ORIGINAL ARTICLE

OLIVEIRA, Rodrigo Suzano de [1]

OLIVEIRA, Rodrigo Suzano de. Potentially explosive atmospheres: preventing accidents in the oil industry. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year 09, Ed. 01, Vol. 03, pp. 05-27. January 2024. ISSN: 2448-0959, Acess link: https://www.nucleodoconhecimento.com.br/electrical-engineering/preventing-accidents, DOI: 10.32749/nucleodoconhecimento.com.br/electrical-engineering/preventing-accidents

ABSTRACT

This article presents concepts and real cases, as well as standards and regulations, related to environments with potentially explosive atmospheres, and analyzes the advancement of this topic within the Brazilian oil industry through the analysis of non-conformities found in audits conducted in offshore oil facilities. The main purpose of this study is to identify opportunities for improvement and help disseminate the importance of this topic within the Brazilian territory. As will be presented, this subject is increasingly present in our daily lives, but still suffers from a lack of knowledge by a large portion of industry professionals. Additionally, this work has the potential to contribute to the creation of new measures and assist in the development of protection systems and standards within industrial environments regarding the risks of explosions in potentially explosive atmospheres in the oil industry at the national level.

Keywords: Explosive Atmosphere, Oil Industry, Technical Standards, Accidents.

1. INTRODUCTION

The topic of Explosive Atmosphere is already widely discussed and recognized worldwide, especially in Europe and the USA. The first appearance of the subject in the NEC (National Electrical Code) standard addressing electrical installations in this country occurred in 1923, with the introduction of hazardous area classification concepts in 1931 (Contreras, 2021a). Regarding Europe, the first set of standards on the subject was published in Germany in 1912, with the first concepts differentiating atmospheres with explosive gases and vapors from atmospheres with explosive dust introduced in 1935 (Contreras, 2021b).

In Brazil, the first technical standards on the subject date back to the 1950s and were driven by the advancement of the oil industry in the country, which effectively began around 1930 with the construction of the Riograndense refinery in Rio Grande do Sul. Three other refineries were built in different cities in the country in the 1940s and 1950s, with these being the pioneering installations in the use of electrical equipment for classified areas. In the 1970s and 1980s, there was a huge demand for such equipment due to the discovery of oil in the Campos Basin, in the state of Rio de Janeiro. During this period, several cases of fires and explosions were observed in Brazil, mainly in the oil industry, due to improper construction, installation, and maintenance of these equipments. Faced with this scenario, during the 1990s and early 21st century, regulations and standards began to emerge with the aim of standardizing installations and preventing accidents in areas with explosive atmospheres (Bulgarelli, 2018).

According to an article published in November 2023 by Agência Brasil, data from the Brazilian Institute of Oil and Gas show that Brazil is currently the ninth largest oil producer in the world and the first in Latin America (Moura, 2023). With the increase in oil exploration in Brazilian waters, more and more new offshore units are being put into operation in our country. This also increases the risk arising from environments with potentially explosive atmospheres.

A drilling rig or a production vessel, for example, can actually become a true industrial bomb if several preventive measures are not adopted. Among these measures are precautions related to explosion prevention such as equipment certifications and personnel training (Bulgarelli, 2018). Other examples found in onshore environments (on land) are power plants and refineries.

Numerous examples of explosions in factories and industrial plants are directly associated with this risk. However, since a large portion of the workers involved in these environments still do not have a deep understanding of the subject, these cases end up not being treated properly or even remain hidden behind political and economic interests at the expense of human life protection. As observed by Bulgarelli (2018), for example, one of the existing problems related to the lack of knowledge on the subject is the myth, held by users and manufacturers, that simply using certified equipment meeting existing legal requirements ensures that installations in explosive atmospheres are safe.

This article will present a study on dozens of inspection audit reports in classified areas that were conducted between 2010 and 2020 in various offshore oil units, with the aim of demonstrating the reduction of non-conformities found as new standards were created and new awareness efforts took shape.

It is based on this environment where accidents are still caused by misinformation, despite the advances made, that this work first seeks to contribute to the expansion of knowledge about current technical standards, and secondly, aims to help raise awareness about the risks involved in areas with explosive atmospheres in the oil industry and possible protective measures.

2. LAWS AND STANDARDS

Over decades, standards and regulations have been created to address the subject of ‘explosive atmospheres.’ Currently, there are hundreds of technical standards around the world and dozens of international standards, but increasingly, one specific standard gains strength and recognition. This standard is the European standard known as the IEC standard (International Electrotechnical Commission).

Translating from their website[2], “IEC stands for the International Electrotechnical Commission, an international organization founded in 1906 for the international standardization of electrical, electronic, and related technologies.” (IEC, 2024).

Another well-known standard is the American standard, also called the NEC standard (National Electrical Code). The National Electrical Code (NEC) is a standard adopted for the safe installation of cables and electrical equipment in the United States and is also known by the acronym NFPA 70 (National Fire Protection Association), which is actually a part of the United States National Fire Protection Code (United States, 2023).

In this study, greater emphasis will be given to the European standard as it is also the standard adopted in Brazil, through the ABNT (Brazilian Association of Technical Standards). However, a brief explanation will be given about the NEC classification for the purpose of comparison with the European classification standard.

As defined by ABNT (2020, preface),

A Associação Brasileira de Normas Técnicas (ABNT) é o Fórum Nacional de Normalização. As Normas Brasileiras (NBR), cujo conteúdo é de responsabilidade dos Comitês Brasileiros (ABNT/CB) e dos Organismos de Normalização Setorial (ABNT/ONS), são elaboradas por Comissões de Estudo (CE), formadas pelas partes interessadas no tema objeto da normalização.

Regarding explosive atmospheres, ABNT had published in 1995 the standard NBR 5418 which addressed Electrical Installations in Explosive Atmospheres in Brazil. This standard “established the requirements for the selection and application of equipment, design, and assembly of electrical installations in explosive atmospheres by flammable gases or vapors.” (ABNT, 1995). It and other secondary standards were canceled from the 21st century onwards when ABNT started adopting the IEC standard as the national standard for matters related to explosive atmospheres in the country (Bugarelli, 2017).

Currently, most Brazilian standards related to this topic are part of the NBR IEC 60079 series of technical standards. There are more than 30 different parts within this set of standards that address some specific issue related to electricity in potentially explosive environments.

Three standards (or sub-standards) can be highlighted as the most important when it comes to explosive atmosphere in the oil industry (ABNT NBR IEC 60079, 2020). They are:

– NBR IEC 60079-10, which “is related to the identification and classification of areas where explosive atmospheres of dust and layers of combustible dust are present, in order to allow an adequate evaluation of ignition sources in such areas” (ABNT NBR IEC 60079, 2020).

– NBR IEC 60079-14, which “contains the specific requirements for the design, selection, and assembly of electrical installations in classified areas associated with explosive atmospheres” (ABNT NBR IEC 60079, 2020).

– NBR IEC 60079-17, which is “related to the inspection and maintenance of electrical installations in classified areas, where the risk can be caused by flammable gases, vapors, mists, dust, fibers, or suspended particles” (ABNT NBR IEC 60079, 2020).

As analyzed by Paulo (2018), from the promulgation of Regulatory Standard 10 (NR10), all technical standards published by ABNT dealing with electricity also gained legal force and, therefore, became mandatory.

According to NR10,

Esta norma foi emitida pelo Ministério do Trabalho e Emprego do Brasil e tem por finalidade garantir a segurança e a saúde dos trabalhadores que interagem com instalações e serviços em eletricidade. Esta norma se aplica às fases de geração, transmissão, distribuição e consumo de eletricidade, incluindo as fases de projeto, construção, montagem, operação, manutenção das instalações elétricas, e quaisquer trabalhos realizados nas suas proximidades (Brasil, 2019, p.1).

3. CLASSIFIED AREAS

As defined in the international manual CompEx,

Atmosfera Explosiva é uma mistura de substâncias inflamáveis na forma de gases, vapores, poeiras ou fibras com o ar (ou Oxigênio) que, na presença de uma fonte de ignição e sob determinadas condições atmosféricas, a combustão consegue se propagar e provocar uma explosão. (ASET, 2012, p.23).

And,

“Área Classificada é todo local sujeito à probabilidade de existência ou formação de uma atmosfera explosiva” (ASET, 2012, p.25).

Normally, process equipment and systems such as manholes, covers, sample points, flanges, vents, drains, etc., are highly regarded as sources of risk due to the probability of product leakage into the environment where they are installed. Such risk sources are then classified into grades, according to the duration and frequency of explosive atmospheres to be generated by these sources. As defined by ABNT NBR 60079 (2020), sources that generate risk continuously or for long periods are known as continuous grade sources. Primary grade sources are those that, during normal operating conditions, generate risk periodically or accidentally. Secondary grade sources are those that generate risk for a short period under operating conditions outside of the design.

As an example of a continuous grade risk source, we have the interior of a flammable tank, where there is a permanent presence of the explosive mixture due to the product inside the tank. In the same tank, its vent constitutes a primary grade risk source as it is potentially an outlet for product vapors when its level rises; that is, it is not something that happens permanently but can occur when the level rises. Still in this same example, secondary grade risk sources would be the flanges, which can leak due to gasket aging, loosening of bolts, or a possible loss of level control, resulting in liquid spillage into the containment area (ASET, 2012).

3.1 DEFINITIONS OF TYPES OF ZONES FOR GASES AND VAPORS

According to ABNT NBR 60079 (2020), there are three types of zones for mixtures of explosive gases and vapors:

Zona 0 – Local onde a ocorrência de mistura inflamável/explosiva por gases ou vapores é contínua ou existe por longos períodos.

Zona 1 – Local onde a atmosfera explosiva está presente de forma ocasional e em condições normais de operação, sendo normalmente geradas por fontes de risco de grau primário.

Zona 2 – Local onde a atmosfera explosiva está presente somente em condições anormais de operação e persiste somente por curtos períodos de tempo, sendo geradas normalmente por fontes de risco de grau secundário.

3.2 DEFINITIONS OF TYPES OF ZONES FOR DUSTS AND FIBERS

According to ABNT NBR 60079 (2020), there are three types of zones for mixtures of explosive dusts and fibers:

Zona 20 – Local em que a atmosfera explosiva, em forma de nuvem de poeira, está presente de forma permanente, por longos períodos ou ainda frequentemente. Estas zonas, igualmente em gases e vapores, são geradas por fontes de risco de grau contínuo.

Zona 21 – Local em que a atmosfera explosiva em forma de nuvem de pó está presente em forma ocasional, em condições normais de operação da unidade. Estas zonas, igualmente em gases e vapores, são geradas por fontes de risco de grau primário.

Zona 22 – Local onde a atmosfera explosiva em forma de nuvem de pó existirá somente em condições anormais de operação e se existir será somente por curto período de tempo. Estas zonas, igualmente em gases e vapores, são geradas por fontes de risco de grau secundário.

3.3 CLASSIFICATION OF AREAS ACCORDING TO NEC STANDARD

The American standard does not divide areas into zones like the IEC. It encompasses two divisions (United States, 2023):

Divisão 1: Locais com alta probabilidade de presença de mistura inflamável.

Divisão 2: Locais com baixa probabilidade de presença de mistura inflamável.

The table below shows the correlation between the IEC classification and the NEC classification:

Table 1 – Comparison between IEC and NEC on Area Classification

| COMPARISON OF IEC CLASSIFIED AREAS (ZONES) X DIVISIONS (NEC) | |||

| IEC | ZONE 0 / ZONE 20 | ZONE 1 / ZONE 21 | ZONE 2 / ZONE 22 |

| NEC | DIVISION 1 | DIVISION 2 | |

Source: Jordão, 2002.

3.4 CLASSIFICATION OF FLAMMABLE PRODUCTS

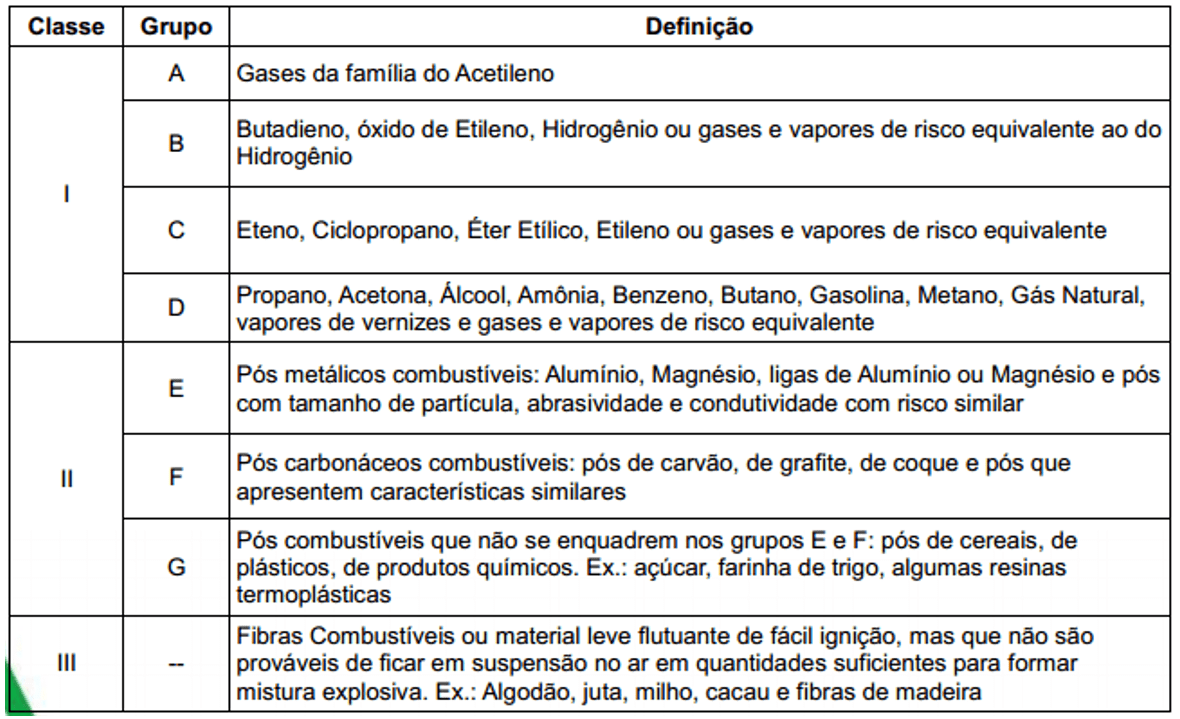

The environment can be classified according to the substance present in it, following the API (American Petroleum Institute) and NEC (National Electrical Code) standards, being divided into classes as shown in Table 2 and subdivided into gas groups, as shown in Table 3.

Table 2 – Classes of Flammable Substances (NEC)

| Class | I | II | III |

| Substance | Gases and Vapors | Dusts | Fibers |

Source: ASET, 2012.

Table 3 – Groups of Flammable Substances (NEC)

As defined in the NEC (United States, 2023), “grouping also means a grading of risk, where group A gases have the greatest destructive effect and group D gases have the least destructive effect.”

Both the international IEC standard and the Brazilian ABNT standard do not classify the environment into classes, but into groups, which are organized based on the electrical equipment used, as shown in the following table.

Table 4 – Groups and Subgroups of Flammable Substances (IEC and ABNT)

| Groups | Subgroups | Typical Substance | Application/Definition |

| Group I | I | Methane | Electrical equipment for use in mines susceptible to the formation of firedamp |

| Group II | IIA | Propane | Equipamentos elétricos para uso em locais com atmosferas de gases explosivos |

| IIB | Ethylene | ||

| IIC | Hydrogen | ||

| Group III | IIIA | Combustible particles in suspension | Electrical equipment for use in locations with combustible dust atmospheres |

| IIIB | Non-conductive dust | ||

| IIIC | Conductive dust |

Source: Jordão, 2002.

In the IEC ABNT classification, the sequence of risk in each group, from highest to lowest degree, is: C → B → A. That is, equipment designed for subgroup IIC can be used in subgroups IIB and IIA, as well as equipment designed for subgroup IIIC can be used in subgroups IIIB and IIIA. The subgroup ending with A is the lowest risk group, and equipment designed for this subgroup can only be used for it (ABNT NBR IEC 60079, 2020).

The following table shows a comparison made between American and international standards regarding the classification of gases.

Table 5 – Comparison of Explosive Gas Subgroups between IEC and NEC standards

| Acetylene Group | Hydrogen Group | Ethene Group | Propane Group | Mine Gases (Methane) | |

| API/NEC | Group A | Group B | Group C | Group D | – |

| ABNT/IEC | Group IIC | Group IIC | Group IIB | Group IIA | Group I |

Source: The Author, 2024.

3.5 SURFACE TEMPERATURE

Alongside the classification of areas (zones and divisions) and groups (mines, gases, and dusts) and subgroups of materials, a third classification is imperative to achieve a complete and accurate classification of an environment with the potential for the presence of an explosive atmosphere. This classification pertains to the maximum surface temperature that equipment can reach in a given area.

The ignition points of each material define temperature classes so that the surface temperature of the equipment never exceeds these values, thus spontaneous ignition is avoided (ASET, 2012). The table below shows the standardized temperature classes by IEC and NEC.

Table 6 – Comparison of Temperature Classes between IEC and NEC Standards

| Maximum Surface Temperature (°C) | NEC | IEC/ABNT |

| 450 | T1 | T1 |

| 300 | T2 | T2 |

| 280 | T2A | |

| 260 | T2B | |

| 230 | T2C | |

| 215 | T2D | |

| 200 | T3 | T3 |

| 180 | T3A | |

| 165 | T3B | |

| 160 | T3C | |

| 135 | T4 | T4 |

| 120 | T4A | |

| 100 | T5 | T5 |

| 85 | T6 | T6 |

Source: The Author, 2024.

4. TYPES OF PROTECTION AND RISK CONTROL MEASURES

Currently, various types and concepts of protection and risk control measures are found in the market. However, great care must be taken when choosing the most suitable ones for each occasion, especially concerning internationally built offshore installations.

There is, however, unanimity on this subject, which is the fact that, whenever possible, the first measure to be adopted is the area’s declassification. That is, making a given area safe or preventing the possibility of the presence of an explosive atmosphere.

The following are nine types of protections that can be used when it is not possible to avoid the existence of a classified area and their respective definitions exactly as described in the ABNT NBR 60079 standard (2020).

4.1 EXPLOSION PROOF – EX D (EXPLOSION PROOF OR FLAME-PROOF)

This type of protection can be used in zones 1 and 2. As defined in ABNT NBR 60079 (2020),

Invólucro à prova de explosão é um sistema suficientemente resistente e vedado para não propagar uma explosão, e cuja temperatura superficial não provoque a ignição de uma atmosfera explosiva. Isto implica uma construção robusta, com tampas roscadas ou parafusadas. Esses invólucros são construídos de forma a resistir mecanicamente à pressão após a ocorrência da ignição da mistura dentro dele, impedindo que a explosão se propague para o meio externo.

4.2 INCREASED SAFETY – EX E (INCREASED SAFETY)

This type of protection can be used in zones 1 and 2, as defined in ABNT NBR 60079 (2020).

Equipamento elétrico de segurança aumentada é aquele que sob condições normais de operação não produz arcos, faíscas ou aquecimento suficiente para causar ignição da atmosfera explosiva para a qual foi projetado, e no qual são tomadas as medidas adicionais durante a construção, de modo a evitar com maior segurança, que tais fenômenos ocorram em condições de operação e de sobrecarga previstas.

4.3 PRESSURIZED EQUIPMENT – EX P (PRESSURIZED)

This type of protection can be used in zones 1 and 2, as defined in ABNT NBR 60079 (2020),

Neste tipo de proteção uma pressão positiva superior à pressão atmosférica, é mantida no interior do invólucro de modo a evitar a penetração de uma atmosfera explosiva que venha a existir ao redor do equipamento.

Pressurized equipment is grouped into three categories and their function is to reduce the classification within the pressurized enclosure, resulting in the reduction of:

– Zone 1 or Group I to unclassified with the use of px protection;

– Zone 1 to Zone 2 with the use of py protection; and

– Zone 2 to unclassified area with the use of pz protection.

4.4 ELECTRICAL EQUIPMENT IMMERSSED IN OIL – EX O (OIL IMMERSION)

This type of protection can be used in zones 1 and 2, as defined in ABNT NBR 60079 (2020),

O equipamento elétrico é imerso em óleo de tal modo que não inflame uma atmosfera inflamável acima do líquido ou na parte externa do invólucro. Este tipo de proteção é aplicável somente para equipamentos fixos.

4.5 EQUIPMENT IMMERSED IN SAND – EX Q (POWDER-FILLED)

This type of protection can be used in zones 1 and 2, as defined in ABNT NBR 60079 (2020),

Neste tipo de proteção as partes que podem inflamar uma atmosfera explosiva são imersas por um material de enchimento de modo a evitar a ignição de uma atmosfera explosiva externa. Este tipo de proteção só se aplica a equipamentos com corrente nominal menor ou igual a 16A; que consumam potência menor ou igual a 1000VA cuja tensão de alimentação não seja superior a 1000V.

4.6 ENCAPSULATED ELECTRICAL EQUIPMENT – EX M (ENCAPSULATION)

This type of protection can be used in zones 1 and 2. As defined in ABNT NBR 60079 (2020), ‘parts that can cause ignition are encapsulated in resin so as not to ignite an external explosive atmosphere.

4.7 INTRINSICALLY SAFE EQUIPMENT – EX I (INTRINSIC SAFETY)

This type of protection can be used in: ‘ia’ – Zone 0; ‘ib’ – Zones 1 and 2; and ‘ic’ – Zones 1, 2, and 3. As defined in ABNT NBR 60079 (2020), ‘they are those which under normal conditions (i.e., circuit opening and closing) or abnormal conditions (short-circuit, earth fault) do not release enough energy to ignite the explosive atmosphere.’

Furthermore, according to ABNT NBR 60079 (2020), such devices are grouped into three categories: ‘ia’ – designed not to cause ignition in normal operation or in the event of two simultaneous faults in the environment; ‘ib’ – incapable of causing ignition in normal operation or in the event of a fault in the environment; and ‘ic’ – incapable of causing ignition in normal operation.

4.8 NON-INCENDIVE ELECTRICAL EQUIPMENT – EX N (NON-INCENDIVE)

This type of protection can be used in zone 2. As defined in ABNT NBR 60079 (2020), ‘they are equipment that, under normal operating conditions and under specified abnormal conditions, do not cause ignition of the explosive gas atmosphere existing in the environment’.

5. CERTIFICATION AND MARKING OF EQUIPMENT

Each country has its own regulations and legislations for the use and manufacture of equipment for explosive atmospheres.

In Brazil, these regulations and legislations are established by Conmetro (National Council of Metrology and Industrial Standardization), an agency subordinate to the Ministry of Justice. As determined by Inmetro (National Institute of Metrology, Quality and Technology) Ordinance No. 115 of 2022, all equipment must be certified for use in classified areas, whether or not they are manufactured in the country.

Certification is coordinated by Inmetro, which uses ABNT (Brazilian Association of Technical Standards) as the basis for creating technical standards that cover all types of protections.

Inmetro also accredits laboratories that verify through tests and analyses whether the equipment complies with the recommendations of technical standards and whether they are truly suitable for installation in locations with potentially explosive atmospheres (Inmetro, 2022).

For intrinsic safety, for example, the only accredited laboratory for national tests until 2014 was Labex, located in the laboratory center of Cepel in Rio de Janeiro. As further noted by Bulgarelli (2019), five years later, in 2019, Labelo – Laboratories Specialized in Electrical and Electronics, located at PUC (Pontifical Catholic University) of Porto Alegre / RS, became the first Brazilian laboratory for tests for explosive atmospheres recognized internationally by IECEx (International Electrotechnical Commission System).

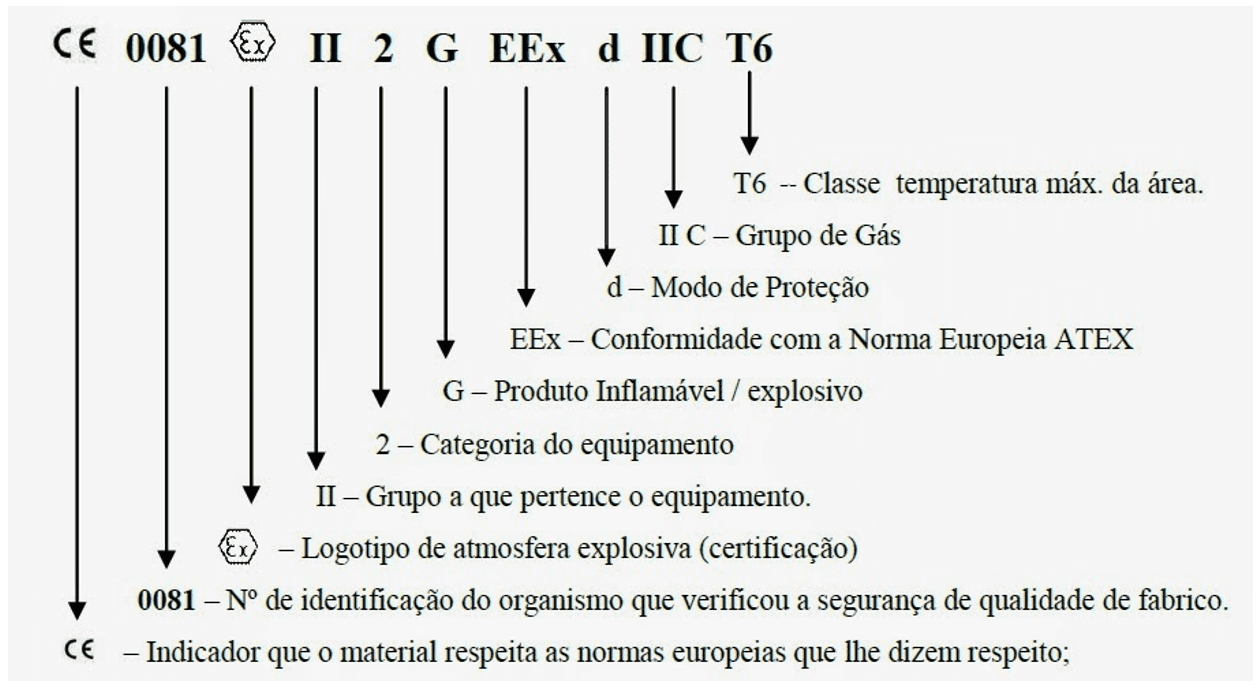

Certified equipment or equipment produced in certified factories receive what we call an Ex marking, which is nothing more than the identity of the equipment, listing the type of protection and the conditions of use. An example of this marking is illustrated in figure 1 below. By norm, every equipment installed in a classified area must have, clearly and visibly, an identification plate containing its classification information as well as the number of its certificate of conformity (Jordão, 2002).

Figure 1 – Ex marking for certified equipment

6. STUDY OF NON-COMPLIANCES AND EVOLUTION IN THE OIL INDUSTRY

Over the years, dozens and even hundreds of accidents have occurred in environments with potentially explosive atmospheres, such as mines, refineries, pharmaceutical industries, offshore platforms, and so on. Below, some of the most important accidents in world history will be presented to gauge the relevance of this subject in our daily lives and help understand how they occurred so that similar accidents can be avoided in the future. The results of the study of non-conformities from audits conducted between 2010 and 2020 on offshore units will also be presented, comparing them with the advancement of standards within the oil industry.

6.1 MAJOR ACCIDENTS

In October 1913, the Senghennydd coal mine disaster occurred in Wales, resulting in 439 deaths. This disaster was considered one of the worst in a coal mine in the history of the United Kingdom and, in terms of loss of life, was one of the most serious worldwide. According to Lieven (1994), “the accident is believed to have been caused by the explosion of methane gas ignited by electrical sparks from equipment, possibly an electric bell.” The coal dust on the floor inside the mine was lifted by the gas explosion, creating a cloud of coal dust that caused a second explosion, subsequently lifting even more coal dust and causing consecutive explosions. This was one of the earliest accounts of such a major accident of this nature and helped in the recognition and study of the risk of ignition of vapors, dust, or potentially flammable clouds caused by sparks from electrical equipment.

In 1984, a gas leak during well drilling followed by an explosion on the Enchova platform operating in the Campos Basin left 37 dead and 23 injured. During the evacuation, one of the steel cables of the lifeboat in which workers were attempting to escape became entangled, and the other snapped, causing the boat to fall from a height of 30 meters. In 1988, a condensate gas leak formed over the Piper Alpha platform in the North Sea, igniting and causing a massive explosion. Secondary fires in the oil caused by the initial explosion melted the gas supply pipeline, leading to another explosion that engulfed the entire platform and resulted in the deaths of 167 people (United Kingdom, 1990).

Other accidents in Brazil related to human or equipment failures in Explosive Atmospheres include the explosion of the P36 in the Campos Basin with 11 deaths in 2001, the fire on the Namorado platform also in the Campos Basin with six injured people in 2014, and the explosion at the Landulpho Alves refinery with three injured in 2015 (O Globo, 2015).

6.2 STUDY OF NON-COMPLIANCES IN OIL PLATFORMS AND SHIPS

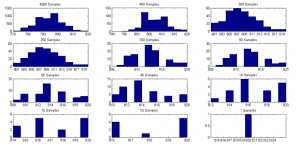

For this study, data on non-conformities from audits of classified areas conducted on dozens of ships and oil platforms between 2010 and 2020 were compiled. A total of 4125 items were analyzed in 55 reports obtained from different facilities. The data were classified into three groups, which will be compared with the evolution of standards and regulations in their areas. These data show the percentage of non-conformities found for each group.

Table 7 – Percentage of Non-Conformities from Audits in Classified Areas

| Type of Non-Conformity | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

| Equipment and Installations | 50 | 34 | 38 | 16 | 5 | 3 | 3 | 2 | 5 | 0 | 0 |

| Procedures | 66 | 62 | 23 | 5 | 1 | 2 | 2 | 0 | 0 | 0 | 1 |

| Personnel Training | 95 | 71 | 62 | 52 | 41 | 5 | 3 | 3 | 4 | 1 | 2 |

Source: The Author, 2024.

As can be seen, the total number of non-conformities has been decreasing over the years. The group that evolved most rapidly was Procedures, while the group that showed slower progress was Personnel Training. As will be shown next, this result is directly related to the advancement of standards and regulations focused on this topic.

6.3 ADVANCEMENT OF STANDARDS AND LEGISLATIONS

As seen, standards and regulations for Explosive Atmospheres began to emerge in Brazil during the 1990s and early 21st century, due to the recurring accidents within the oil industry amplified by the discovery of oil in the Campos Basin (Bulgarelli, 2018).

However, the dissemination and adherence to these new standards did not occur immediately. As shown by audit data from oil installations, these standards initially had an effect on the management procedures to be implemented.

Two events contributed to increasing pressure regarding compliance with standards for Classified Areas in the oil industry: the discovery of the pre-salt layer at the end of 2006 and the regulatory milestone approved in 2010. After the approval of the regulatory milestone (BBC, 2019).

NR-10 underwent a major revision in 2004 to meet the needs of the oil industry, especially regarding Explosive Atmospheres. In this revision, for example, mandatory 8-hour training for personnel working in Classified Areas was included, and this same personnel’s training was to be conducted by a qualified professional as described in the regulation (Rausch, 2011). However, it was only in 2015 that the first accredited training centers emerged to carry out this work. This fact is aligned with the findings in the study on non-conformities, which show a drastic decrease in non-conformities related to personnel training from 2015 onwards.

A large group of Ex standards focused on equipment and installations were published by ABNT between 2005 and 2011, with over ten published in just one year (Bulgarelli, 2011). Similarly, it can be seen that the numbers of non-conformities decreased considerably around the year 2012.

7. CONCLUSION

Based on this article, it is evident that there is still a need for improvement regarding the treatment and prevention of accidents related to the risks involved in activities carried out in environments with potentially explosive atmospheres, especially in the oil industry.

The technical concepts presented and the facts related to accidents in the oil industry suggest that, despite considerable progress in compliance with standards, protective measures such as training and qualification are still relatively recent and require additional work to effectively contribute to accident prevention.

Brazil has evolved regarding this topic since the first large-scale offshore oil industry operations emerged, but the most significant advances occurred only in the first two decades of the 21st century. Companies and other entities have joined forces in recent years through committees to review and develop new standards focused on this topic.

The results of the assessment conducted on non-conformities from audits of offshore oil installations show progress at different times for the three groups studied, and such advances occurred as new standards were created and effectively implemented in the country.

In conclusion, advances in standards and regulations for explosive atmospheres have occurred over the years, primarily focused on the oil industry, which, due to its economic weight, has dictated the pace of investment in this area. It is also concluded that the lack of awareness about the standards remains higher among workers and suppliers compared to the managers involved in the subject, highlighting the need for additional measures.

REFERENCE

ABNT NBR IEC 60079 (séries). Atmosferas Explosivas: conceitos gerais, características, instalações, inspeções e manutenções. Associação Brasileira de Normas Técnicas, 2020.

ABNT NBR 5418. Instalações Elétricas em Atmosferas Explosivas. Associação Brasileira de Normas Técnicas, 1995.

ASET – International Oil & Gas Training Academy. CompEx Manual. Sixth Edition, 2012.

BBC. Euforia, crise e megaleilão: os altos e baixos do pré-sal. BBC, 2019. Disponível em: https://www.bbc.com/portuguese/brasil-50311115. Acesso em: 04 jan. 2024.

BRASIL. Ministério do Trabalho e Emprego. Norma Regulamentadora No. 10. (NR-10) – Segurança em Instalações e Serviços em Eletricidade. Portaria SEPRT 915, de 30/07/2019.

BULGARELLI, Roberval. Evolução, atualização e aplicação das normas técnicas da ABNT. O Setor Eletrico, 2011. Disponível em: https://www.osetoreletrico.com.br/wp-content/uploads/2011/06/Ed64_fasc_instalacoesEX_cap29.pdf. Acesso em: 04 jan. 2024.

BULGARELLI, Roberval. Novos requisitos para instalações elétricas em atmosferas explosivas. O Setor Eletrico, 2017. Disponível em: https://www.osetoreletrico.com.br/novos-requisitos-para-instalacoes-eletricas-em-atmosferas-explosivas-2/. Acesso em: 25 nov. 2023.

BULGARELLI, Roberval. O mito da segurança proporcionada somente pelos equipamentos “ex” certificados parte 1/2. Maex Engenharia, 2018. Disponível em: https://maex.com.br/o-mito-da-seguranca-proporcionada-somente-pelos-equipamentos-ex-certificados-parte-1-2/. Acessado em: 24/11/2023.

BULGARELLI, Roberval. Primeiro LABORATÓRIO BRASILEIRO de ensaios de equipamentos para atmosferas explosivas reconhecido pelo internacionalmente pelo IECEx. O Setor Eletrico, 2019. Disponível em: https://www.osetoreletrico.com.br/primeiro-laboratorio-brasileiro-de-ensaios-de-equipamentos-para-atmosferas-explosivas-reconhecido-pelo-internacionalmente-pelo-iecex/. Acesso em: 24 nov. 2023.

CONTRERAS, Mirko Torrez. A not too brief history of the origins of the EX standards. Part I: The NEC Code. Linkedin, 2021a. Disponível em: https://www.linkedin.com/pulse/too-brief-history-origins-nec-atex-iecex-standards-torrez-contreras/. Acesso em: 24 nov. 2023.

CONTRERAS, Mirko Torrez: A not too brief history of the origins of the EX standards. Part II: The ATEX Directive. Linkedin, 2021b. Disponível em: https://www.linkedin.com/pulse/too-brief-history-origins-nec-atex-iecex-standards-ii-mirko/. Acessado em: 24 nov. 2023.

ESTADOS UNIDOS. NFPA 70, National Electrical Code (NEC). NFPA, 2023.

IEC: About Us. IEC, 2024. Disponível em: https://www.iec.ch/about-us. Acesso em: 22 dez. 2023.

INMETRO: Portaria nº 115 – Requisitos de Avaliação da Conformidade para Equipamentos Elétricos para Atmosferas Explosivas. Portaria INMETRO, 2022.

JORDÃO, Dácio de Miranda. Manual de Instalações Elétricas em Indústrias Químicas, Petroquímicas e de Petróleo – Atmosferas Explosivas. 3ª edição. Editora: Qualitymark, 2002.

LIEVEN, Michael. Senghennydd: The Universal Pit Village, 1890-1930. Editora : Gomer Press, 1994.

MOURA, Bruno de Freitas. Brasil tem recorde de produção de petróleo e gás em setembro. Rio de Janeiro: Agência Brasil, 2023. Disponível em: https://agenciabrasil.ebc.com.br/economia/noticia/2023-11/brasil-tem-recorde-de-producao-de-petroleo-e-gas-em-setembro#:~:text=De%20acordo%20com%20o%20Instituto,ordem%2C%20s%C3%A3o%20os%20tr%C3%AAs%20principais. Acesso em: 20 dez. 2023.

O GLOBO: Lembre os principais acidentes da Petrobras. O Globo, 2015. Disponível em: https://oglobo.globo.com/economia/lembre-os-principais-acidentes-da-petrobras-15310164. Acesso em: 30 out. 2023.

PAULO, José Manuel de Abre. A legalidade dos requisitos de segurança em instalações e serviços em eletricidade (NR 10 e normas técnicas correlatas). JUS, 2018. Disponível em: https://jus.com.br/artigos/68915/a-legalidade-dos-requisitos-de-seguranca-em-instalacoes-e-servicos-em-eletricidade-nr-10-e-normas-tecnicas-correlatas. Acesso em: 15 dez. 2023.

RAUSCH, Sérgio. NR-10 exige capacitação em atmosferas explosivas. Universidade Abracopel, 2011. Disponível em: https://abracopel.org/download/nr-10-exige-capacitacao-em-atmosferas-explosivas/?doing_wp_cron=1705517845.1219439506530761718750. Acesso em: 05 jan. 2024.

REINO UNIDO. The Public Inquiry into the Piper Alpha Disaster. Health and Safety Executive, 1990. Disponível em: https://www.hse.gov.uk/offshore/piper-alpha-disaster-public-inquiry.htm. Acesso em: 20 nov. 2023.

APPENDIX – FOOTNOTE

2. “Founded in 1906, the IEC (International Electrotechnical Commission) is the world’s leading organization for the preparation and publication of international standards for all electrical, electronic, and related technologies.” (IEC, 2024).

[1] MBA in Project Management from Fundação Getúlio Vargas in Rio de Janeiro, Postgraduate degree in Occupational Safety Engineering from Universidade Candido Mendes in Campos dos Goytacazes, Bachelor’s degree in Electrical Engineering with emphasis on Automation from Universidade Santa Úrsula in Rio de Janeiro. ORCID: 0009-0007-7812-0538. Currículo Lattes: http://lattes.cnpq.br/3997154402798015.

Material received: January 11, 2024.

Material approved by peers: January 18, 2024.

Edited material approved by authors: January 26, 2024.