CASE REPORT

CORREIA, Walter Franklin Marques [1], EPSZTEJN, Ruth [2], ALMEIDA, Hugo Leonardo Nascimento [3], OLIVEIRA, Rodrigo Alves [4], QUEIROZ, Júlia Carla de [5], MURAD, Karine [6]

CORREIA, Walter Franklin Marques. et al. Let’s Play? Safeguarding! Improving Safety Assessment Processes for Children’s Products with a Focus on Quality Infrastructure through Design. Revista Científica Multidisciplinar Núcleo do Conhecimento. Year. 08, Ed. 09, Vol. 02, pp. 22-30. September 2023. ISSN: 2448-0959, Access link: https://www.nucleodoconhecimento.com.br/production-engineering/lets-play-safeguarding, DOI: 10.32749/nucleodoconhecimento.com.br/production-engineering/lets-play-safeguarding

ABSTRACT

The act of playing is as inherent to human nature, especially in its early stages, as learning to walk. Numerous children’s products are released each year to the market at a rapid pace, and given such speed, safety concerns can be easily overlooked, which would otherwise be thoroughly analyzed, monitored, and tested. In this perspective, this case study aims to assist in the risk reduction process of children’s products, taking into consideration, among others, Ordinance INMETRO/ME – No. 302 of 07/12/2021, which presents conformity assessment requirements for toys.

Keywords: Children’s products, Safety, Toy regulation.

1. INTRODUCTION

“A brincadeira é o trabalho da infância”.

Jean Piaget

Studies focused on consumer product accidents in Brazil are still recent and appear incipient and timid within the academic and business community. Similarly, the same can be said regarding children’s products. Although the numbers related to accidents with such products are still small or insignificant in comparison to the estimated dimension, in a comparative analysis with other countries, this assertion is reinforced. This is evident when comparing the quantity of reported consumer accidents in Sinmac – Inmetro’s Consumer Accident Monitoring System, which was 3,416 between 2016 and 2022. In contrast, in the USA, the number of records in NEISS – National Electronic Injury Surveillance System was 323,345 in 2022 (CPSC, 2022). It is noticeable that within this context, there is a gap to be closed, considering the presumably alarming amount of consumer accidents that may exist in Brazil.

According to the Consumer Product Safety Commission – CPSC (2022), the number of injuries caused by toys in 2022 in the USA amounted to 180,953 injured individuals treated in the emergency departments of 96 American hospitals (including children’s hospitals). In contrast, only 6% (3 accident reports) of valid reports in Sinmac are related to the Inmetro theme (Inmetro, 2022) for the same year and subcategory of children’s products, highlighting the disparity in accident records between the two. In this context, it can be presumed that the quantity of consumer accidents with toys in Brazil is much higher than the quantity of reported cases in Sinmac. This discrepancy may stem from unfamiliarity with Sinmac and other causes to be investigated.

As pointed out by Mtengi et al (2019), playing is extremely important for child development, and certainly, toys provide fun, entertainment, and contribute to a significant portion of this learning. However, sometimes, a product, no matter how simple it may seem, can affect this audience and put them at risk. Playing is one of the rights guaranteed by the ECA – Statute of the Child and Adolescent (BRAZIL, 1990), and doing it safely is more than a necessity and right for the child audience—it is the duty of the industry and society.

This article presents an ongoing case study within the scope of the INMETRO Technical and Scientific Cooperation Agreement signed between the National Institute of Metrology, Quality, and Technology – Inmetro and the Federal University of Pernambuco – UFPE. The study aimed to verify the possibility of expanding Inmetro’s market surveillance actions and, consequently, reducing the availability of unsafe products in the market, focusing on toys initially. The study takes as a reference Portaria INMETRO / ME – number 302 of 2021 for children’s products (toys).

2. MARKET SURVEILLANCE

“As crianças não brincam de brincar. Brincam de verdade”.

Mario Quintana

In general, regulation is a tool through which the State interferes with the behavior of the involved parties, aiming to drive improvements in efficiency, safety, economic growth, and even benefits for social well-being (BRAZIL, 2018). One way to carry out regulation is through standardization, which occurs by issuing a mandatory document or technical regulation. This regulation defines the necessary criteria for the manufacturing, importing, or national marketing of a product, also encompassing pertinent administrative provisions (INMETRO, 2015).

Market surveillance aims to verify if the regulation is being correctly implemented and if products offered in the market maintain safety requirements. Inspection is one of the ways to carry out market surveillance. For Inmetro, inspection consists of verifying if the regulated product presents mandatory information and displays the conformity identification seal, as established by the regulation, or if the products display such a seal improperly without Inmetro authorization (INMETRO, 2015).

Inspection of intrinsic aspects utilizes visual inspections, measurements, or laboratory testing to verify if the mandatory intrinsic requirements of a product remain when it is being commercialized. In both cases, in both inspection and verification, suppliers who violate the regulations are subject to penalties stipulated by Law 9933/1999 (BRAZIL, 1999).

Currently, Inmetro does not have a laboratory infrastructure to carry out the inspection of intrinsic aspects, considering the breadth of objects that can be inspected. The existence of a laboratory infrastructure in the states to provide technical support for this activity is crucial to fulfilling the institutional mission. The signing of the Inmetro-UFPE Cooperation Agreement enabled the development of a methodology and the execution of tests at LACA2I – Laboratory of Conception and Analysis of Intelligent Artefacts, which facilitated the execution of the inspection of intrinsic aspects of toys (products regulated by Inmetro) intended for 0 to 3 years.

3. [A BIT] ABOUT DESIGN SCIENCE RESEARCH (DSR)

“Educar é contar histórias. Contar histórias é transformar a vida na brincadeira mais séria da sociedade”.

Augusto Cury

Design Science Research (DSR) is a methodology or research toolbox with the objectives of developing an artifact to solve a practical problem in a specific context and to generate new technical and scientific knowledge. Considering that the design of an artifact should be based on behavioral aspects, these aspects generate possibilities related to the learning process, work, relationships, communication, etc., conducted by people within the context of a given problem (DRESCH, 2015).

DSR, working in conjunction with User Experience Analysis (where the observation and evaluation of users’ activities during the use of certain products are carried out), can broaden the spectrum of implementation and applicability of the artifact, serving as an optimized method that can be analyzed within a specific context, such as an adaptation of a well-established methodology to the reality imposed by the market/project.

Within this scope, meeting a conception of a methodological support framework aimed at evaluation systems, implementation, and development of technical and laboratory infrastructure involving the safety of children’s products in the context of inspecting intrinsic aspects becomes a fundamental part when the purpose is to ensure that requirements and evaluation foundations in these types of artifacts and scope are prioritized.

4. METHODOLOGY: FROM MODELING TO PRINTING FOR TESTING

“Toda criança tem o direito de brincar e ser criança na forma mais simples de ser”.

Marianna Moreno

A metodologia utilizada para o desenvolvimento do projeto piloto foi baseada no DSR juntamente com a verificação da norma ABNT NBR NM 300-1/2004 – Versão corrigida de 2011, com as etapas a seguir.

4.1 IDENTIFICATION OF THE PRODUCT TO BE TESTED

Based on the information contained in the Sinmac INMETRO infographics (2022), the item Toy/Children’s Products appears as one of the items with the most reports of consumer accidents from 2006 to 2022. Considering the experience of LACA2I at UFPE and the necessary tests for the intrinsic aspect inspection process related to the norm, especially items 5.2 Small Parts Tests and 5.3 Test for shape and sizes of certain toys, according to the aforementioned ordinance approving the Technical Regulation of Quality and Conformity Assessment Requirements for Toys – Consolidated and the item’s availability in the market, it was agreed that the product to be initially tested for intrinsic aspect inspection would be a toy. Based on the necessary infrastructure for conducting the test, it was defined that the small parts test would initiate the INMETRO project (2015).

4.2 MODELING AND PRINTING OF TEMPLATES FOR TESTS

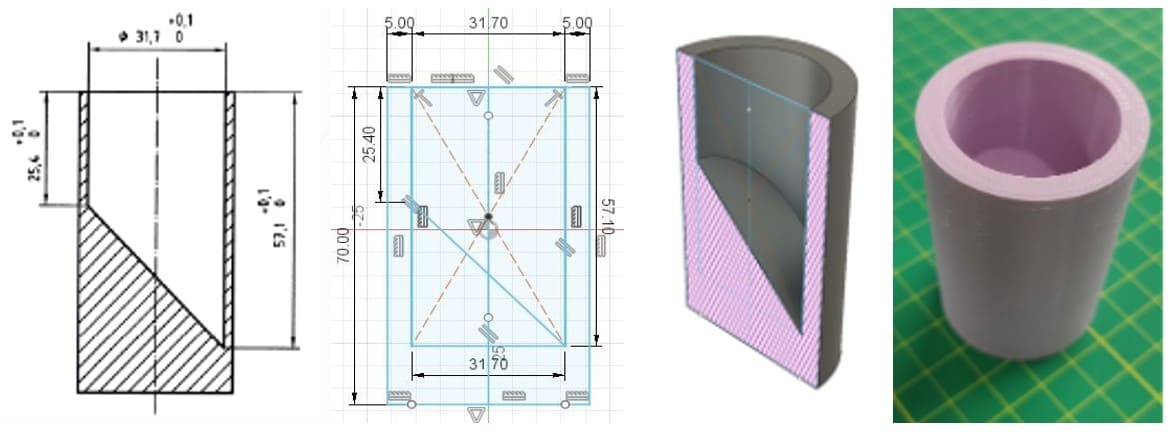

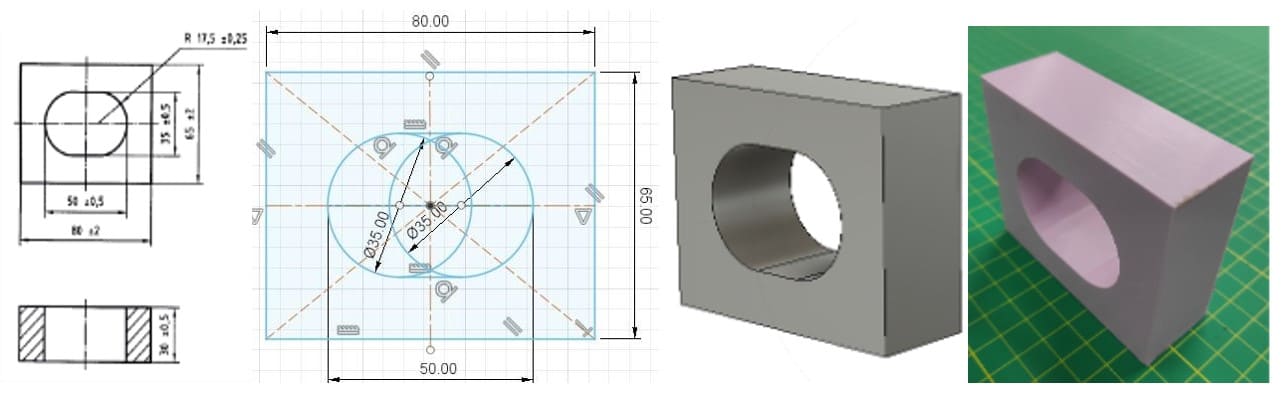

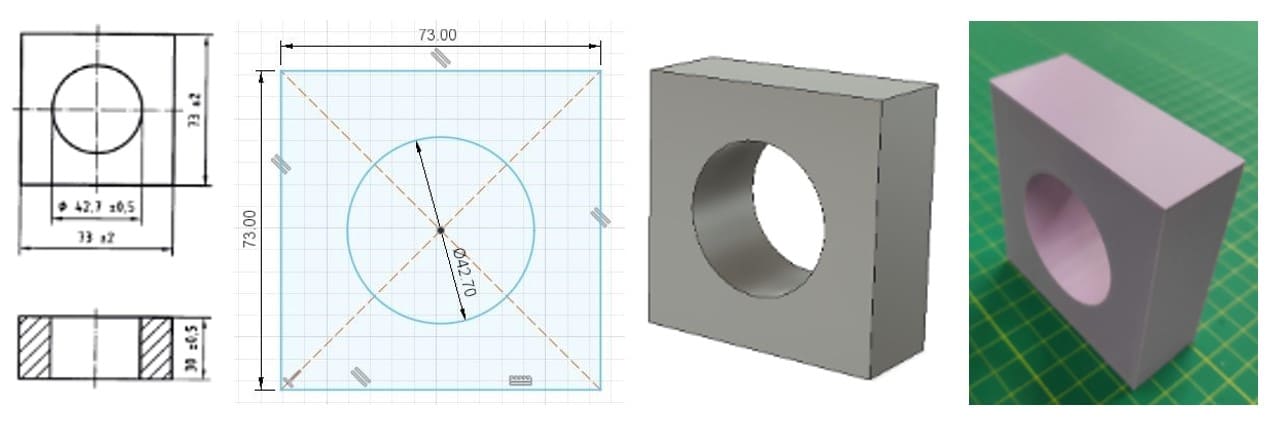

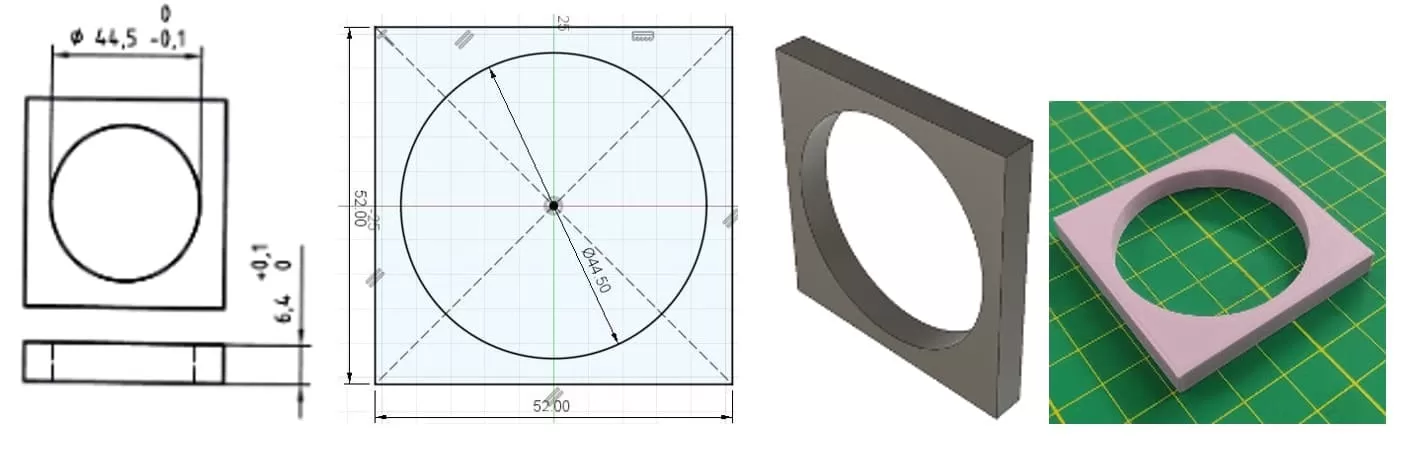

The conception of the items went through 03 stages: transposition of models with respective real-scale dimensions in 3D modeling software, exporting the models in a format compatible with slicing software, and printing the models.

The process started with Fusion 360 software (Autodesk) for modeling and exporting in “STL binary” format. Subsequently, the file was sent to CURA slicing software (Ultimaker) – where the GCODE file was prepared for printing – using the following settings: layer height 0.2mm, infill 20% with Zig-Zag pattern, printing speed of 40mm/s, travel speed of 100mm/s, retraction of 1.5mm, nozzle temperature 210°C, bed temperature 60°C, and PLA filament. Due to the characteristics of the parts, supports were not needed. The CURA printing settings were not modified.

For development, an Ender 3 PRO 3D printer with a 0.4 mm nozzle was used, and modifications were made to achieve Direct Drive characteristics by replacing the Bowden-type tube. Additionally, the main board was replaced with a newer version, resulting in better printing quality and final results. It’s important to note that these changes are not mandatory to facilitate the printing of the presented models. These details are provided as reference information about the equipment. The following Figures (1 to 16) should be understood as follows, from left to right: (i) reference image of the standard, (ii) dimension transcriptions, (iii) visual/virtual representation of the 3D model, and (iv) printed model. All parts were measured after printing for compliance with the standard.

Figures 1 to 4 – Small Parts Cylinder from item 5.2 Small Parts Test

Figures 5 to 8 – Test Template A for item 5.3 Testing for shape and size of certain toys

Figures 9 to 12 – Test Template Sup. B for item 5.3 Testing for shape and size of certain toys

Figures 13 to 16 – Test Template C for item 5.4 Ball Testing

The models above were not only printed, measured (with calibrated equipment), tested, and validated, but also 8 additional sets were made and sent to Inmetro-RJ for distribution to other agencies and institutes to apply the same described procedures. These have been appropriately utilized by the other agencies. The sets were sent by Inmetro to the IPEMs – Institutes of Weights and Measures, in Acre, Amazonas, Rondônia, Santa Catarina, Ceará, Bahia, and São Paulo. It is emphasized that this action aims to expand the quantitative reach of tests to be conducted by Inmetro in the country, as few laboratories and agencies perform this type of test in the partnership and agreement format as in the present case.

4.3 TEST EXECUTION

A total of 27 certified toys were tested. All information regarding each one was included in the technical reports sent to Inmetro along with the test data. As indicated by Inmetro itself, an inspector from IPEM-PE was present during all tests. The methodology followed what is provided in the aforementioned standard for the items listed above, taking into account elements such as the positioning of the parts in relation to the template, age range (up to 18 months inclusive or from 19 to 96 months inclusive), types of falls to be executed, and the type of template to be used in the test.

For the tests, a Canon PowerShot SX170IS digital camera and a conventional tripod were used, always following the same procedure:

- Recording of the seal for registration;

- Recording of the Collection Form (data);

- Recording of the opening of the sealed package and the product packaging;

- Recording of each part of the product;

- Recording of the tests.

For each of the products collected and delivered by IPEM-PE to LaCA2I, another sample for retesting (if necessary) was also collected and remained in the possession of IPEM-PE, and the same procedures as per the mentioned standard were followed for all samples. The following presents the presentation and analysis of the tested products.

Figures 17 to 43 – 27 Tested toy samples

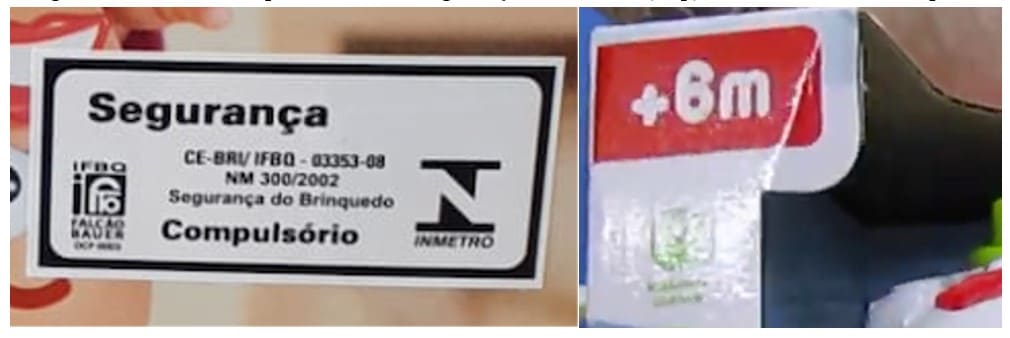

Regardless of the toy typology, each one went through essentially the same procedures, from filming to testing. For each of these, it was possible to highlight in the individual reports each of the safety seals from Inmetro and the age identification, as shown in the examples in Figures 44 and 45 below. The age group was important for the correct identification of the characteristics of the conducted test.

Figures 44 and 45 – Example of Inmetro Safety Seal (left) and Age Range of the toy.

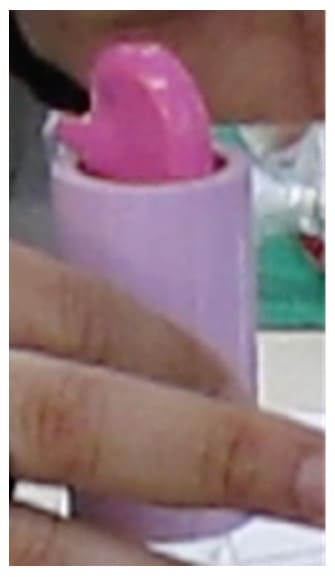

As mentioned, for each of the pieces, a Small Parts Test was conducted using the templates according to the standard and the relevant Regulation, as shown in Figures 4, 8, 12, and 16 presented earlier. The following image aims to illustrate an example of part of the test:

Figure 46 – Piece/part of one of the toys being tested on the Small Parts Test Template according to ABNT NBR NM300-1 standard

The tests within the templates occurred both before the drop test and after the drops when there was any identified loose part. For each of the tests, it was necessary to let the piece enter naturally, meaning the force applied to the toy was solely due to its own mass, with gravity being the only acting force, as specified by the standard.

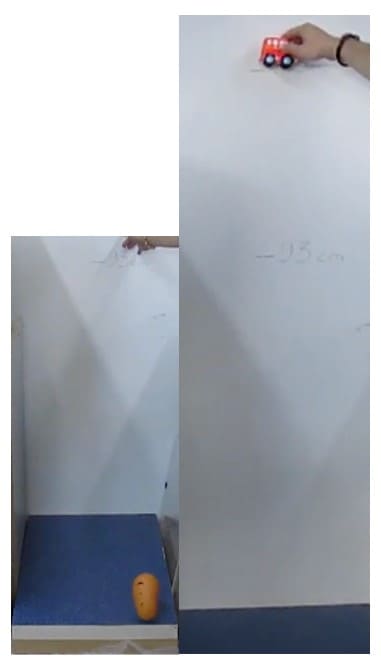

For the drop tests, according to item 5.25.2 – Drop Test of the mentioned standard, a test base with vinyl tiles over concrete was used following the standard specifications. Drop tests were conducted from both 138 cm and 93 cm heights, for ages up to 18 months and below 1.4 kg with 10 drops for the first, and from 19 to 96 months inclusive below 4.5 kg with 4 drops for the second. Figures 47 and 48 below aim to illustrate this stage for each height.

Figures 47 and 48 – Example records of drop tests for two toys at different heights

During the tests, with proper documentation, out of the 27 samples, only one resulted in ‘non-compliance,’ meaning the sample does not meet the standard. To safeguard legal matters, the brand was left unidentified. However, as can be seen in the following images (Figures 49 and 50), after one of the drops, one of the toys broke into several parts, and these easily fit into the small parts template, rendering the sample ‘non-compliant’ due to a choking hazard:

Figures 49 and 50 – Example records of ‘non-compliance

5. CONCLUSIONS

“Nós não paramos de brincar porque envelhecemos, mas envelhecemos porque paramos de brincar”.

Oliver Holmes

The Design as a mediating agent in the above process enabled the development of protocols, replication of test templates, and their execution. The toy manufacturer with ‘non-compliance’ was notified by Inmetro, and the process proceeded within the relevant legal procedures, potentially leading to the product’s removal from the market.

Considering that the procedure occurred as expected without any complications, it is evident that this type of application model can be followed by other laboratories across the country. However, it still requires verification, and this laboratory is already available to assist in this process. This type of action can assist organizations like Inmetro in mitigating the lack of accredited laboratories for conducting these types of tests. Future work following this research could include:

– Development and conduct of other different tests from the current ones, necessary for monitoring intrinsic aspects of toys, such as traction tests on plush toys.

– Training of technical teams from other laboratories that will conduct small parts tests to monitor intrinsic aspects of toys.

– Application of the developed methodology to other products in the children’s sector to enhance child safety assurance, such as: infant walkers, school articles, cribs, children’s bicycles, feeding chairs, among others.

Conducting tests on various regulated products in the children’s sector by Inmetro will allow LaCA2I to become a reference laboratory in the area of children’s product safety. This experience can be replicated in other states, forming a network of testing laboratories for children’s safety, contributing to ensuring the availability of safer children’s products in the market.

The prospect of having this kind of support for organizations like Inmetro and IPEMs is more than just meeting market or industry demands; it is about safety and the possibility of saving lives because we are not here for mere play.

REFERENCES

ABNT NBR NM 300-1:2004 Versão corrigida. Segurança de brinquedos – Em Vigor. Parte 1: Propriedades gerais, mecânicas e físicas, 2011.

BRASIL. Lei nº 8.069, de 13 de julho de 1990. Dispõe sobre o Estatuto da Criança e do Adolescente e dá outras providências, 1990.

BRASIL. Lei no 9.933, de 20 de dezembro de 1999. Dispõe sobre as competências do Conmetro e do Inmetro, institui a Taxa de Serviços Metrológicos, e dá outras providências, 1999.

BRASIL. Diretrizes Gerais e Guia Orientativo para Elaboração de Análise de Impacto Regulatório – AIR, 2018.

CPSC – Consumer Product Safety Commission. NEISS Data Highlights – Calendar Year 2022. cpsc.gov, 2022. Disponível em: <https://encr.pw/Ux1Iw>. Acesso em: 12 jun 2023.

DRESCH, A.; LACERDA, D. e JÚNIOR, J. Design Science Research: método de pesquisa para avanço da Ciência e Tecnologia, Editora Bookman, 2015.

INMETRO. Portaria n° 248, de 25 de maio de 2015. Disponível em: http://www.inmetro.gov.br/legislacao/pai/pdf/PAI000182.pdf. Acesso em: 12 junho 2023

INMETRO. Sinmac – relatório 2022. Disponível em: https://l1nk.dev/3MCmc. Acesso em: 12 jun 2023.

MTENGI, B. et al. Design of an Enhanced Hit the Target Game. Proceedings of the 2019 2nd International Conference on Electronics and Electrical Engineering Technology, ACM, pp. 37–41, 2019.

[1] Advisor. PhD in Production Engineering – UFPE with a Sandwich Period at the Universidade Técnica de Lisboa (UTL) in Portugal (2007), Master’s in Production Engineering – UFPE (2002), Specialist (Lato Sensu) in Ergonomics – UFPE (2001), and Bachelor’s in Industrial Design with a focus on Product Design from UFPE (1999). ORCID: https://orcid.org/0000-0002-6491-9783. Currículo Lattes: http://lattes.cnpq.br/3252289006108114.

[2] Holds a degree in Production Engineering from the Federal University of Rio de Janeiro (1977), a master’s in Production Engineering from the Federal University of Rio de Janeiro (1988), and a Ph.D. in Production Engineering from the Federal University of Rio de Janeiro (1998). ORCID: https://orcid.org/0000-0002-0405-9566. Currículo Lattes: http://lattes.cnpq.br/6204685444781546.

[3] Professional Master’s in Design. Center for Studies and Advanced Systems of Recife, CESAR (2018), Specialization in Planning and Strategic Management. Centro Universitário Internacional, UNINTER (2016), and Bachelor’s in Computer Science from UFPE (2015). ORCID: https://orcid.org/0000-0003-4467-0113. Currículo Lattes: http://lattes.cnpq.br/9433837114578364.

[4] Specialization in Teaching at Full-Time Schools – UFRPE (2015), Bachelor’s in Design – UFPE (2019), Bachelor’s in Computer Science Education – Distance Learning. UFRPE (2013), 2011 Technical/Professional Course – IFPE (2011). ORCID: https://orcid.org/0009-0009-6904-2093. Currículo Lattes: http://lattes.cnpq.br/4854317996725963.

[5] Master’s in Design from UFPE (2014), Bachelor’s in Home Economics from UFRPE (2010), and Technical/Professional Course in Quality from SENAC/RS (2009). ORCID: https://orcid.org/0009-0007-9767-3269. Currículo Lattes: http://lattes.cnpq.br/3005274073461488.

[6] MBA in Production and Service Management Technologies (INT in partnership with Trilha Projetos), and Bachelor’s in Production Engineering from UFF. ORCID: https://orcid.org/0000-0003-4126-980x. Currículo Lattes: http://lattes.cnpq.br/7119115218704148.

Submitted: June 20, 2023.

Approved: August 16, 2023.