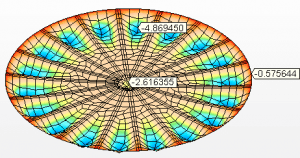

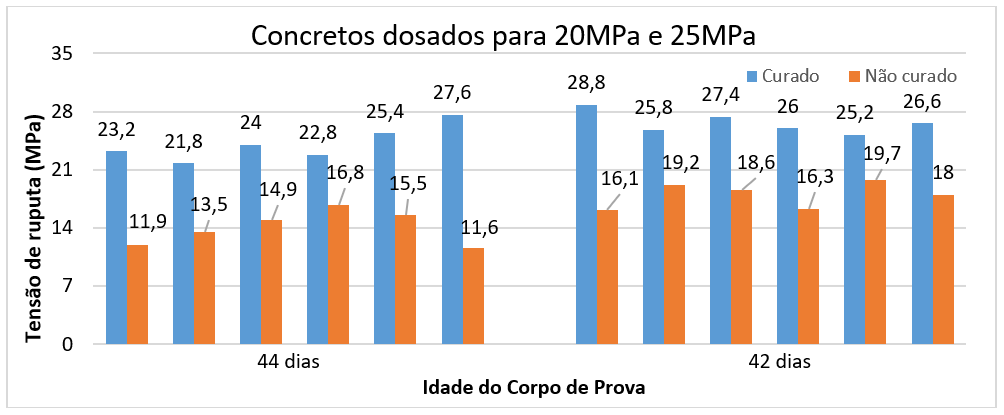

In the months of August and September 2022, two batches of twelve specimens each were molded: six specimens from each batch were exposed to outdoor conditions, subjected to sun, rain, and wind, and six were immersed in a saturated solution of calcium hydroxide. The compressive strength values of randomly selected pairs are shown in Figure 13.

Figure 13: Compressive Strength of Cured and Uncured Test Specimens

The graphical representations of the stresses, figure 13, indicate a strong influence of environmental conditions on the increase in strength of concrete material in the hardening phase. The results showed that low air humidity and high temperature prevent the complete reaction of cement components during the hardening period when the wetting procedure is not continuous.

In the final phase of the tests, the strength evaluations were carried out on concrete designed for 20MPa, using 10cm x 20cm molds, at seven days old, in the following situations: curing following the prescriptions of NBR 5738 (2016) and curing by wetting test specimens exposed to the open air, at the beginning and end of the day. The batch of bodies in the first situation provided the following tensile stresses in MPa: 21.9, 27.3, 20.3, 20.5, 24.0, 23.7, with an average value of 23.0MPa. Tests of the bodies exposed to the open air and cured by wetting cycles provided, in MPa: 21.8, 21.3, 21.2, 21.3, 21.5, 20.3, with an average value of 21.2MPa. The values indicated a strong influence on the gain in strength of concrete material in the phase of its hardening, preventing the complete realization of the reactions of cement components in the mixture of cement, aggregates and water.

5. CONCLUSION

The results of the research showed that the concretes of the works executed in the city of Manaus, in a period known as the Amazon summer, July to November, when the sun’s incidence is stronger and rain is scarce, in general, have compressive strengths below those predicted in the projects. In this period, part of the water contained in the fresh concrete is evaporated, preventing part of the chemical reactions from being completed. The use of usual procedures in the city of Manaus, cycles of wetting of the surfaces at the beginning and end of the day, in the period of low relative humidity of the air, does not allow the containment of the water contained in the mixture of the components of the concrete.

Outside of this period, the usual curing procedures in the city of Manaus do not compromise the strength gains of concretes that have rolled gravel in their composition. According to INMET, 2022, the relative humidity of the air, in this part of the year, oscillates around 80% and the daily temperatures are milder, with alternating periods of rain.

Some builders avoid the escape of water present in the mixture to the environment, following the prescriptions in force in standards: continuous wetting of the surfaces, use of a water film on the slab, spraying of a chemical product on the surface to contain the water constant in the mixture or wrapping the elements with wet blankets.

In works with technological control, concrete provided by a dosing plant and molding of test specimens at the site, the problem of interrupting part of the reactions of the cement components in the mixture, in the period from July to November, persists. The results of the tests do not represent the reality of the work, as the concrete curing processes on the work do not follow the provisions of the standard.

The negative effects of curing by the process of wetting the surface, generally twice a day, cover other parameters of the hardened concrete. The main ones are modulus of elasticity, which depends on the compressive strength of the concrete, and concrete porosity. The increase in porosity, which results from the loss of water to the environment, in the case of reinforced concrete, facilitates the penetration of aggressive gases and water into the material, which can cause corrosion in the reinforcement, as, for example, Helene (1986) and Helene (1988) assure. The intensities of the parameters rotation of cross section and deflection of beams and slabs of buildings, which are inversely proportional to the modulus of elasticity, are also impaired, and may exceed the admissible limits prescribed by standard.

In summary, the prescriptions of Brazilian standards that deal with the design and execution of concrete structures should be adapted for the city of Manaus, State of Amazonas, considering, mainly, the environmental conditions of the region, the type of coarse aggregate, rolled gravel, and the usual curing procedures for concrete used in the region.

BIBLIOGRAPHIC REFERENCES

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR 14931: execução de estruturas de concreto armado, protendido e com fibras: requisitos. Rio de Janeiro: ABNT, 2023.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR 15575 – 1: edificações habitacionais – desempenho: requisitos gerais. Rio de Janeiro: ABNT, 2021.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR 16605: cimento e outros materiais em pó – determinação de massa específica. Rio de Janeiro: ABNT, 2017.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR 16915: agregados – amostragem. Rio de Janeiro: ABNT, 2021.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR 16916: agregado miúdo – determinação da densidade e da absorção da água. Rio de Janeiro: ABNT, 2021.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. (ABNT). ABNT NBR 16917: agregado graúdo – determinação da densidade e da absorção de água. Rio de Janeiro: ABNT, 2021.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR 16972: agregados – determinação da massa unitária e do índice de vazios. Rio de Janeiro: ABNT, 2021.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS(ABNT). ABNT NBR 16973: agregados – determinação de material fino que passa pela peneira 75μm por lavagem. Rio de Janeiro: ABNT, 2021.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR 17054: agregados – determinação da composição granulométrica – método de ensaio. Rio de Janeiro: ABNT, 2022.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR 5738: concreto – procedimento para moldagem e cura dos corpos-de-prova. Versão corrigida: 2016. Rio de Janeiro: ABNT, 2015.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR 6118: projeto de estruturas de concreto – procedimento. Rio de Janeiro: ABNT, 2014.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS(ABNT). ABNT NBR 7211: agregados para concreto – especificação. Rio de Janeiro: ABNT, 2022.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR 7218: agregados: determinação do teor de argila em torrões e materiais friáveis. Rio de Janeiro: ABNT, 2010.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR 7680-1: concreto: extração, preparo, ensaio e análise de testemunhos de estruturas de concreto – resistência à compressão axial. Rio de Janeiro: ABNT, 2015.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). ABNT NBR NM 49: agregado miúdo – determinação de impurezas orgânicas. Rio de Janeiro: ABNT, 2001.

ANDRADE, T.; HELENE, P. Concreto de cimento Portland. Materiais de construção civil e princípios de ciência e engenharia de materiais, São Paulo: 2.ed., cap. 29, p. 945-984, 2010.

AOKI, C. Y., ROCHA, F. S.; FERNANDES, F. F. Influência do agregado graúdo comercializado na cidade de Manaus no desempenho dos elementos de concreto das edificações. In: CONGRESSO BRASILEIRO DO CONCRETO, 57, 2015, Bonito – MS. Anais… São Paulo: IBRACON, 2015.

BRITO, L. V., ROCHA, F. S; FERNANDES, F. F. Influência do agregado miúdo comercializado na cidade de Manaus no desempenho dos elementos de argamassa e concreto das edificações. In: CONGRESSO BRASILEIRO DO CONCRETO, 57, 2015, Bonito – MS. Anais… São Paulo: IBRACON, 2015.

HELENE, P. Corrosão em armaduras para concreto armado. São Paulo: PINI/ IPT, 1986. 45 p.

HELENE, P. Manual prático para reparo e reforço de estruturas de concreto. São Paulo: Pini, 1988. 119 p.

INSTITUTO NACIONAL DE METEOROLOGIA – INMET. Gráfico diário de estações de Manaus (A101). Disponível em: <https://tempo.inmet.gov.br/Graficos/A101>. Acesso em: outubro de 2022.

LIMA, M. G. Ações do meio ambiente sobre as estruturas de concreto. Concreto: ciência e tecnologia, São Paulo, v.1, cap. 21, 2011.

MARCELINO, C. Bairros de Manaus. Disponível em: <http://www.camilomarcelino.com/bairrosmanaus/>. Acesso em 27 de setembro de 2021.

METHA, P. K.; MONTEIRO, P.J. M. Concreto, estrutura, propriedades e materiais. Revisores e Coordenadores: Hasparyk, N. P., Helene, P.; Paulon, A. V. São Paulo: IBRACON, 2008. 674 p.

NEVILLE, A. M.; BROOKS, J. J. Tecnologia do concreto. 2.ed. São Paulo: BOOKMAN, p. 472, 2013.

ROCHA, F. S; COELHO, D. S. P.; SILVA, J. R. S. Influência do seixo rolado no módulo de elasticidade do concreto comercializado na cidade de Manaus. In: CONGRESSO BRASILEIRO DO CONCRETO, 62, 2020, Florianópolis – SC. Anais… São Paulo: IBRACON, 2020.

ROCHA, F. S; FERNANDES, F. F.; MONTEIRO, A. K. C. Avaliação da retração em vigas retas de concreto executadas com agregados comercializados na cidade de Manaus. In: CONGRESSO BRASILEIRO DO CONCRETO, 57, 2015, Bonito – MS. Anais… São Paulo: IBRACON, 2015.

ROCHA, Francisco dos Santos et al. Agregados para argamassa e concreto executados na cidade de Manaus. Manaus: BK Editora, 2017. 57p.

TERZIAN, Paulo; HELENE, Paulo. Manual de dosagem e controle do concreto. São Paulo: PINI/SENAI, 1993. 189 p.

TUTIKIAN, B. F.; HELENE, P. Dosagem dos concretos de cimento Portland. Concreto: Ciência e Tecnologia, São Paulo: v. 1, p. 439–471, 2011.

VALIN JUNIOR, M. O. et al. Influência de diferentes climas urbanos na qualidade do concreto. Engenharia e Construção, Curitiba – PR, v.3, n.1, p. 42-56, jan./jun., 2016.

[1] Advisor. PhD and Master in Structural Engineering from USP, Civil Engineer from the Federal University of Amazonas. ORCID: 0009-0009-6928-6186. CURRÍCULO LATTES: http://lattes.cnpq.br/6406742929195826.

[2] Master’s degree in progress in Materials Science and Engineering, Graduated in Civil Engineering. ORCID: 0000-0003-1109-3778. CURRÍCULO LATTES: http://lattes.cnpq.br/3714131411856225.

Sent: May 18, 2023.

Approved: June 20, 2023.