ORIGINAL ARTICLE

CARVALHO, Ludimila da Silva [1], RIBEIRO, Kiany Richelli Silva [2], EVANGELISTA, Edivania Rocha da Silva [3], ANCKEN, Jeisiel Von [4], GUIRALDELLI, Braz Lucas Olhier [5], ALVES, Wenderli [6], SANTOS, Alexsander Saves dos [7]

CARVALHO, Ludimila da Silva. Et al. Construction of a Rotary Dryer and applicability in sugar drying. Revista Científica Multidisciplinar Núcleo do Conhecimento. 04 year, Ed. 09, Vol. 05, pp. 85-100. September 2019. ISSN: 2448-0959, Access link:

SUMMARY

Over time, due to the increasing and rapid demand for food products, it was necessary to create production techniques. One of them is the method of drying food made by mechanical systems. Thus, the present work aimed to make a small-scale rotary dryer. Behind, tests were performed with wet sugar samples proving operability through laboratory analyses.

Key words: Unit operations, drying, rotary dryer.

INTRODUCTION

Over time, due to the increasing and rapid demand for food products, it was necessary to create production techniques. One of them is the method of drying food made by mechanical systems.

Drying is part of numerous unit operations carried out by the industry, since, respectively, this operation has become the most usual.

According to McCabe; Smith; Harriott (1993), unit operations are steps that make up a process, each step is called operation and can be applied to both physical and chemical processes. Such operations are studied by engineering and are based on science and experience. According to the same authors, a number of principles and techniques are necessary for the treatment of unit operations.

“Among many other purposes, unit operations aim to reduce the size of solids to be processed, separate components from mixtures, or heat and cool solids and fluids. Examples are filtration, drying” […](GOMIDE, 1983, p.3).

According to Foust et al., (1982), drying is the passage of a liquid present in a wet solid to an unsaturated gaseous phase. According to the same authors, dry solids are very valuable products in the industry.

Usually drying is the last operation of a number of other processes, and the original dryer product is ready for packaging (MCCABE; SMITH, MR. SMITH; HARRIOTT, 1993).

The drying operation offers numerous advantages, such as increased product life, ease of transport and marketing, because dry food is light, losses reduction after harvest, besides being unnecessary to specialized labor (CELESTINO, 2010).

Evaporation differs from drying, while at first water is removed as steam at its boiling point, in drying the water is removed as air vapor (GEANKOPOLIS, 1993).

As reported by Gava (1998), it is only possible to develop microorganisms in favorable environments such as adequate humidity rate, temperature, among others. Thus, the drying process is characterized as a method of food conservation, because it reduces moisture so much that microorganisms cannot multiply.

In his studies, Mujumdar (2006) concludes that two phenomena occur when a wet solid is exposed to the drying process, the transfer of energy, mainly in the form of heat and the transfer of internal moisture to the surface part of the solid.

Materials such as organic solids retain moisture inside the fibers or in internal pores. So that the movement of moisture in this situation occurs by diffusion of the liquid through the structure of the solid (FOUST et al., 1982).

The moisture content varies according to the type of product, for example, Danish salt usually contains 0.5% water, coal 4% and most food products contain up to 5% (GEANKOPOLIS, 1993).

There are two basic drying methods, natural drying and artificial drying.

Natural drying is the simple exposure of food to the sun. Suitable for regions with an average temperature of 35ºC to 40°C and low pollution rates (CELESTINO, 2010).

Also according to Celestino (2010), artificial drying is defined by the use of equipment in which the food is, and the dehydration process occurs for a certain period.

Mujumdar (2006) reports the existence of more than 400 types of artificial dryers, but slightly more than 100 are commonly used.

Coulson and Richardson (2005) developed a study where they classify dryers using some variables, such as the physical state of food (liquid, paste, wet solid), solid transport method, heating system (conduction, convection, radiation). In a brief summary, most stationary dryers such as the dryer the tray performs the drying activity by driving, in addition, the direct heating rotary dryers perform the process by convection, and on the other hand, the rotary dryers of indirect heating performs the process by driving.

One of the most used dryers is the tray dryer (MUJUMDAR, 2006).

According to Foust et al., (1982), the tray dryer is a discontinuous operation equipment, formed by a chamber, where the material to be dried is placed on trays or trays.

Another type of dryer is the rotary dryer, consisting of a cylindrical tube slightly inclined towards the outlet, and the material to be dried, usually granular solids for this type of dryer, moves through the tube when it rotates (GEANKOPOLIS, 1993).

Inside the rotary dryers, suspending parts are fixed along the pipe in order to promote the cascading of solids to the outlet flow rate. In these dryers, the heating medium supplied comes from combustion gases, or overheated steam or electricity-heated air (FOUST et al., 1982).

Also according to Foust et al., (1982), the retention time of solids in rotary dryers is of extreme interest. Therefore, it takes a certain time for the gas or drying air to permeate the entire material completing the drying process.

Depending on the application, the rotary dryer can be made in direct and indirect heating and parallel flow or countercurrent.

In direct heating, hot gas or air passes directly over the food. In indirect heating the heat source is isolated from the material to be dried by metal pipes or walls (MUJUMDAR, 2006).

In countercurrent flow dryers, the feed is fixed in the opposite direction to the air stream, in contrast to parallel flow dryers, the air current and the feed move in the same direction.

GOALS

Design a small-scale rotary dryer.

Monitor the drying system using wet sugar samples and analyze the data obtained.

MATERIALS AND METHODS

In the development of the rotary dryer, the following materials related in Table 1 were used.

Table 1: Materials used and costs.

| Materials | Unit | Amount | UNIT VALUE | TOTAL VALUE |

| WASHER 1/4 | Pcs | 11 | R$ 0.10 | R$ 1.10 |

| STAINLESS FLAT BAR 1/4 | M | 1,5 | R$6.66 | R$9.99 |

| PVC CAP 6” | Pcs | 2 | R$ 15,00 | R$ 30,00 |

| STAINLESS STEEL SHEET T 3/16 | M² | 0,40 | R$ 5,00 | R$ 2,00 |

| EXPANDED STAINLESS STEEL SHEET 3/16 | Pcs | 0,30 | R$ 40,00 | R$ 12,00 |

| KEY ON AND OFF | Pcs | 3 | R$ 15,00 | R$ 45,00 |

| COOLER 110V | Pcs | 1 | R$ 20,00 | R$ 20,00 |

| 20-TOOTH CROWN | Pcs | 3 | R$ 15,00 | R$ 45,00 |

| 46-TOOTH CROWN | Pcs | 1 | R$ 12,00 | R$ 12,00 |

| MOTORCYCLE CHAIN 80 CM | Pcs | 2 | R$ 10,00 | R$ 20,00 |

| CUTTING DISC 2 SCREENS 4 1/2” x 1/8 x 7/8 | Pcs | 3 | R$ 16,00 | R$ 48,00 |

| DESBASTE DISC 4 1/2” x 1/4 x 7/8 | Pcs | 2 | R$ 22,00 | R$ 44,00 |

| WELDING ELECTRODES | Kg | 0,50 | R$ 25,00 | R$ 12,50 |

| HAIR ROTATING BRUSH 1000 W | Pcs | 1 | R$ 170,00 | R$ 170,00 |

| FLEXIBLE WIRE | M | 10 | R$ 0.82 | R$ 8,20 |

| FREQUENCY INVERTER | Pcs | 1 | R$ 75,00 | R$ 75,00 |

| Mdf | M² | 1,50 | R$ 25,00 | R$ 37,50 |

| USED WASHING MACHINE MOTOR 0.5 HP | Pcs | 1 | R$ 29,00 | R$ 29,00 |

| SCREW 1/4 BY 2” | Pcs | 11 | R$ 0.35 | R$ 3.85 |

| SUPERB SCREW 5 x 50mm | Pcs | 60 | R$ 0.35 | R$ 21,00 |

| NUT 1/4 | Pcs | 11 | R$ 0.15 | R$ 1.65 |

| SPEED REDUCER 1 x 60 | Pcs | 1 | R$ 200,00 | R$ 200,00 |

| Bearing | Pcs | 4 | R$ 10,00 | R$ 40,00 |

| LATHE AND WELDING SERVICES | Pcs | 1 | R$ 60,00 | R$ 60,00 |

| DIGITAL THERMOMETER | Pcs | 1 | R$ 10,00 | R$ 10,00 |

| LATEX INK | L | 1,0 | R$ 12,00 | R$ 12,00 |

| SPRAY PAINT | Pcs | 3 | R$ 20,00 | R$ 60,00 |

| STAINLESS STEEL TUBE 1 1/4” | M | 0,10 | R$ 15,00 | R$ 1.50 |

| STAINLESS STEEL TUBE 1 1/2” | M | 0,40 | R$ 20,00 | R$ 8,00 |

| STAINLESS STEEL TUBE 5” | M | 0,50 | R$ 35,00 | R$ 17,50 |

| STAINLESS STEEL TUBE 6” | M | 0,20 | R$ 40,00 | R$ 8,00 |

| PVC TUBE 6” | M | 0,25 | R$ 15,00 | R$ 3.75 |

| Total | R$ 1068.54 |

Source: The authors.

The equipment used in this work was based on a direct heating and countercurrent flow rotary dryer located at the Coruripe plant in the municipality of Carneirinho-MG.

For the making of the dryer, cut 500mm of 5″ stainless steel tube, 2 6″, 6″ stainless steel tube 100mm parts, 6″ 1 1/4″ stainless steel tube 100mm, 6″ 3 500mm pvc tube flat bars, ¼” 500mm long, 2 plates 3/16″ in the form of a 6″ diameter circle, 2 plates T 3/16 of 200mm, 20mm thick MDF sheet with 930 x 780mm, 2 MDF plates of 20mm thickness with 930 x 110mm and 2 MDF plates of 20mm thickness with 780 x 110mm.

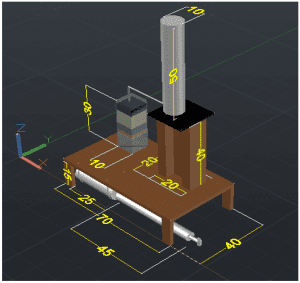

For the construction of the drum, the 5” stainless steel tube was used. Then, 3 flat bars of ¼ were welded internally to the drum, forming the inner vanes of the dryer, as shown in image 1.

Image 1: Reeds inside the drum.

Next to the drum, the 6” tube was coupled at the ends of each side. After that, a round cut was made in the stainless steel tube of 1 ½” forming the inlet flow of the product at the top and the hot air outlet flow on the side, according to image 2. The piece was welded at one end.

Image 2: Product inlet flow at the top of the part and hot air outlet flow on the left side.

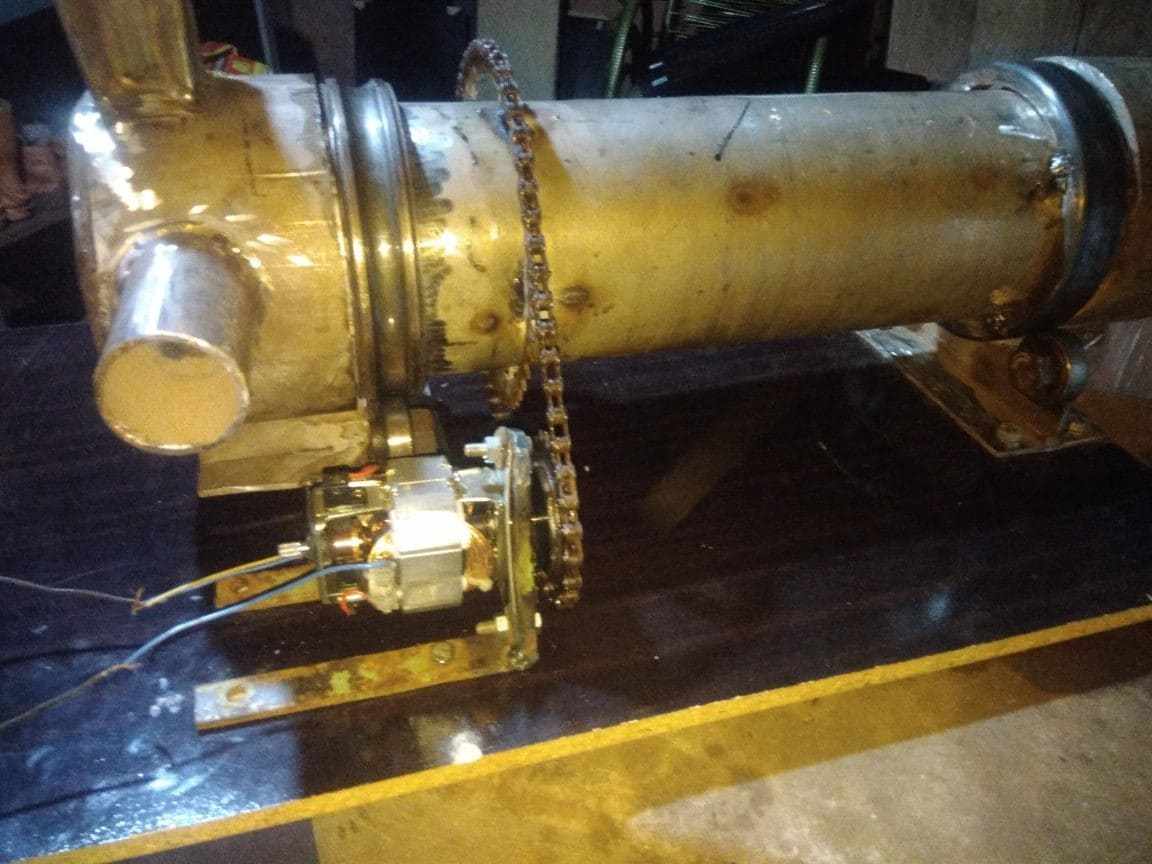

Similarly, externally, a crown of 46 teeth was welded to the drum, as shown in image 3, and 2 bearing support rails on the base made in the lathe, as shown in image 4.

Image 3: Crown of 46 teeth welded to the drum.

Image 4: Bearing support rails

At the opposite end of the product inlet flow, the 1 ¼” 100mm stainless steel tube was welded, forming the hot air inlet, according to image 5.

At the same point, just below the pipe, is the output flow of the product.

Image 5: Hot air inlet tube and product outlet flow.

In the base of the dryer, two 20cm T 3/16 plates were used, where 4 bearings were installed, 2 at the inlet and 2 at the outlet, between a distance of 41cm.

For the heat source, we used the resistance of a 1000 W rotating hair brush, which was later installed to the hot air inlet tube, as shown in image 6.

Image 6: Rotating brush installed.

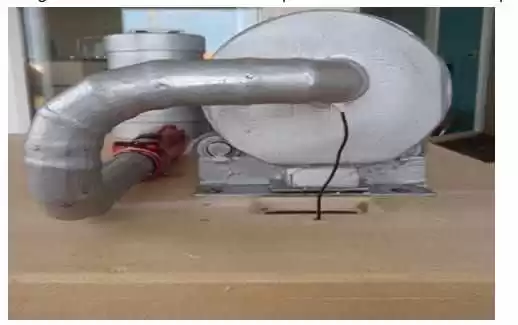

Then, an extractor hood was made with the 6″ PVC tube of 250mm in length, using 2 cap. to cover the two nozzles of the tube and inserted a cooler on the hood, this in turn, installed to the hot air outlet tube, according to image 7.

Image 7: Hood installed to the system.

A 930 x 780 x 110mm MDF base was built, where holes were drilled to screw the dryer, motor, power switch and thermometer.

The motor and reducer were installed on the side of the dryer, as shown in image 8.

Image 8: Motor (right) and reducer (left) installed.

In this sequence, in the motor pulley, a crown of 20 teeth balanced in the lathe was used, fixed to the motor axis, then the current of 80cm was placed.

Finally, the motor and reducer were covered with MDF support and the entire dryer structure was properly painted.

Image 9: Round dryer finished.

EXPERIMENTAL RESULTS

The first and second tests were performed in order to define which engine would perform best in terms of drum rotation. Initially, the engine chosen was the 200w fan motor, which after installing and turning it on, it was noticed that the power was insufficient to move the drum.

In the second test, still with the dryer empty, the engine chosen was the washing machine engine of 0.5PS. Soon, it was noticed that the engine reached the expected result that was to move the drum, but the speed with which the drum rotated was very high and this would hinder the drying process.

In the third test, a speed reducer connected to the motor was introduced to the system to decrease the drum rotations, however, for better adjustment a frequency inverter was also inserted resulting in a rotation of 30 rpm.

After completing the mechanical elements of the mill, the tests were carried out with samples of wet sugar, more precisely, the raw sugar, acquired through donation.

In this project, solids are entered manually.

In the first test, 1kg of sugar was used at a temperature of 81°C. After 1 minute, 10g of the product was removed for moisture analysis. Initially the sugar contained 1.07% moisture and soon after the process the humidity dropped to 0.15%.

In the second test, a larger amount of sugar was used, more precisely, 4.5 kg under a temperature of 88°C for 30 seconds. The moisture analysis was performed with 10g of the product and it was known that at the beginning the moisture content was 0.32% and after drying it decreased to 0.15%, thus, it is can be calculated the drying speed in this process.

Beforehand, the drum area was calculated:

A= 2π.r.(r+h)

A= 2π.0,0635.(0,0635+0,5)

A= 0,224826507m2

Therefore, the drying speed is:

R= Ws.dx/A.dϴ

R= (0,010).(3,2×10-3 – 0,0015)/0,224826507.30

R= 2,52×10-6m/s

CONCLUSION

The constructed rotary dryer presented a good performance from the point of view of sugar drying, preserving the physical and nutritional properties of the food.

Analyzing the various tests, it was noticed that the limited knowledge related to mechanics made it difficult to develop the dryer, since complementary devices such as the speed reducer and the frequency inverter were needed to adjust the drum rotations, and in the industry these assisting devices are not necessary for the functionality of the dryer in question.

Regarding the drying speed, the dryer as such proved to be efficient, drying the sugar almost instantly, considering the results obtained in the calculations.

It is noted that the proposed objective was achieved, considering that the raw sugar should contain between 0.10% and 0.15% of moisture, and through the analyses carried out in the laboratory, the respective contents can be found.

REFERENCES

CELESTINO, SONIA MARIA COSTA. Princípios de secagem de alimentos, 1.ed. (edição online). Planaltina, DF: Embrapa Cerrados, 2010. Disponível em: https://ainfo.cnptia.embrapa.br/digital/bitstream/item/77765/1/doc-276.pdf. Acesso em: 07/01/2019.

FOUST, A; S.; WENZEL, L. A.; CLUMP, C. W.; MAUS, L.; ANDERSEN, L. B. Princípios das operações unitárias. Tradução por Horácio Macedo. 2.ed. Rio de Janeiro: LTC, 1982.

GAVA, ALTANIR. J. Princípios de tecnologia de alimentos, 1.ed. São Paulo: Nobel, 1998.

GEANKOPOLIS, CHRISTIE. J. Transport processes and unit operations, 3.ed. New Jersey: Prentice-hall, 1993.

GOMIDE, REYNALDO. Operações unitárias, operações com sistemas sólidos granulares, 1.ed. São Paulo: Edição do autor, 1983, p.3.

Informe técnico – Parâmetros de qualidade do açúcar e amarelecimento no armazenamento. Mídia Digital. Disponível em: www.ceagesp.gov.br/wp-content/uploads/2015/01/palestra.danilo.tostes.pdf. Acesso em: 10/07/2019.

MCCABE, W. L.; SMITH, J. C.; HARRIOTT, P. Unit operations of chemical engineering, 5.ed. Singapore: Mc Graw Hill, Inc. 1993.

MUJUMDAR, A. S. Manual de secagem industrial, 1.ed. Singapore: Taylor & Francis Group, LLC. 2006.

SINNOTT, R. K. Chemical engineering design, Coulson & Richardson’s chemical engineering series, 4.ed. Reino Unido: Elsevier Butterworth Heinemann, 2005, vol.6.

[1] Academic in Chemical Engineering.

[1][2] Academic in Chemical Engineering.

[1][3] Academic in Chemical Engineering.

[4] Bachelor of Chemistry from Universidade Brasil (2012) / Academic of Chemical Engineering.

[5] Academic in Chemical Engineering.

[4][6] Bachelor of Chemistry from Universidade Brasil (2012) / Academic of Chemical Engineering.

[7] Master’s degree in Environmental Sciences; Specialization in Basing the Teaching Practice of the Teacher; Improvement in Magisterium; Graduation in Pedagogy; Degree in Physics.

Submitted: August, 2019.

Approved: September, 2019.